Flexible generation device through adoption of industrial waste heat and manufacturing method thereof

A technology for power generation devices and industrial waste heat, which can be applied to thermoelectric devices, thermoelectric devices, generators/motors, etc. with thermal changes in dielectric constant, which can solve the problems of flexible power generation devices that can not meet the requirements of industrial waste heat conversion, and achieve improved thermal-electricity. Conversion efficiency, effect of improving temperature change rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for manufacturing a flexible power generation device utilizing industrial waste heat, comprising the following steps:

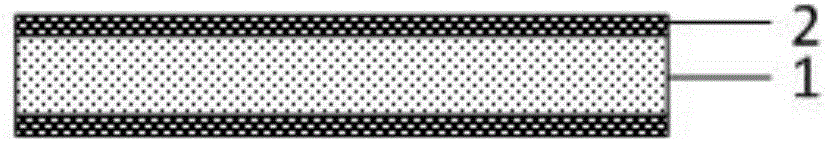

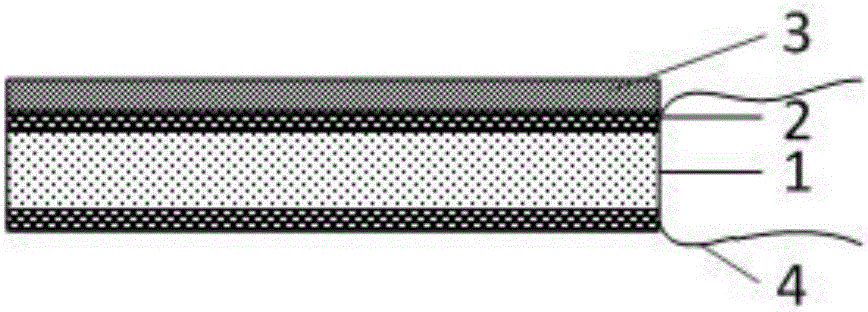

[0028] 1) Refer to figure 2 On the upper and lower sides of the pyroelectric film 1, prepare the upper layer of film electrodes 2 by wet transfer method, and fix the copper wire 4 on the upper and lower film electrodes 2 with conductive silver paste. The pyroelectric film 1 is a PVDF film with a thickness of 100 μm , the film electrode 2 is made of graphene to obtain a flexible heat collection device; the supercapacitor film 3 is connected in parallel with the flexible heat collection device, and the positive and negative electrodes are drawn out through the copper wire 4 to obtain a flexible power generation unit;

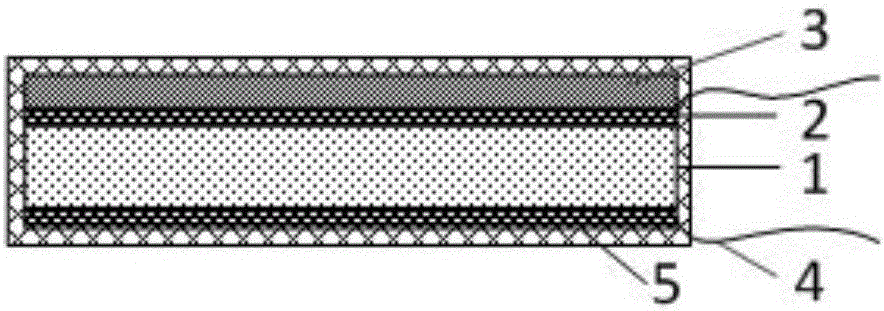

[0029] 2) By drip coating, PDMS with a mass fraction of 10% is dropped on the flexible power generation unit, so that the flexible power generation unit is completely surrounded by the PDMS film 5, and only the copper wire 4 is e...

Embodiment 2

[0033] A method for manufacturing a flexible power generation device utilizing industrial waste heat, comprising the following steps:

[0034] 1) Refer to figure 2 , on the upper and lower sides of the pyroelectric film 1, prepare the upper layer of film electrodes 2 by sputtering method, and fix the copper wire 4 on the upper and lower film electrodes with conductive silver paste, and the pyroelectric film 1 is a PMN-PT film with a thickness of 30 μm , the material of the film electrode 2 is a metal film, and the material is Au to obtain a flexible heat collection device; the supercapacitor film 3 is connected in parallel with the flexible heat collection device, and the positive and negative electrodes are drawn out through the copper wire 4 to obtain a flexible power generation unit;

[0035] 2) By drip coating, PDMS with a mass fraction of 10% is dropped on the flexible power generation unit, so that the flexible power generation unit is completely surrounded by the PDMS ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com