Water-based sealing compound adhesive emulsion and preparation method thereof

A sealing glue and adhesive technology, applied in the directions of adhesives, adhesive additives, adhesive types, etc., can solve the problems of pulverization, water-based sealing glue can not form a film, film cracks of water-based sealing glue, etc. The effect of water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

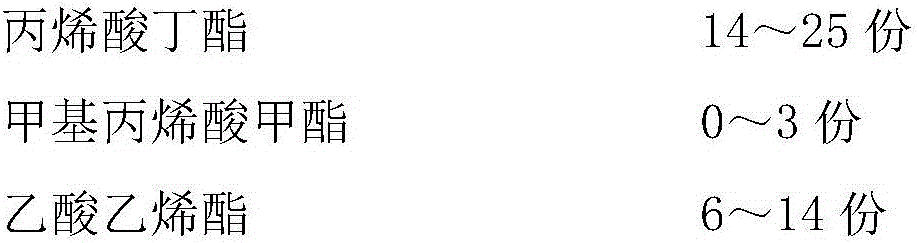

[0036] Weigh each reagent according to the following mass parts:

[0037]

[0038]

[0039] 1) First, add 20 parts of deionized water into the reactor, add 1 part of polyvinyl alcohol under stirring to disperse evenly, and then gradually heat up to 95°C to completely dissolve the polyvinyl alcohol.

[0040] 2) Lower the temperature to 60°C, add 0.04 part of sodium bicarbonate buffer, 0.5 part of emulsifier (the alkyl alcohol polyether type emulsifier and anionic emulsifier are compounded in a ratio of 2:3), stir and disperse evenly.

[0041] 3) get 7 parts of butyl acrylate, 3.5 parts of vinyl acetate, 0.35 part of methacrylic acid, 0.35 part of hydroxypropyl acrylate, 0.7 part of methyl methacrylate and mix to obtain a core monomer,

[0042] 4) Take 3 parts of core monomers and add them to the reactor containing the primer solution for pre-emulsification to obtain a pre-emulsion solution

[0043] 5) heating up, dripping 0.05 part of initiator in the reactor to initiate...

Embodiment 2

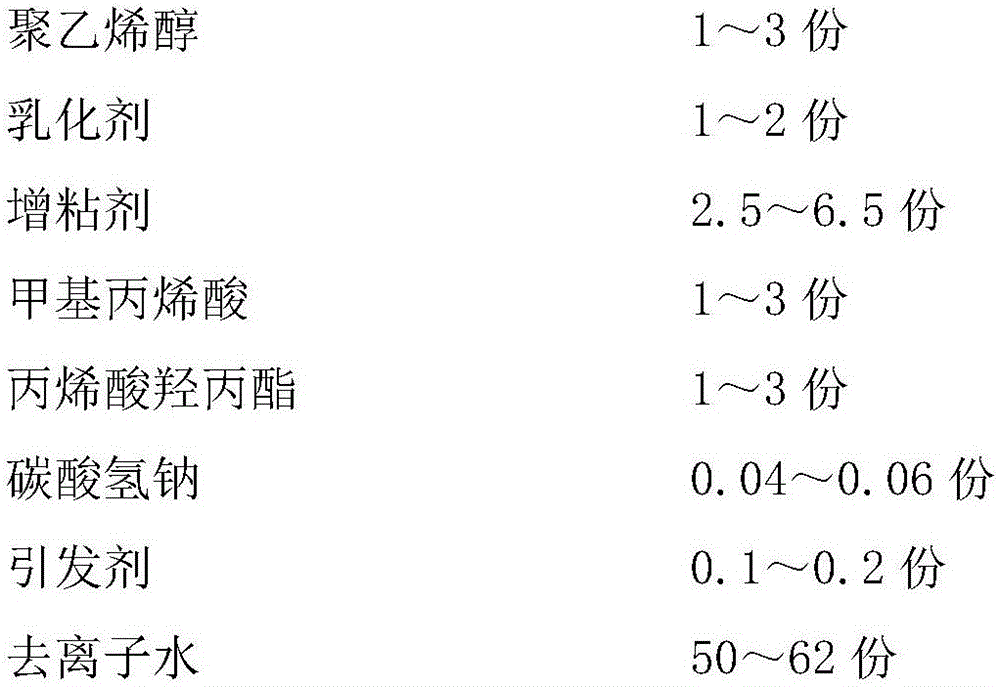

[0051] Weigh each reagent according to the following mass parts:

[0052]

[0053]

[0054] 1) First, add 30 parts of deionized water into the reactor, add 3 parts of polyvinyl alcohol under stirring to disperse evenly, and then gradually heat up to 95°C to completely dissolve the polyvinyl alcohol.

[0055] 2) Lower the temperature to 60°C, add 0.06 part of sodium bicarbonate buffer, 1 part of emulsifier (the alkyl alcohol polyether type emulsifier and anionic emulsifier are compounded in a ratio of 2:3), stir and disperse evenly.

[0056] 3) Mix 10 parts of butyl acrylate, 6 parts of vinyl acetate, 0.3 parts of methacrylic acid, 0.3 parts of hydroxypropyl acrylate, and 0.6 parts of methyl methacrylate to obtain a core monomer,

[0057] 4) Take 5 parts of core monomers and add them into the reactor containing the primer solution for pre-emulsification to obtain a pre-emulsion solution

[0058] 5) heating up, dripping 0.04 part of initiator in the reactor to initiate se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com