Fluo-germanate red fluorescent material for white LED (light-emitting diode) and preparation method of material

A technology of fluorogermanate and red light fluorescence, which is applied in the direction of luminescent materials, chemical instruments and methods, sustainable buildings, etc., can solve the problems of difficult to control the valence state of Mn, low light efficiency of WLED, unsuitable for industrial production, etc., to achieve Easy to industrialized production, low equipment requirements, pure red light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] K 2 MnF 6 Powder preparation:

[0037] Weigh 2.25 g KMnO 4 Dissolve the powder in 150 ml HF (49wt%) aqueous solution, stir evenly, then add 45 gKHF 2 powder, continue to stir for 40 min (stirring speed is 1000r / min), then rapidly cool to 4 °C with ice water, add 4 ml H 2 o 2 (49wt%) aqueous solution, the color of the reactant solution gradually becomes lighter from purple until it is brownish yellow to obtain K 2 MnF 6 The suspension was left to stand for 4 h, centrifuged and washed 3 times with acetone (centrifugal speed: 4000r / min), and dried at 70 °C for 6 h to obtain K 2 MnF 6 Powder, spare.

Embodiment 2

[0039] QUR 6 :0.5%Mn 4+ Preparation of red fluorescent materials:

[0040] 0.0062 g K 2 MnF 6 powder and 0.5232 g GeO 2 The powder was dissolved in 10 ml of hydrofluoric acid (49wt.%) and stirred for 5 minutes (the stirring speed was 1000 r / min) to obtain a yellow solution; then 1.0447 g of RbF powder and 0.5810 g of KF powder were added to the solution , continue to stir at room temperature for 30 minutes (stirring speed is 1000 r / min), rapidly cool to 5 °C, let stand for 10 h, and then wash with acetone centrifuge for 3 times (centrifugal speed is 4000 r / min), and then in 80 ℃ drying for 6 h to obtain the red fluorescent material KRbGeF 6 :0.5%Mn 4+ .

