Antibacterial stainless steel applied to general surgical operating instrument

An antibacterial stainless steel, surgical instrument technology, applied in surgery, medical science and other directions, can solve problems such as environmental bacteriostatic or bactericidal effects that cannot truly reflect antibacterial, and achieve accurate directional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] Embodiment: the antibacterial stainless steel material is selected as 2Cr13Cu stainless steel.

[0018] This specific embodiment adopts the following technical scheme: the chemical composition of 2Cr13Cu stainless steel is calculated by weight percentage: C: 0.25%, Cr: 13.5%, Cu: 3.0%, and the balance is Fe; the sample size is 50×50×2mm.

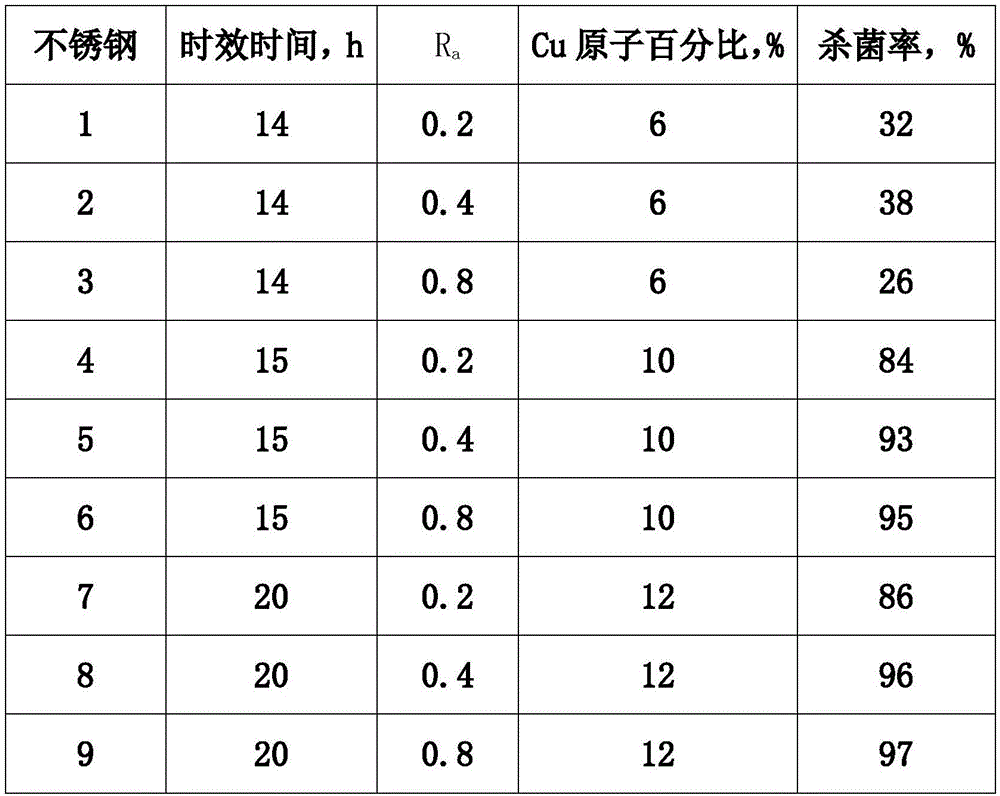

[0019] The heat treatment process is: solution treatment at 980°C±10°C for 1 hour, air cooling to room temperature, then heating up to 400°C for 14, 15 and 20 hours respectively, and air cooling to room temperature. The atomic percentage of antibacterial element Cu on the surface of the sample was tested by X-ray photoelectron spectroscopy.

[0020] Surface roughness: Antibacterial stainless steel samples with Ra of 0.2, 0.4 and 0.8 surface states were designed respectively.

[0021] Bacterial environment used: mixed bacteria of Staphylococcus aureus and Escherichia coli, the concentration was 2×10 4 CFU / mL. The antibacterial perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com