A low-cost low-halogen transparent polypropylene film material and its preparation method

A transparent polypropylene and film material technology, applied in the field of film materials, can solve the problems of poor thermal resistance of polypropylene film, affect the transparency of polypropylene film, and easily produce toxic and harmful corrosive gases, etc., so as to achieve the improvement of mechanical properties, Low cost, low impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

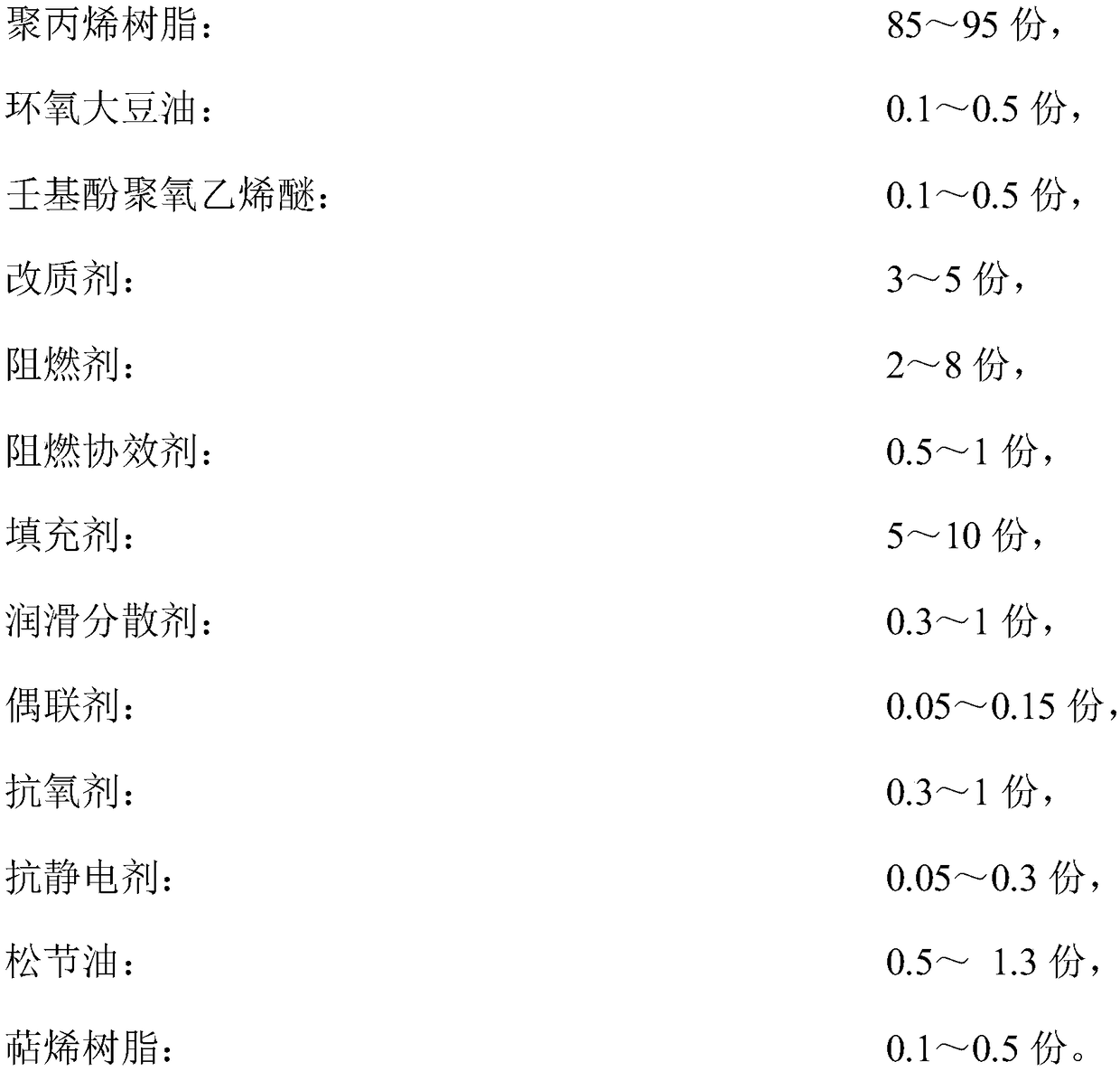

[0028] A low-cost low-halogen transparent polypropylene film material, made of the following raw materials in parts by weight:

[0029]

[0030]

[0031] Among them, the polypropylene resin is a combination of homopolypropylene resin and copolymerized polypropylene resin, and the weight ratio of the two is 2:1; the modifier is polyethylene, maleic anhydride grafted PP, acrylic acid copolymer and transparent nucleating agent The combination of the agent and the weight ratio is 5:5:1:0.1; the flame retardant is the combination of hypophosphite, melamine, brominated phosphate, tetrabromobisphenol A and magnesium hydroxide, the weight ratio is 8:4:2 :1:1; the flame retardant synergist is a combination of pentaerythritol, zinc oxide and antimony trioxide, the weight ratio is 1:2:0.5; the filler is talcum powder, and the filler fineness is 3000 mesh; the lubricating and dispersing agent is pentaerythritol The combination of stearate and polyethylene wax, the weight ratio of th...

