Fast preparation method of TiB-TiC-TiB2-B4C composite ceramic

A technology of tib-tic-tib2-b4c and composite ceramics, which is applied in the field of functional protection material preparation, can solve the problems of high cost, low product density, complicated preparation process of C complex ceramics, etc. Simple and easy, high-density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

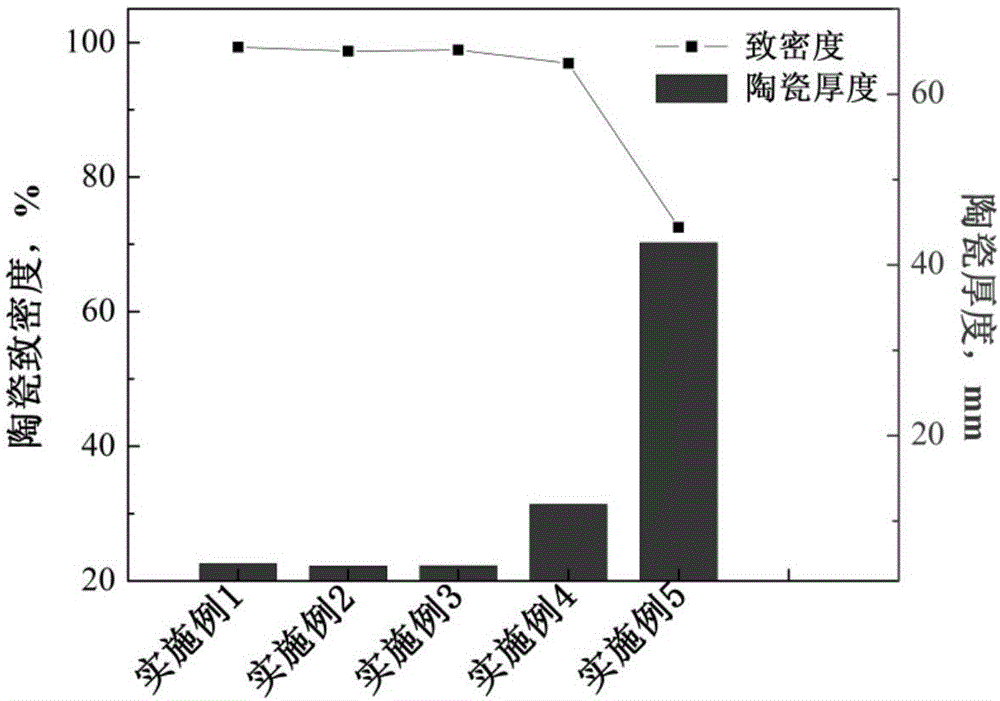

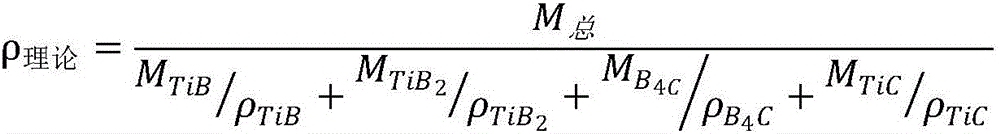

Examples

Embodiment 1

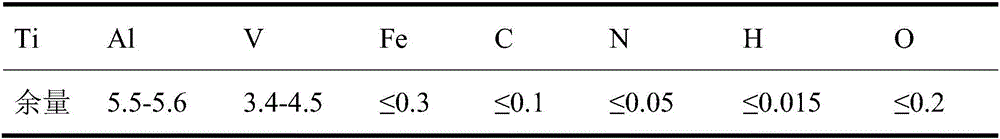

[0037] A kind of TiB-TiC-TiB 2 -B 4 The rapid preparation method of C composite ceramics, the method steps are as follows:

[0038] (1) 45.36g TC4 powder and 15.12g B 4 Add C powder in the ball mill tank of SM-QB planetary ball mill, and add balls and excess absolute ethanol according to the ball-to-material ratio of 3:1; at a speed of 300r / min, ball mill for 0.5h to obtain a mixed slurry; The mixed slurry is poured into a vacuum rotary evaporator, and steamed for 0.5 h at a speed of 100r / min and a water bath temperature of 80°C to obtain a mixed powder precursor; put the mixed powder precursor into an electric heating constant temperature blast drying box , dried at 60°C for 1 h to obtain a mixed powder.

[0039] Wherein, the grinding ball is composed of a large agate ball and a small agate ball with a mass ratio of 1:1; the diameter of the large agate ball is 10mm, and the diameter of the small agate ball is 5mm.

[0040](2) Put 60.48g of mixed powder into a graphite mol...

Embodiment 2

[0043] A kind of TiB-TiC-TiB 2 -B 4 The rapid preparation method of C composite ceramics, the method steps are as follows:

[0044] (1) 49.15g TC4 powder and 11.33g B 4 C powder is added in the ball mill tank of SM-QB planetary ball mill, and balls and excess absolute ethanol are added according to the ball-to-material ratio of 3:1; at a speed of 300r / min, ball mill for 1h to obtain mixed mud; Pour the mixed slurry into a vacuum rotary evaporator, and steam it for 0.5h under the conditions of a rotating speed of 80r / min and a water bath temperature of 80°C to obtain a mixed powder precursor; put the mixed powder precursor into an electric heating constant temperature blast drying box , and dried at 60°C for 1 h to obtain a mixed powder.

[0045] Wherein, the grinding ball is preferably composed of a large agate ball and a small agate ball with a mass ratio of 1:1; the diameter of the large agate ball is 10mm, and the diameter of the small agate ball is 5mm.

[0046] (2) Pu...

Embodiment 3

[0049] A kind of TiB-TiC-TiB 2 -B 4 The rapid preparation method of C composite ceramics, the method steps are as follows:

[0050] (1) 51.41g TC4 powder and 9.07g B 4 Add C powder in the ball mill tank of SM-QB planetary ball mill, and add balls and excess absolute ethanol according to the ball-to-material ratio of 3:1; at a speed of 300r / min, ball mill for 0.5h to obtain a mixed slurry; The mixed slurry is poured into a vacuum rotary evaporator, and steamed for 0.5 h at a speed of 80r / min and a water bath temperature of 80°C to obtain a mixed powder precursor; put the mixed powder precursor into an electric heating constant temperature blast drying box , dried at 60°C for 1 h to obtain a mixed powder.

[0051] Wherein, the grinding ball is preferably composed of a large agate ball and a small agate ball with a mass ratio of 1:1; the diameter of the large agate ball is 10mm, and the diameter of the small agate ball is 5mm.

[0052] (2) Put 60.48g of mixed powder into a gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com