Method for directly producing copper alloy from scrap copper

A technology of waste miscellaneous copper and copper alloy, which is applied in the field of metallurgy and can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

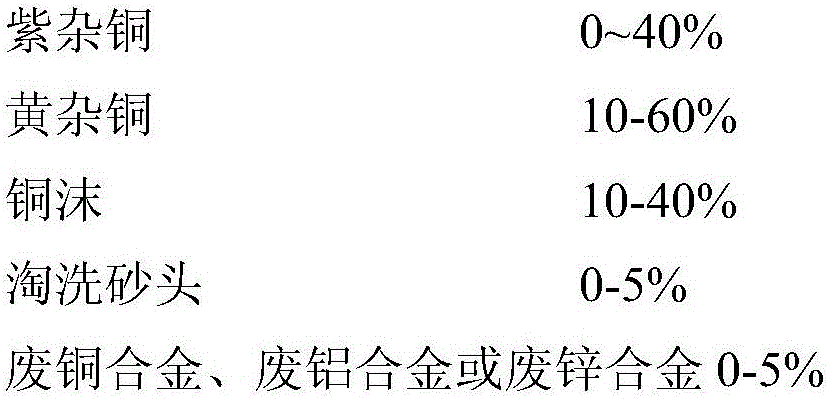

[0071] The ingredients are shown in Table 1.

[0072] Table 1

[0073]

[0074] According to raw materials. The above ratio can be adjusted flexibly.

[0075] The materials are sent to the melting furnace according to the ratio. The melting furnace in this embodiment is a double-body parallel melting furnace. One of the furnaces is used for feeding and melting, and the other furnace is used for refining and composition control. The casting rhythm supplies copper water to the holding furnace. Refining methods include raw material self-reaction refining and slag cleaning refining. According to the analysis of the melt composition, the elements exceeding the standard are subjected to flux removal and refining. The melting temperature is 1010-1080°C. After the chemical composition analysis in front of the furnace is qualified, it is transferred to the holding furnace for heat preservation. The heat preservation temperature is the same as the casting temperature. The ingot o...

Embodiment 2

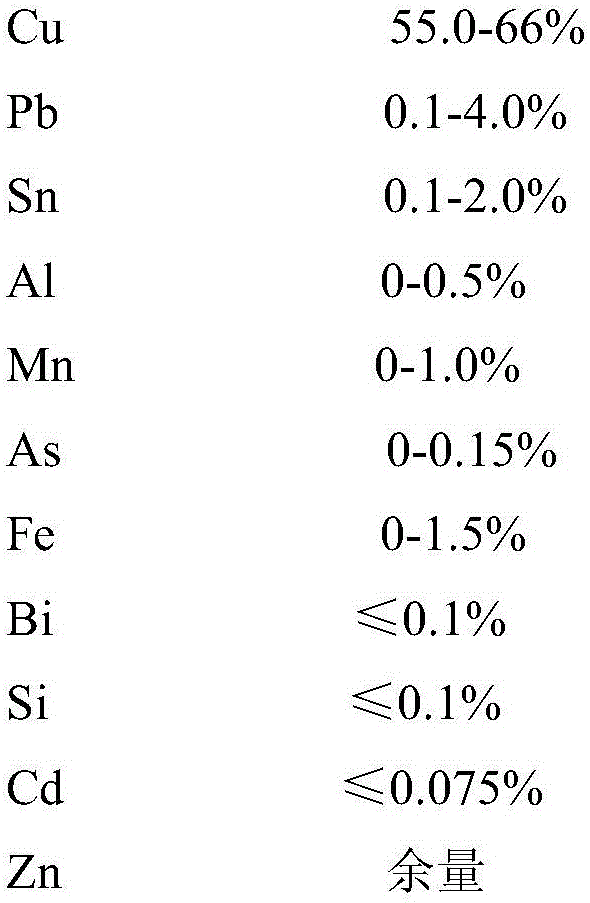

[0088] The recipe is shown in Table 2.

[0089] Table 2

[0090]

[0091] According to the situation of raw materials, the above ratio can be adjusted flexibly.

[0092]After weighing according to the proportion, send it to the melting furnace. The melting temperature is 1000-1080°C; the ingot of Φ86mm is continuously cast horizontally, the casting temperature is 1000-1050°C, the casting speed is 8-18 m / h, and the outlet water temperature is 40-60°C.

[0093] All the other are identical with embodiment 1.

[0094] The ingot passes through the 630-ton extrusion machine production line billet, and the ingot is heated by a stepping and rolling ingot heating furnace, heated by natural gas, and the ingot is heated evenly. The extrusion temperature is 660-740℃, the extrusion speed is 8-18mm / s, the wire is automatically taken up and transposed, the wire billet has no bump defect, and the performance is uniform.

[0095] The extruded wire billet is stretched, annealed, multi-pas...

Embodiment 3

[0103] This embodiment is an example of producing high-precision rods for automatic lathes by direct alloying of scrap copper.

[0104] The recipe is shown in Table 3.

[0105] table 3

[0106]

[0107] The components are sent to the smelting equipment according to the ratio; the smelting equipment adopts smelting furnace, refining furnace, holding furnace group, and the smelting furnace is equipped with a pressing device and a ramming and stirring device. The smelting furnace is used for feeding and smelting, followed by flux refining for slag removal and impurity reduction, and component control. The refining temperature is 1020-1100°C. After the component analysis in front of the furnace is qualified, it is transferred to the holding furnace. The lower part of the holding furnace is equipped with a crystallizer. According to the specifications of the product, the ingots of Φ250mm, Φ195mm, Φ150mm or Φ105 are continuously cast horizontally. The casting temperature is 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com