A kind of preparation method of flexible pyroelectric sensitive film with microstructure

A sensitive film and pyroelectric technology, applied in the field of infrared sensors, can solve problems such as depolarization of sensitive materials, achieve the effect of increasing the temperature change rate, improving the pyroelectric response signal of the device, and increasing the heat flow component

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A method for preparing a flexible pyroelectric sensitive film with a microstructure, comprising the following steps:

[0033] Step 1: Configure pyroelectric polymer solution;

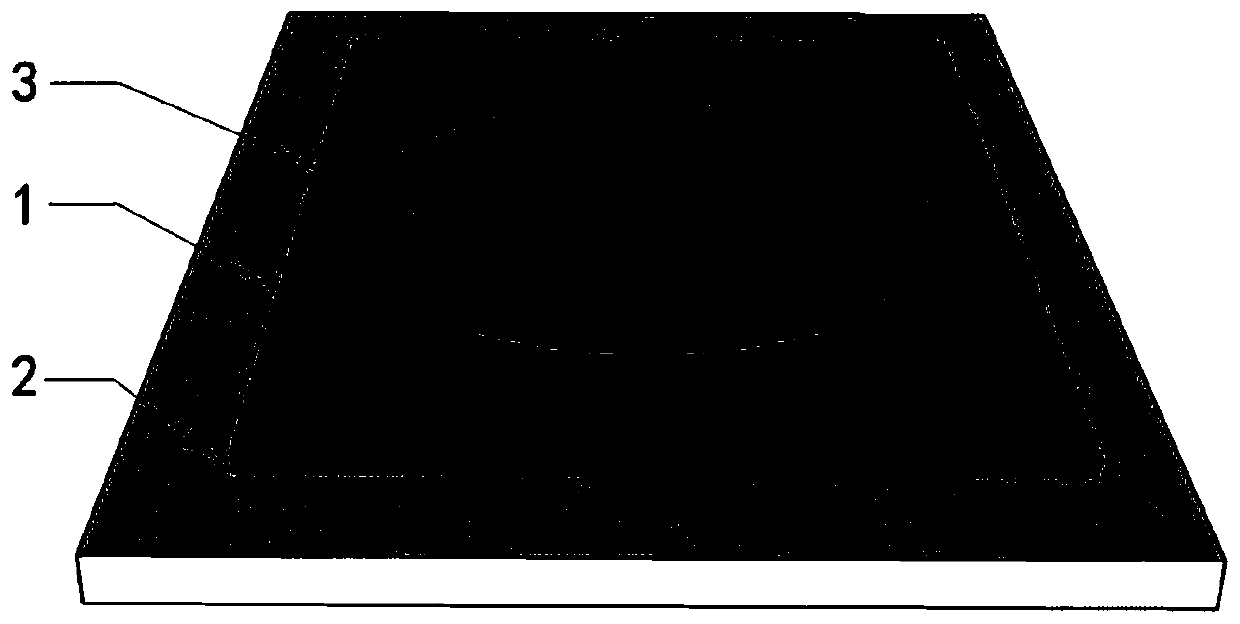

[0034] Step 2: cast the solution onto the casting plate 1 for the first time, and form a thin film 3 after the solvent evaporates;

