Method for knocking out arcA to increase yield of Klebsiella 1,3-propylene glycol

A Klebsiella, propylene glycol technology, applied in the field of metabolic engineering, can solve problems such as limiting TCA cycle activity and affecting the regeneration of intracellular reducing power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

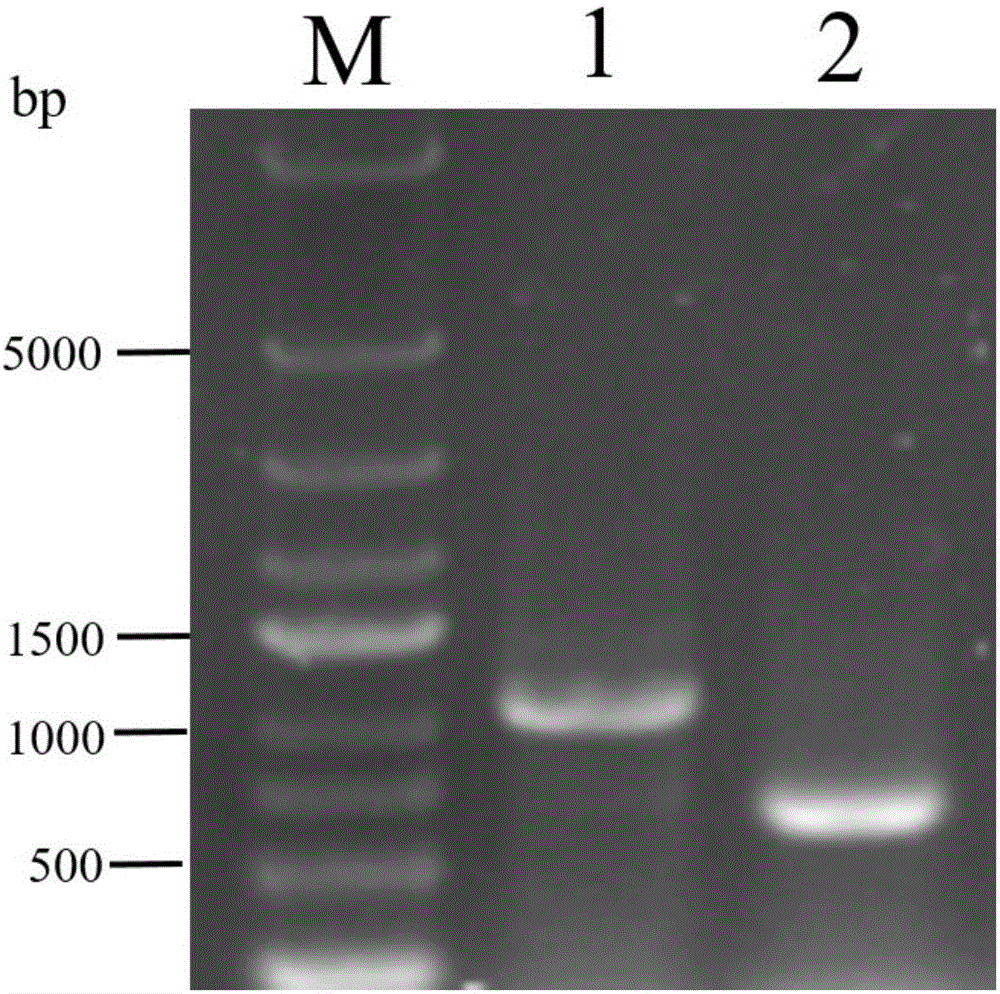

[0028] Example 1 This example illustrates the method for knocking out the arcA gene in K.pneumoniae using Red recombination technology

[0029] 1 K.pneumoniae was inoculated in liquid LB medium and cultured at 37°C until OD 600 =0.6, preparation of electrotransformation competent state.

[0030] 2 Introduce the pKD46 plasmid containing chloramphenicol resistance into K.pneumoniae competent, culture at 30°C for 12 hours, and transfer to liquid LB medium (containing chloramphenicol 30 μg L -1 ), cultured at 30℃ to OD 600 =0.25, add 30 mM arabinose, induce pKD46 plasmid to express Exo, Bet and Gam three proteins at 37°C, and prepare K.pneumonia (pKD46) competent again.

