Ethyl alcohol processing method by clear solution of distiller grain and corn

A processing method and technology for clear liquid, which are applied in the fields of biochemical equipment and methods, liquid production bioreactors, bioreactors/fermenters for specific purposes, etc., can solve the problem of large loss rate of inorganic acid equipment and difficult processing of corn oil , the high price of corn, to achieve the effect of improving the saccharification rate, increasing the added value of the product, and reducing the saccharification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

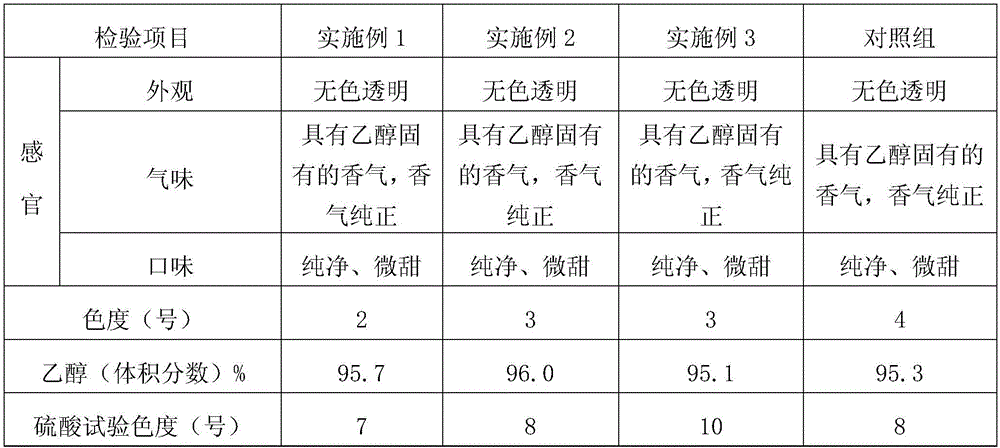

Embodiment 1

[0047] Mix the corn flour slurry after extracting part of the starch with the centrifuged clear liquid of spent distiller's grains discharged from the crude distillation tower to obtain a slurry with a corn starch concentration of 15%; add 10u / g of high-temperature-resistant α-amylase to the slurry Carry out precooking, the precooking temperature is 50°C, and the precooking time is 20 minutes. After the precooking is completed, it is heated to 95°C and maintained for 90 minutes in an aftercooker to obtain liquefied mash; the liquefied mash is pumped into the mash pot for saccharification to obtain mash mash. The amount of glucoamylase added is 200u / g, the saccharification temperature is 50°C, and the saccharification time is 20 minutes. Continuous fermentation is carried out in 5 fermentation tanks to obtain mature mash. g Add activated active dry yeast, after 12 hours of fermentation, divide about 1 / 3 of the mash from the first fermenter to the second fermenter, then refill th...

Embodiment 2

[0050] Mix the corn flour slurry after extracting part of the starch with the centrifuged clear liquid of spent distiller's grains discharged from the crude distillation tower to obtain a slurry with a corn starch concentration of 20%; add 15u / g of high-temperature-resistant α-amylase to the slurry Carry out precooking, the precooking temperature is 60°C, and the precooking time is 30 minutes. After the precooking is completed, it is heated to 105°C and maintained for 120 minutes in an aftercooker to obtain liquefied mash; the liquefied mash is pumped into the mash pot for saccharification to obtain mash mash. The amount of glucoamylase added is 250u / g. The saccharification temperature is 65°C and the saccharification time is 30 minutes. Continuous fermentation is carried out in 10 fermenters to obtain mature mash. g Add activated active dry yeast, after 16 hours of fermentation, divide about 1 / 3 of the mash from the first fermenter to the second fermenter, then refill the firs...

Embodiment 3

[0053]The corn flour slurry after extracting part of the starch is mixed with the centrifuged clear liquid of waste distiller's grains discharged from the crude distillation tower to obtain a slurry with a corn starch concentration of 17%; add 13u / g high temperature resistant α-amylase to the slurry Carry out precooking, the precooking temperature is 55°C, and the precooking time is 25 minutes. After the precooking is completed, it is heated to 100°C and maintained for 110 minutes in an aftercooker to obtain liquefied mash; the liquefied mash is pumped into the mash pot for saccharification to obtain mash mash. The amount of glucoamylase added is 220u / g. The saccharification temperature is 60°C and the saccharification time is 25 minutes. Continuous fermentation is carried out in 8 fermenters to obtain mature mash. g add activated active dry yeast, after 14 hours of fermentation, divide about 1 / 3 of the mash from the first fermenter to the second fermenter, and then refill the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com