Method for comprehensive treatment and recycling of ammonium sulfate wastewater of rare-earth smelting

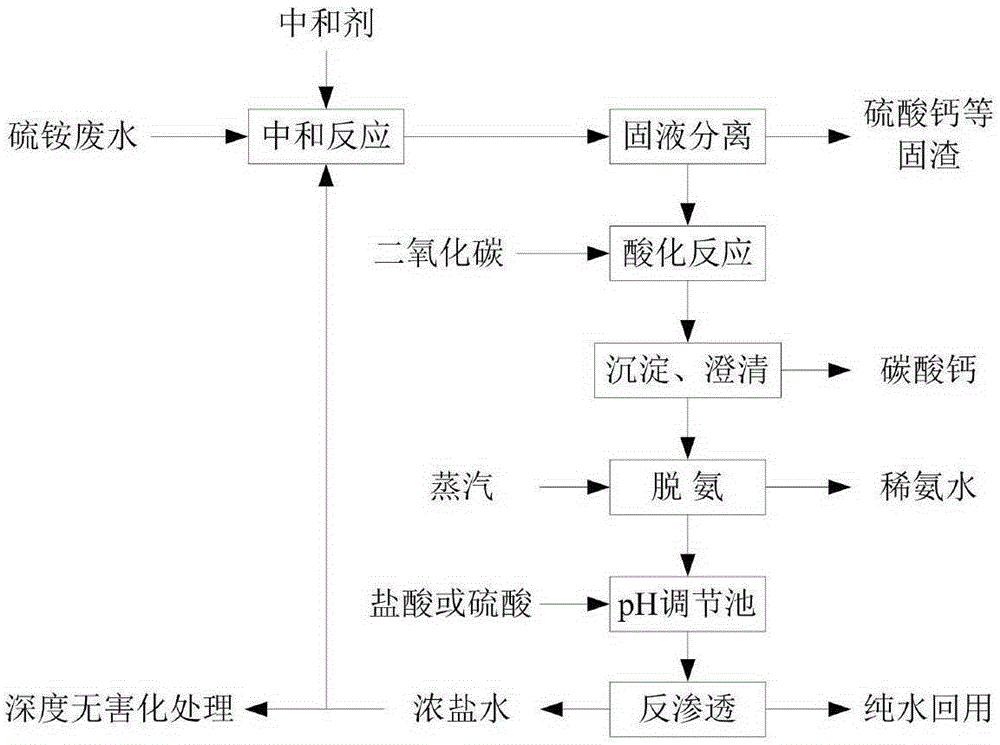

A comprehensive wastewater treatment technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of large fluctuations in the water quality of ammonium sulfate wastewater, the inability to effectively reduce the hardness of wastewater, and equipment Scaling can not run stably and other problems, to achieve the effect of economical and effective wastewater treatment and reuse, good social and economic benefits, and reduce treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Carbon-precipitated ammonium sulfate wastewater from a northern rare earth enterprise, wastewater quality: total hardness 130-230mmol / L, ammonia nitrogen 3500-5000mg / L, conductivity 30,000-50,000μs / cm, pH6-8, sulfate radical 21000-32000mg / L, salinity 3%-4.5%.

[0032] Add lime to the rare earth smelting ammonium sulfate wastewater while stirring, that is, a large amount of white precipitate appears, continue to add lime to stabilize the pH of the wastewater at 11; The sediment at the bottom of the pool is sent to the plate and frame filter by a mud pump for filtration, and the obtained filtrate and supernatant are combined; carbon dioxide gas is added to the clear liquid obtained by the neutralization reaction, and the amount of carbon dioxide added is 0.2m 3 per ton of water (standard state), the reaction time was 2 hours, and white calcium carbonate crystals were separated out at this moment; the suspension after the acidification reaction finished entered the floati...

Embodiment 2

[0034] Carbon-precipitated ammonium sulfate wastewater from a northern rare earth enterprise, wastewater quality: total hardness ≥ 200mmol / L, ammonia nitrogen 3500-5000mg / L, conductivity 3-50,000μs / cm, pH6-8, sulfate radical 21000-32000mg / L, Salinity 3%-4.5%.

[0035] Add calcium hydroxide to the rare earth smelting ammonium sulfate wastewater while stirring until the pH of the wastewater reaches 14, stop stirring to precipitate insoluble solid particles such as calcium sulfate, collect the supernatant, and send the bottom sediment to a plate and frame filter for filtration to obtain sulfuric acid Calcium and other solid residues, the supernatant and supernatant obtained by filtration are combined; carbon dioxide gas is added to the combined supernatant, and the amount of carbon dioxide added is 0.4m 3 / ton of water (standard state) and maintain the reaction for 0.5 hours, the acidification reaction forms a calcium carbonate precipitate, and the suspension is sent to a floati...

Embodiment 3

[0037] Carbon-precipitated ammonium sulfate wastewater from a rare earth enterprise, wastewater quality: total hardness ≥ 200mmol / L, ammonia nitrogen 3500-5000mg / L, conductivity 30,000-50,000μs / cm, pH6-8, sulfate radical 21000-32000mg / L, Salinity 3%-4.5%.

[0038]Add lime to the rare earth smelting ammonium sulfate wastewater and stir until the neutralization reaction is completed when the reaction pH is 13, and the suspension containing calcium sulfate is sent to a plate and frame filter for filtration to obtain clear liquid and solid residues such as calcium sulfate; Add carbon dioxide gas to the water, the amount of carbon dioxide added is 0.3 3 / ton of water (standard state), the reaction time was 1.2 hours, and the acidification reaction formed calcium carbonate precipitation, and the suspension was sent to the floating flow type sedimentation tank for precipitation for 5 hours to obtain clarified liquid, and the bottom precipitation was sent to filter to obtain solid ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com