A kind of natural plant thickener for spraying and its preparation method

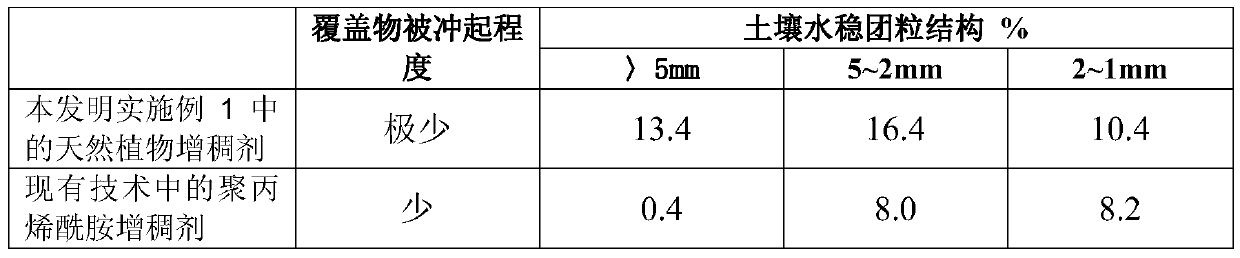

A natural plant and thickener technology, applied in the direction of chemical instruments and methods, applications, fertilizer mixtures, etc., can solve the problems of low bonding strength, poor performance stability, and high production cost of natural plant thickeners, and improve soil water retention and corrosion resistance, good performance stability and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Specifically, the preparation method of the natural plant thickener for spraying can include: comprising the following steps:

[0031] Step A, crushing and sieving the endosperm of plant seeds by superfine milling, so as to obtain plant endosperm powder with a water content of 10% to 15% and a fineness greater than or equal to 40 mesh. Wherein, the plant seed endosperm is the seed endosperm of at least one of tara, gourd, tamarind or guar bean. The ultra-fine pulverization can be completed by using a super-fine pulverizer in the prior art.

[0032] Step B, in parts by weight, put 75-99 parts of plant endosperm powder prepared in step A, 0.3-8 parts of dextrin, 0.04-9 parts of sodium tetraborate and 0.1-12 parts of potassium sorbate into the mixture mixing in a tank (preferably uniformly mixing in a closed aseptic mixing tank), and the mixing time is 25 to 40 minutes, so as to prepare the natural plant thickener.

[0033] Step C, adjusting the moisture content of the n...

Embodiment 1

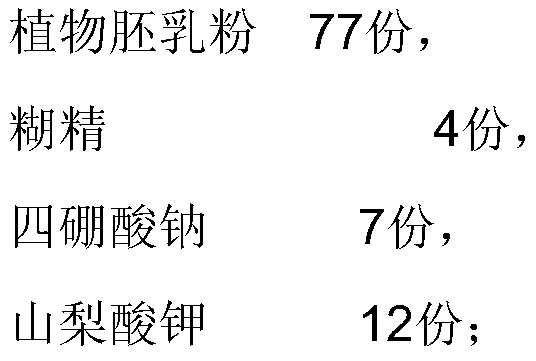

[0047] A kind of natural vegetable thickener for spraying, is made of the following components by weight:

[0048]

[0049] Wherein, the plant endosperm powder is the endosperm powder of tara seeds with a fineness of 100 mesh.

[0050] Specifically, the preparation method of the natural plant thickener for spraying provided by Example 1 of the present invention comprises the following steps:

[0051] Step a1, crushing the endosperm of Tara seed by using an ultra-fine milling machine, and sieving to obtain Tara endosperm powder with a moisture content of 10% to 15% and a fineness of 100 mesh.

[0052] Step b1, according to parts by weight, put 77 parts of tara endosperm powder prepared in step a1, 4 parts of dextrin, 7 parts of sodium tetraborate and 12 parts of potassium sorbate into the mixing tank and put them in a closed Mix evenly under the condition of bacteria, the stirring speed of the mixing tank is 20rpm, and the mixing time is 30 minutes, so as to prepare the nat...

Embodiment 2

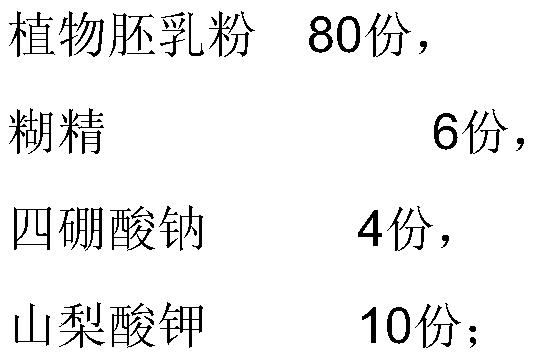

[0060] A kind of natural vegetable thickener for spraying, is made of the following components by weight:

[0061]

[0062] Wherein, the plant endosperm powder is the endosperm powder of gourd bean seeds with a fineness of 80 mesh.

[0063] Specifically, the preparation method of the natural plant thickener for spraying provided by the embodiment of the present invention 2 comprises the following steps:

[0064] Step a2: Grinding and sieving the endosperm of the gourd bean seeds with an ultra-fine milling machine to obtain the gourd bean endosperm powder with a moisture content of 10% to 15% and a fineness of 80 mesh.

[0065] Step b2, according to parts by weight, put 80 parts of Huli bean endosperm powder prepared in step a2, 6 parts of dextrin, 4 parts of sodium tetraborate and 10 parts of potassium sorbate into the mixing tank and put them under closed aseptic conditions Under uniform mixing, the stirring speed of the mixing tank is 20rpm, and the mixing time is 35 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com