Preparation method of photo-induced repair microcapsules

A microcapsule and light-induced technology, applied in the field of metal anti-corrosion, can solve the problem of the release rate of the capsule core, etc., and achieve the effect of easing the adjustment process, appropriate reaction rate, and precise pH adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

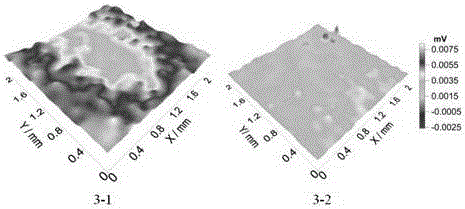

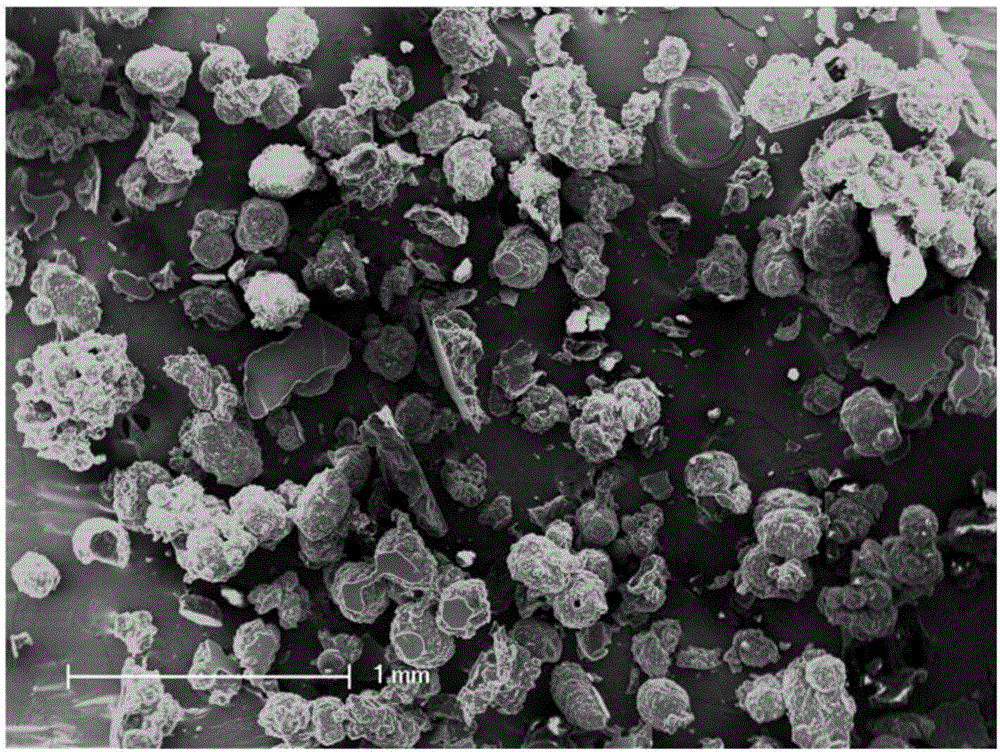

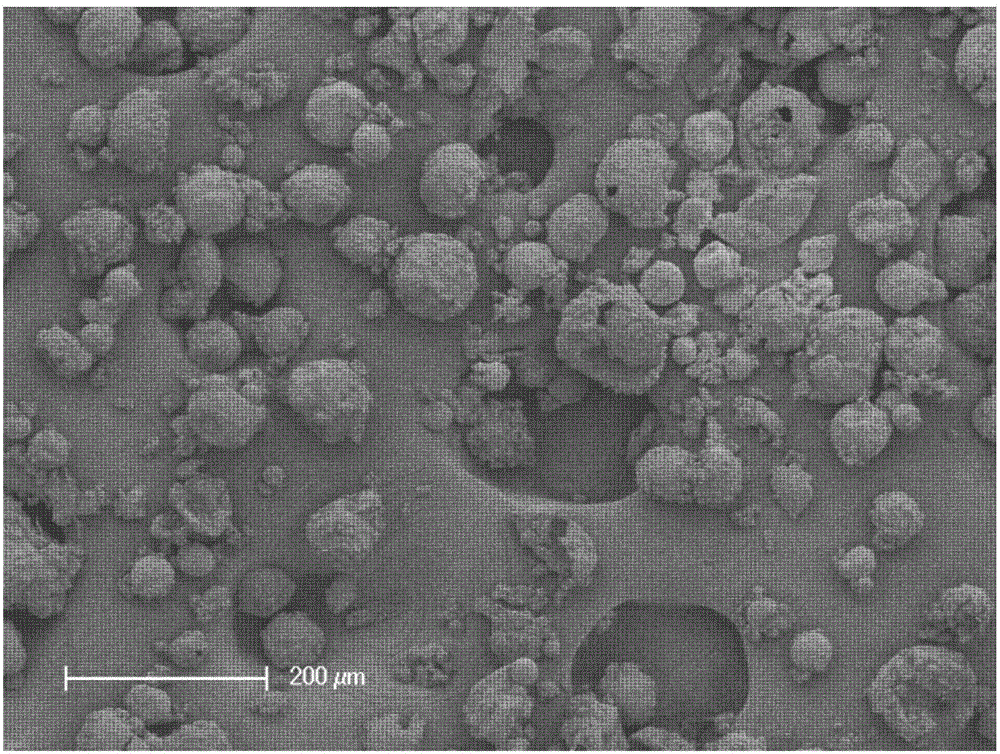

Image

Examples

Embodiment 1

[0032] The preparation of photoinduced self-healing microcapsules comprises the following steps:

[0033] (1) In a water bath at 45°C, 9.06g of chromone coumarin and 0.1g of sodium lauryl sulfate were emulsified for 25 minutes under stirring conditions, and 30g of distilled water was added dropwise to it, and 1-2 drops were added during the emulsification process The defoamer n-octanol reduces the surface activation energy of the capsule core material emulsion, making the capsule core material more stable and easy to be coated, thereby obtaining the capsule core material emulsion;

[0034] (2) Mix 5.35 g of urea and 12.57 g of formaldehyde solution with a mass concentration of 37%, adjust the pH of the mixture to 8 with triethanolamine, react for 1 hour at a temperature of 60° C., and then add 30 g of distilled water to form an interface Mixed solution to obtain a capsule wall prepolymer material solution;

[0035] (3) Pour the emulsified capsule core material emulsion into a...

Embodiment 2

[0038] The preparation of photoinduced self-healing microcapsules comprises the following steps:

[0039](1) In a water bath at 50°C, 12.08g of sesquiterpene coumarin and 0.12g of sodium lauryl sulfate were emulsified for 30min under stirring conditions, and 40g of distilled water was added dropwise to it. During the emulsification process, 1-2 Drop the defoamer n-octanol to reduce the surface activation energy of the capsule core material emulsion, making the capsule core material more stable and easy to be coated, thus obtaining the capsule core material emulsion;

[0040] (2) Mix 6.35g of urea with 13.57g of formaldehyde solution with a mass concentration of 37%, adjust the pH of the mixture to 8.5 with triethanolamine, react for 1.5h at a temperature of 70°C, and then add 40g of distilled water to form The interfacial mixture is obtained as a solution of the capsule wall prepolymer material;

[0041] (3) Pour the emulsified core material into a 250mL three-neck flask, sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com