Embodiment 2

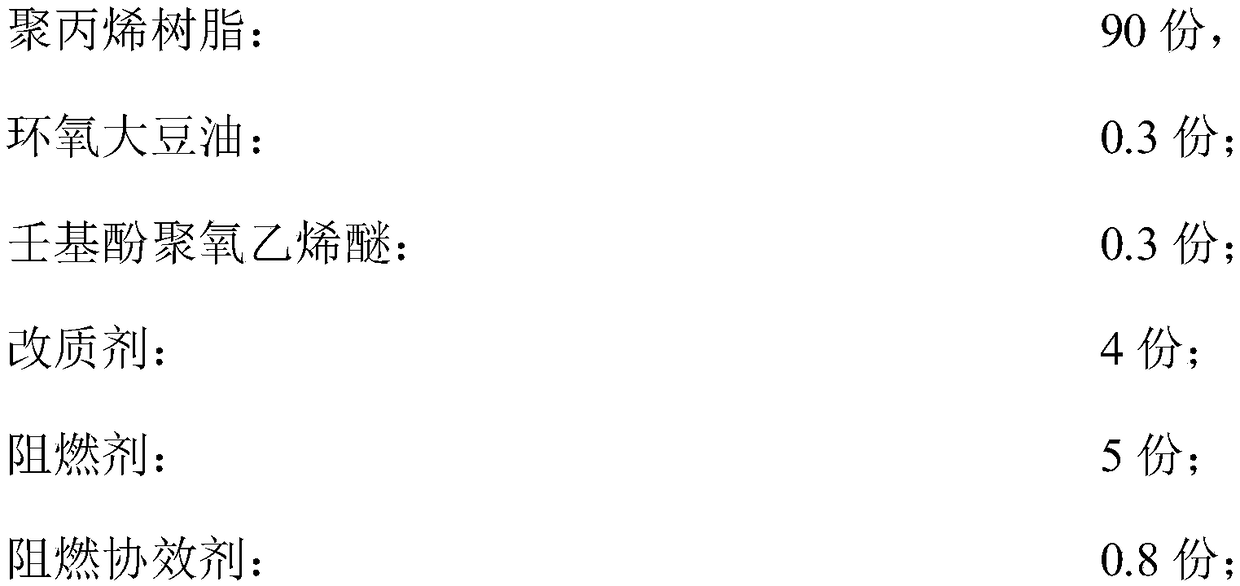

[0037] A low-cost low-halogen transparent polypropylene film material, made of the following raw materials in parts by weight:

[0038]

[0039] Among them, the polypropylene resin is a combination of homopolypropylene resin and copolymerized polypropylene resin, and the weight ratio of the two is 2:1; the modifier is polyethylene, maleic anhydride grafted PP, acrylic acid copolymer and transparent nucleating agent The combination of the agent and the weight ratio is 5:5:1:0.1; the flame retardant is the combination of hypophosphite, melamine, brominated phosphate, tetrabromobisphenol A and magnesium hydroxide, the weight ratio is 8:4:2 :1:1; the flame retardant synergist is a combination of pentaerythritol, zinc oxide and antimony trioxide, the weight ratio is 1:2:0.5; the filler is talcum powder, the filler fineness is 3500 mesh; the lubricating and dispersing agent is pentaerythritol The combination of stearate and polyethylene wax, the weight ratio of the two is 5:1; th...

Embodiment 3

[0045]A low-cost low-halogen transparent polypropylene film material, made of the following raw materials in parts by weight:

[0046]

[0047]

[0048] Among them, the polypropylene resin is a combination of homopolypropylene resin and copolymerized polypropylene resin, and the weight ratio of the two is 2:1; the modifier is polyethylene, maleic anhydride grafted PP, acrylic acid copolymer and transparent nucleating agent The combination of the agent and the weight ratio is 5:5:1:0.1; the flame retardant is the combination of hypophosphite, melamine, brominated phosphate, tetrabromobisphenol A and magnesium hydroxide, the weight ratio is 8:4:2 :1:1; the flame retardant synergist is a combination of pentaerythritol, zinc oxide and antimony trioxide, the weight ratio is 1:2:0.5; the filler is talcum powder, the filler fineness is 3500 mesh; the lubricating and dispersing agent is pentaerythritol The combination of stearate and polyethylene wax, the weight ratio of the two...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com