[0031] 3 Using the kanamycin-resistant pKD13 plasmid as a template, design amplification primers with arcA homologous fragments at both ends, and amplify to obtain linear DNA fragments. The primer sequences are as follows:

[0032] The upstream primer sequence is:

[0033] GGACTTTGGTACTTCCTGTTTCGATTTAGTTGGCA...

example 2

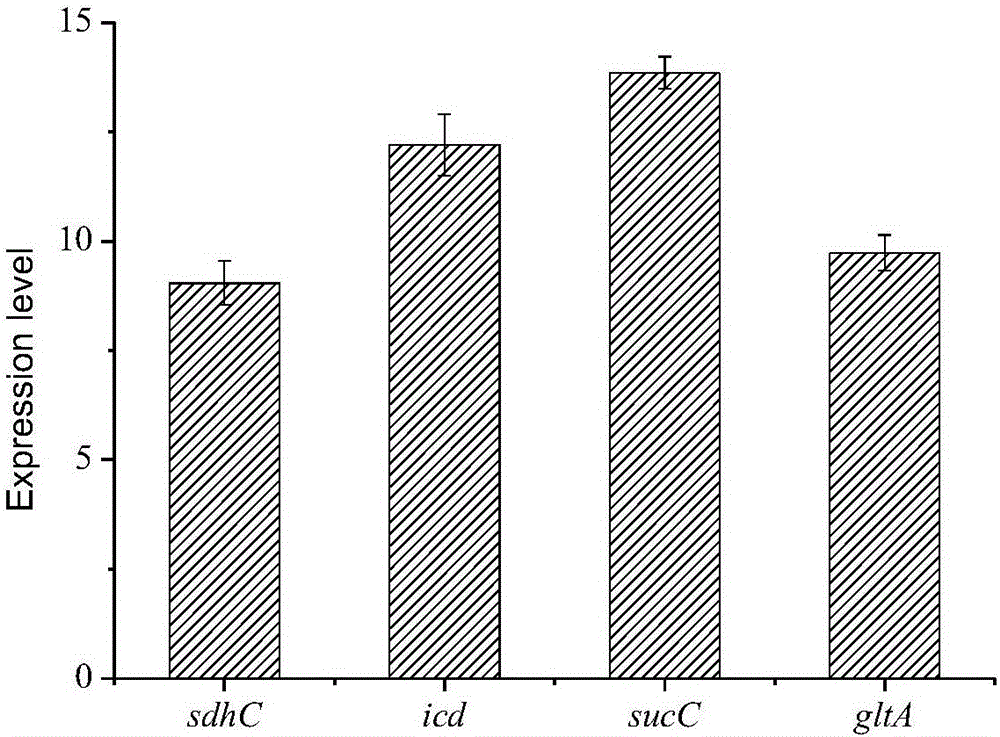

[0040] Example 2 Changes in transcription levels of key genes in the TCA cycle under microaerobic conditions after arcA gene knockout.

[0041] 1 Extraction of K.pneumoniae total RNA

[0042] (1) Grind the collected fresh bacteria immediately in liquid nitrogen.

[0043] (2) Add 1mL TRIzon to fully lyse the cells, and place at room temperature for 5 minutes to separate protein-nucleic acid complexes.

[0044] (3) Add 0.2 mL of chloroform to the solution in the upward step, cover the tube cap, shake vigorously for 15 s, and place at room temperature for 3 min.

[0045] (4) 4°C, 12000r·min -1 Centrifuge for 15 min, and transfer the upper aqueous phase to a new RNase-free centrifuge tube.

[0046] (5) Add an equal volume of isopropanol, pipette evenly, and place at room temperature for 10 minutes.

[0047] (6) 4°C, 12000r·min -1 Centrifuge for 10 min and discard the supernatant.

[0048] (7) Add 1 mL of RNase-free 75% ethanol to wash the precipitate.

