Housing assembled by light steel space framework structure composite plate module and construction method thereof

A frame structure and composite panel technology, applied in truss structures, residential buildings, building structures, etc., can solve the problems of easy structural errors, flammable safety hazards, shortening the construction period, etc., to avoid structural deformation and Effects of reducing errors, increasing housing utilization, and simplifying construction procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

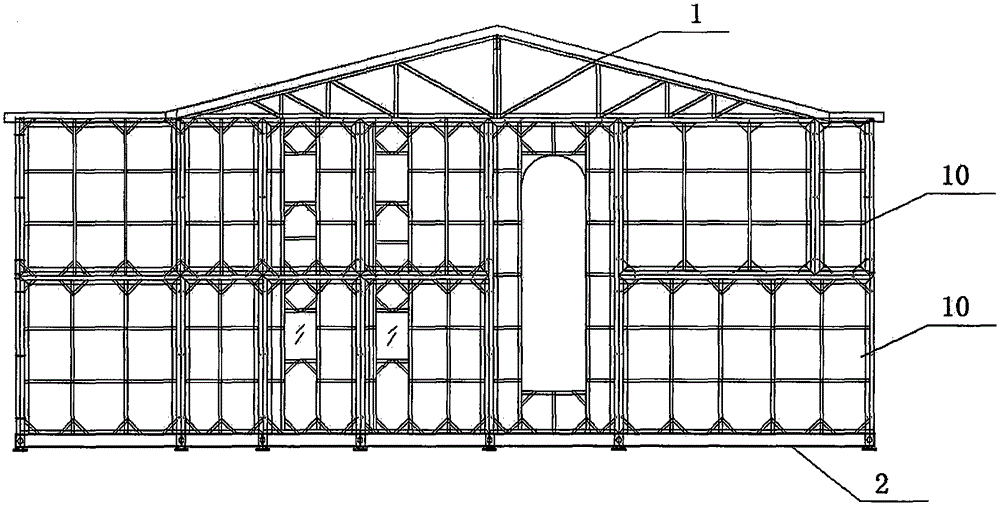

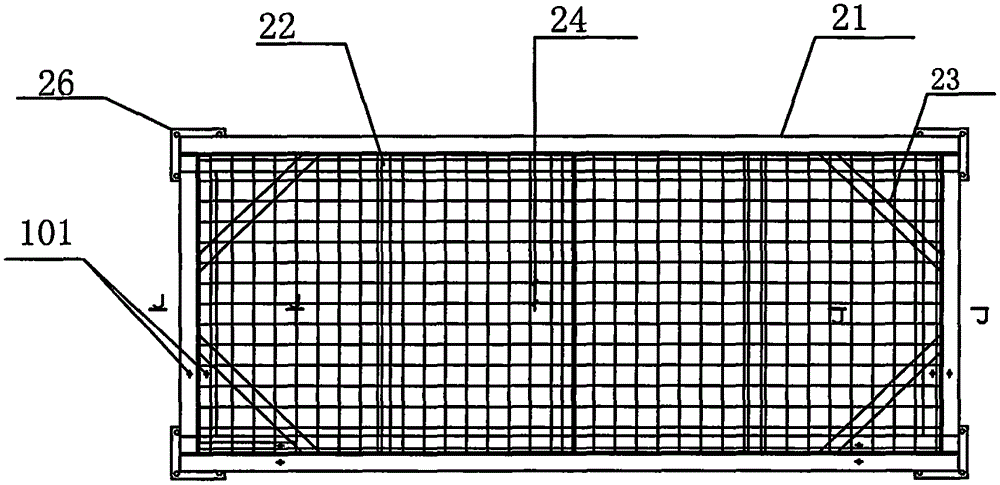

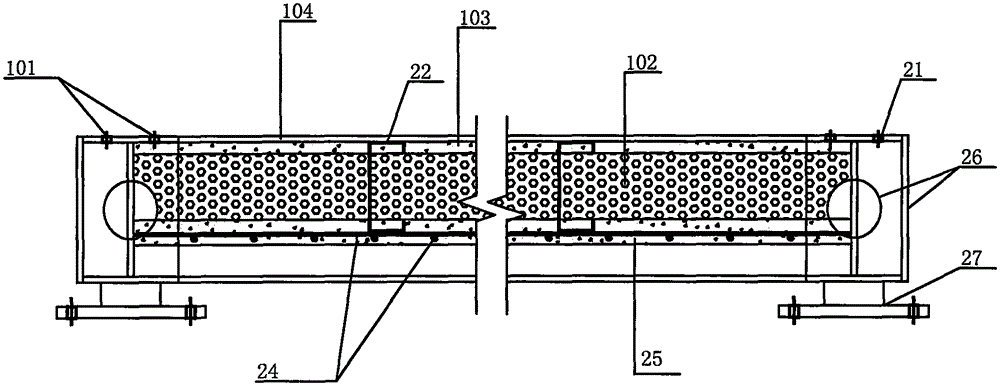

[0064] see Figure 1-30 , a house assembled with three-dimensional light steel frame structure composite panel modules, comprising a three-dimensional light steel frame structure composite ground plate 2, a roof 1, and at least one layer between the three-dimensional light steel frame structure composite ground plate 2 and the roof 1 The room body 10; each layer of the room body 10 includes several composite wall panels 3 with a three-dimensional light steel frame structure with open angles and several composite wall panels 4 with a three-dimensional light steel frame structure with right angles. The vertical side ribs and the top side ribs of the wall panel 3 are made of special-shaped L-shaped steel 100, and the composite wall panels 3 of the three-dimensional light steel frame structure with angled angles and the composite wall panels 4 of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com