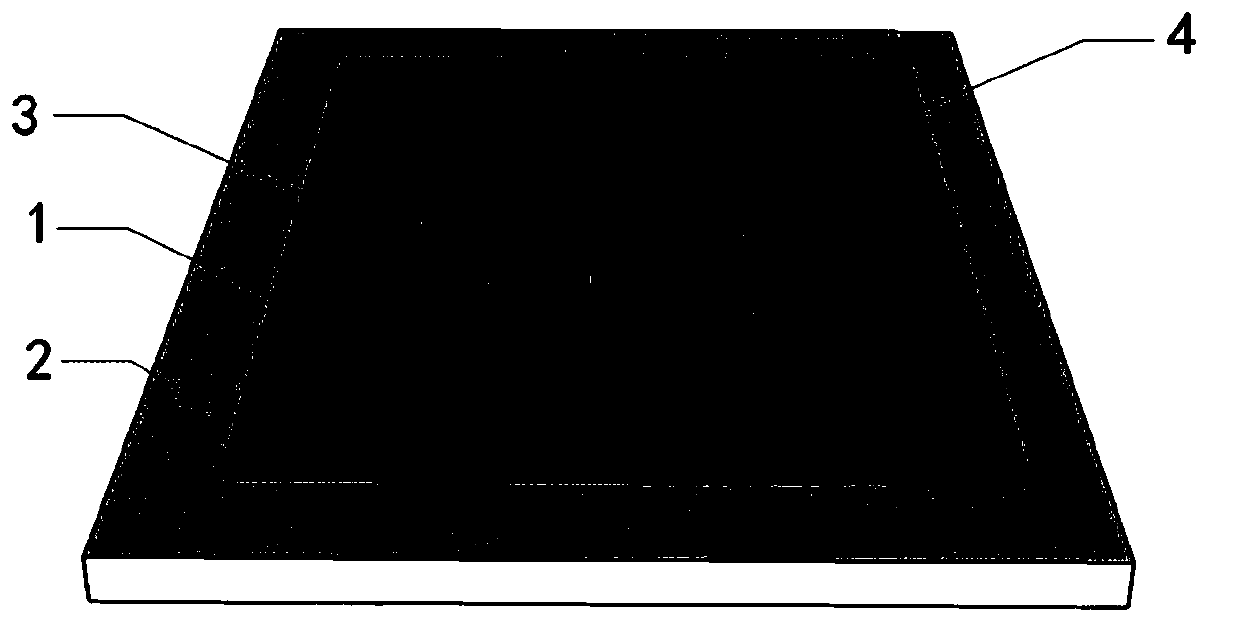

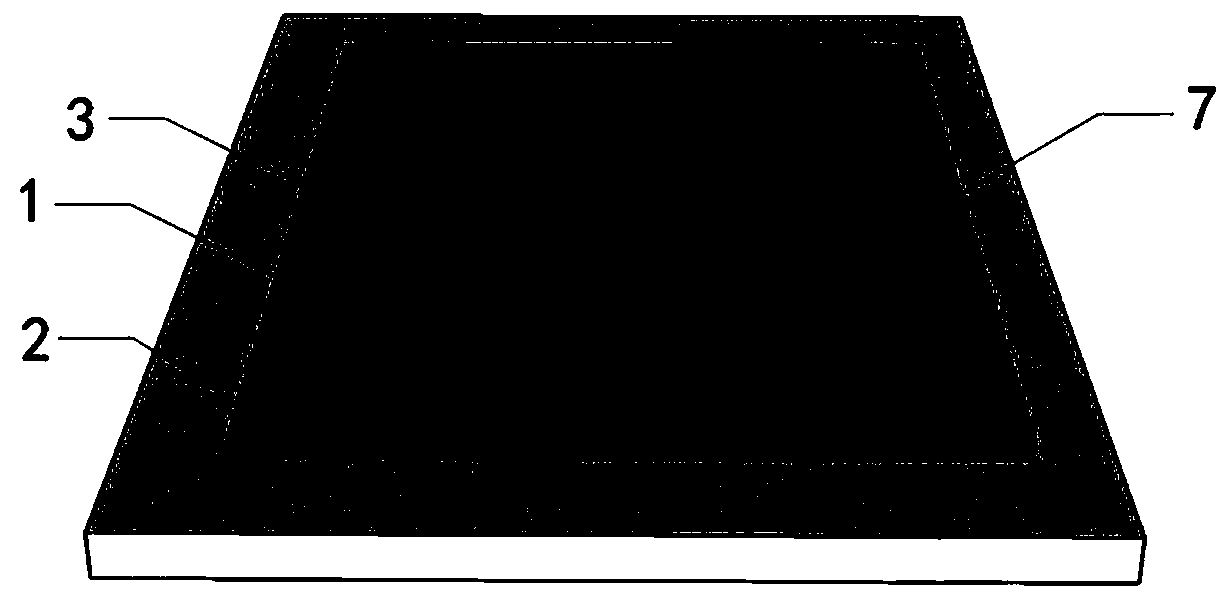

[0035] Step 3: performing a second casting of the solution on the film 3 by screen printing, and forming a film microstructure 7 after the solvent volatilizes;

[0036] Step 4: Remove the screen printing screen 4 to obtain a flexible pyroelectric sensitive film with a microstructure.

[0037] In the step 1, the mass percentage of the pyroelectric polymer solution is 4wt%-30wt%.

[0038] The thickness of the thin film 3 in step 2 and the thin film microstructure 7 in step 3 is 10 μm-100 μm.

[0039] The specific steps of the screen printing method in the step 3 are: the lower surface of the screen printing screen 4 is close to the upper surface of the film 3; the ...

specific Embodiment 1

[0041] Step 1: Prepare Pyroelectric Polymer Solution

[0042] Dissolving the pyroelectric polymer powder or granules into the solvent, heating and stirring in a water bath for 2 hours to 12 hours to obtain a pyroelectric polymer solution with a concentration percentage of 4wt%-30wt%.

[0043] Step 2: Device Preparation

[0044] The device consists of a casting plate 1, a constant temperature heating table 2, a screen printing screen 4, and a rubber scraper, wherein the casting plate 1, the screen printing screen 4, and the rubber scraper need to be mixed with acetone and alcohol in a 1:1 ratio The water in the solution was ultrasonically treated for 15 minutes to ensure its cleanliness.

[0045] Step 3: Preparation of flexible pyroelectric sensitive film with microstructure 3

[0046] Select the type of pyroelectric polymer material and the type of solvent according to the needs, configure the concentration of the pyroelectric polymer solution according to the needs, cast th...

specific Embodiment 2

[0050] Step 1: Prepare a pyroelectric polymer solution, dissolve PVDF (polyvinylidene fluoride) powder in 2-methylpyrrolidone (NMP) solvent, the mass ratio of solute to solvent is 20:80, heat in a water bath at 70°C and magnetically Stir for 12 hours to dissolve PVDF evenly.

[0051] Step 2: Place a casting plate 1, cast the pyroelectric polymer solution on the casting plate 1, place it on a constant temperature heating table 2 at 60°C, adjust the constant temperature heating table 2 to the level, and volatilize the solvent, complete Cast film forming for the first time to obtain a film 3 with a thickness of 10 μm (such as figure 1 shown).

[0052] Step 3: Attach the lower surface of the screen printing screen 4 (groove pattern, groove width and groove interval are both 300 μm) to the film 3 (such as figure 2 As shown), the pyroelectric polymer solution 1 is cast on the upper surface of the screen printing screen 4, and the solution cast for the second time is pressed into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com