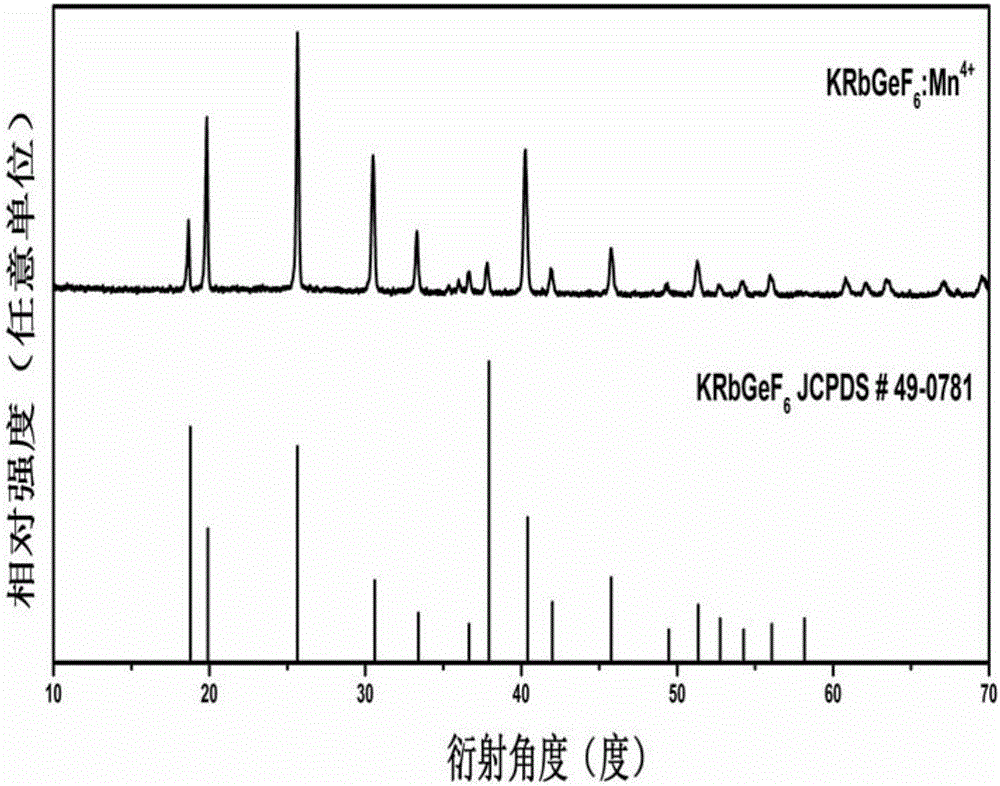

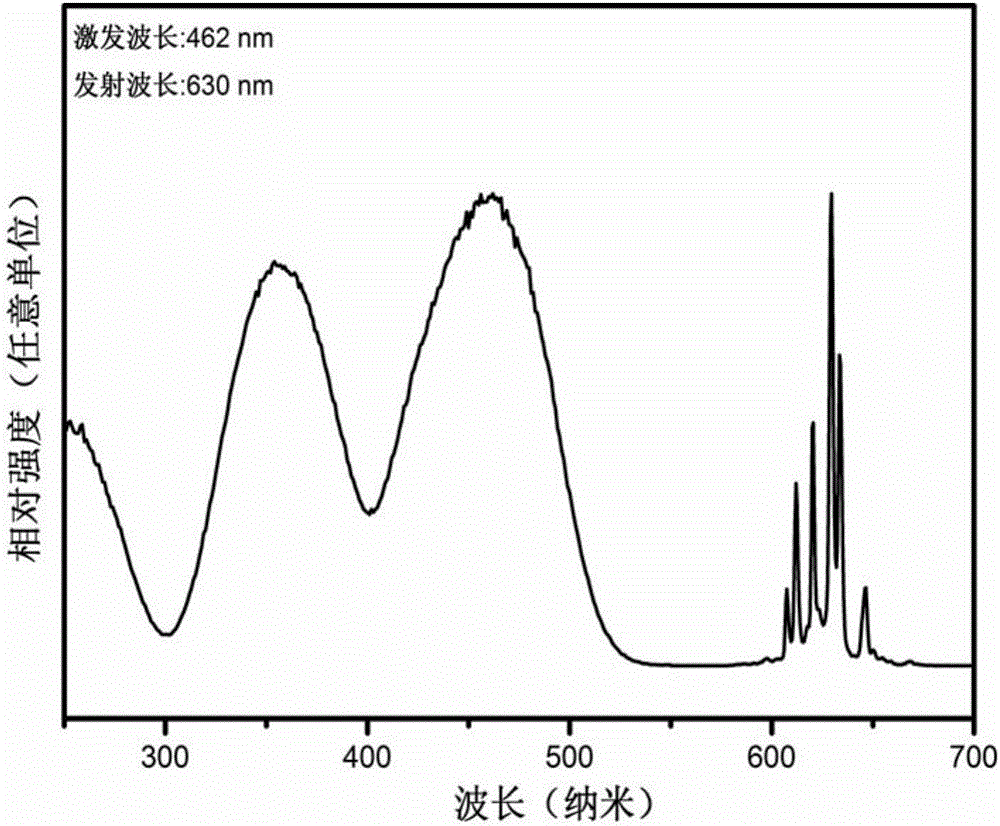

[0041] The red fluorescent material KRbGeF 6 :0.5%Mn 4+ There is a broad absorption band in the violet region and the blue region, located at 360 nm and 462 nm respectively, among which the absorption band in the blue region is the strongest (462 nm), which can completely match the blue light emitted by the GaInN chi...

Embodiment 3

[0043] QUR 6 :1%Mn 4+ Preparation of red fluorescent materials:

[0044] 0.0124 g K 2 MnF 6 powder and 0.5232 g GeO 2 The powder was dissolved in 10 ml of hydrofluoric acid (49wt.%) and stirred for 5 minutes (the stirring speed was 1000 r / min) to obtain a yellow solution; then 1.0447 g of RbF powder and 0.5810 g of KF powder were added to the solution , continue to stir at room temperature for 10 minutes (stirring speed is 400 r / min), rapidly cool to 0 °C, let stand for 5 h, and then wash with acetone centrifuge three times (centrifugal speed is 1000 r / min), and then in 60 ℃ drying for 2 h to obtain the red fluorescent material KRbGeF 6 :1%Mn 4+ .

[0045] The red fluorescent material KRbGeF 6 :1%Mn 4+ There is a broad absorption band in the violet region and the blue region, located at 360 nm and 462 nm respectively, among which the absorption band in the blue region is the strongest (462 nm), which can completely match the blue light emitted by the GaInN chip; its e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com