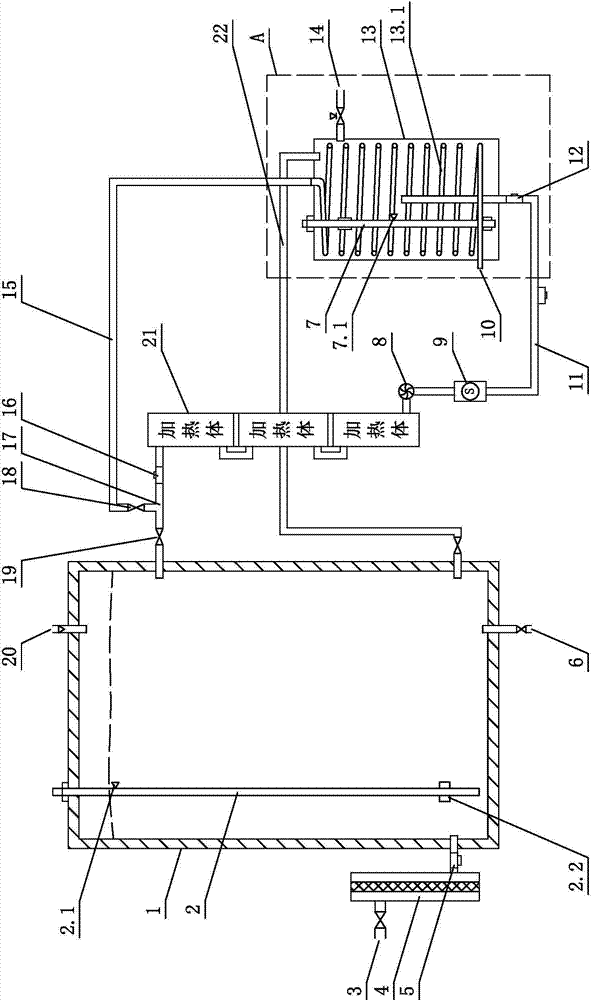

Carbon fiber instant-heating-type water boiler

An instant, carbon fiber technology, used in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of difficult discharge of scale, affecting drinking water health, and low heating efficiency, achieving high heating efficiency and ensuring drinking water. Healthy, reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

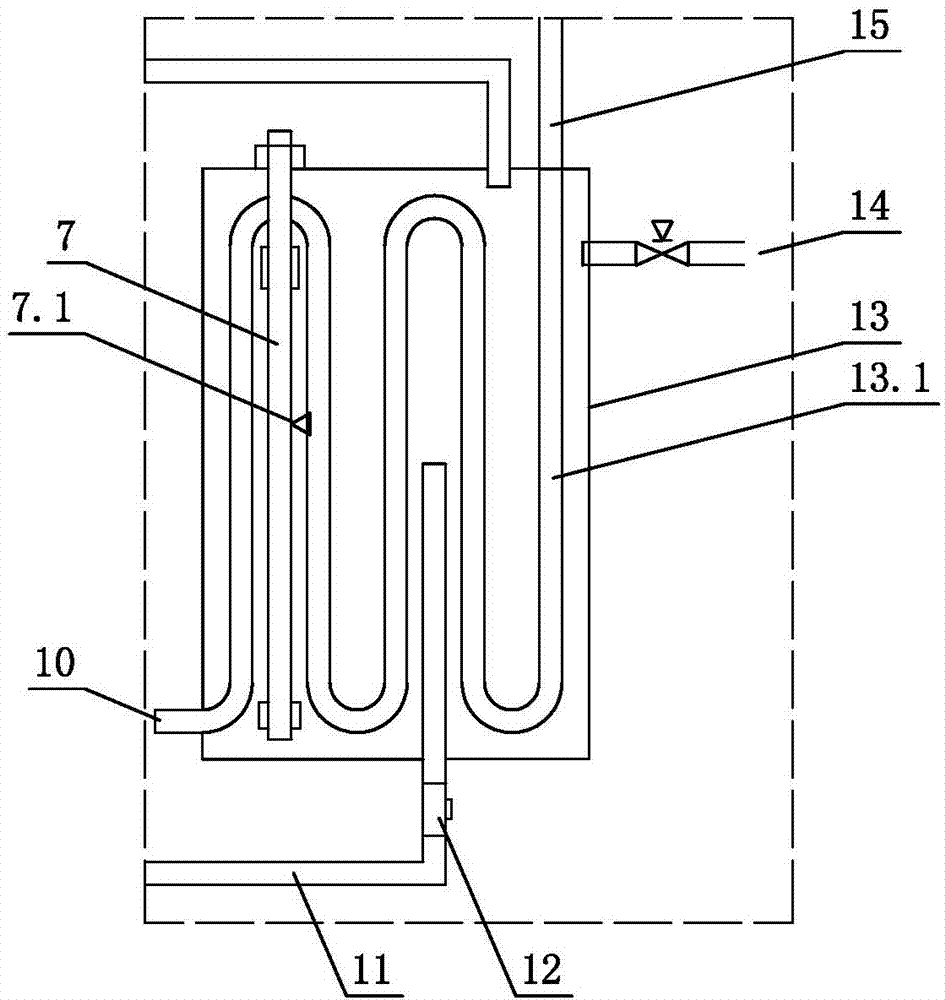

[0041] see figure 2 , this carbon fiber instant water boiler is different from the first embodiment in that: the heat exchange tube 13.1 in the heat exchanger 13 is arranged in a shape bent back and forth to increase the heat exchange tube 13.1 in the heat exchange tube The length within 13 makes the internal boiled water cool down through heat exchange.

[0042] Other parts not described are the same as those of the first embodiment, and will not be analyzed and described here.

no. 3 example

[0044] This carbon fiber instant water boiler is different from the first embodiment in that: the capacity of the heat preservation water tank 1 is 30L, and only one set of heating bodies 21 can be used for the heat preservation water tank 1 of this small capacity. The small-capacity carbon fiber instant water boiler is suitable for ordinary families or other places with less water intake.

[0045] Other parts not described are the same as those of the first embodiment, and will not be analyzed and described here.

no. 4 example

[0047] This carbon fiber instant water boiler differs from the first embodiment in that: the thermal insulation water tank 1 has a capacity of 50 L, and two sets of heating bodies 21 can be used for the thermal insulation water tank 1 of medium capacity. This medium-capacity carbon fiber instant water boiler is suitable for companies or other places where water intake is relatively small.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com