[0049] (8) 4°C, 1200...

example 3

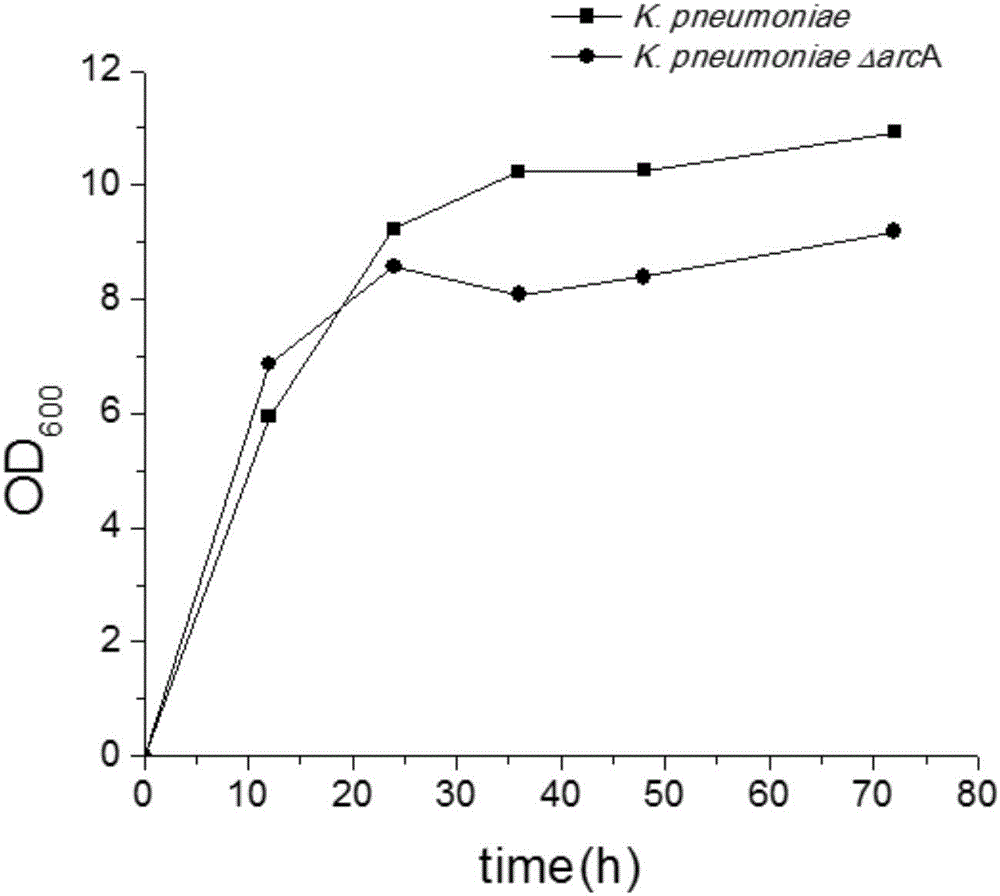

[0068] Example 3. Fermentation of 1,3-propanediol using constructed K.pneumoniaeΔarcA.

[0069] 1 Preparation of seed medium: yeast powder 10g L -1 , peptone 5g·L -1 , sodium chloride 10g·L -1 , the balance is water; fermentation medium: glycerol 40g L -1 , yeast powder 6g·L -1 , glucose 2g·L -1 , KH 2 PO 4 7.5g·L -1 , MgSO 4 2g·L -1 , (NH 4 ) 2 SO 4 2g·L -1 , FeSO 4 ·7H 2 O 0.005g·L -1 , VB 12 0.015g·L -1 , trace element solution (MnCl 2 4H 2 O 0.1g L -1 , Na 2 MoO 4 2H 2 O 0.035g·L -1 , CoCl 2 ·6H 2 O 0.2g·L -1 , ZnCl 2 0.07g·L -1 , CuCl 2 0.02g·L -1 , NiCl 2 ·6H 2 O 0.025g·L -1 , H 3 BO 3 0.06g·L -1 )100μL·L -1 , the balance is water, and KOH is used to adjust the pH to about 8.5.

[0070] 2 Inoculate K.pneumonia and the mutant strain obtained above in liquid LB medium, 37°C, 100r min -1 Shake culture for 16 hours, transfer to the seed medium according to the inoculum size of 0.5% (v / v), 37°C, 100r·min -1 Grow to OD 600 =3, tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com