Imidazolyl Ionic liquids preparing method

A technology of ionic liquid and magnetic ionic liquid, which is applied in the fields of magnetism and organic chemistry of organic materials/organic magnetic materials, can solve the problems of high cost, complex process, poor product effect, etc., and achieve reduced surface tension and simple synthesis process , Improve the performance and scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

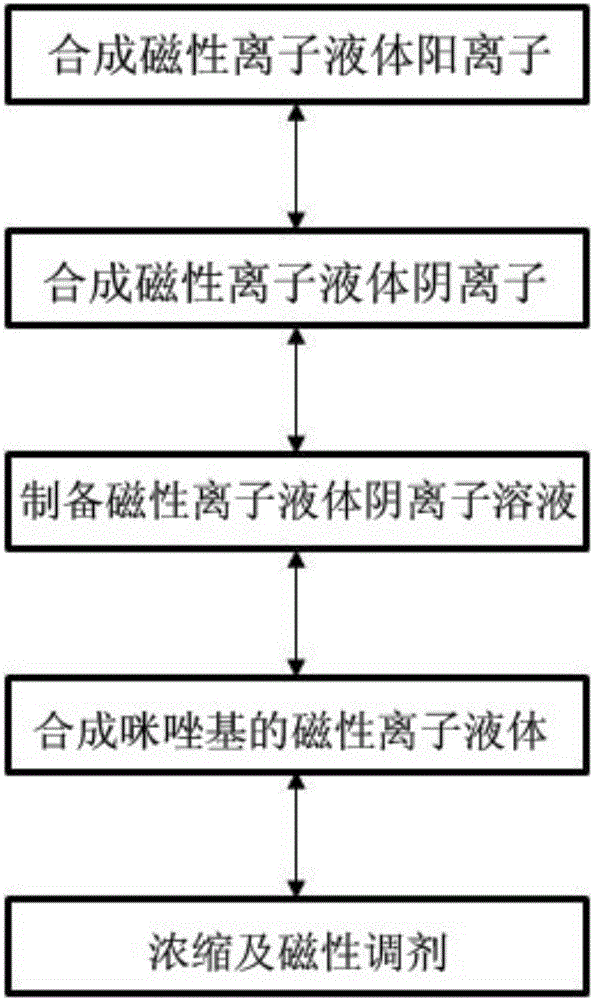

[0031] Such as figure 1 The preparation method of the ionic liquid of a kind of imidazole group shown, comprises the following steps;

[0032] The first step is to synthesize the magnetic ionic liquid cation, dissolve the alkylimidazolium chloride salt and NaOH solution in ethanol at an equimolar ratio, and stir at a uniform speed in one direction at room temperature for 3 hours at a stirring speed of 2000 rpm, and then let it stand And naturally precipitate and filter, and dry and dehydrate the precipitate obtained after filtration in a vacuum environment, and the drying temperature is 30°C, and the cationic reactant can be obtained;

[0033] The second step is to synthesize the magnetic ionic liquid anion. Anhydrous ferric chloride and NaOH are dissolved in water at a molar ratio of 1:3 to form a clear and transparent liquid. Then the two liquids are mixed, and the mixed liquid is mixed. Stir at a constant speed, the stirring speed is 50 rpm, and the mixed solution is fully...

Embodiment 2

[0038] Such as figure 1 The preparation method of the ionic liquid of a kind of imidazole group shown, comprises the following steps;

[0039] The first step is to synthesize the magnetic ionic liquid cation, dissolve the hydroxyimidazolium chloride salt and the potassium hydroxide solution in acetonitrile in an equimolar ratio, and stir at a uniform speed in one direction at room temperature for 1 hour at a stirring speed of 1500 rpm, and then statically Place and naturally precipitate and filter, and dry and dehydrate the filtered precipitate in a vacuum environment, and the drying temperature is 40°C to obtain the cationic reactant;

[0040] The second step is to synthesize a magnetic ionic liquid anion. Manganese bromide and NaOH are dissolved in water at a molar ratio of 1:4 to form a clear and transparent liquid. Then the two liquids are mixed, and the mixed liquid is unidirectionally uniform during mixing. Stir at a stirring speed of 40 revolutions per minute, and full...

Embodiment 3

[0045] Such as figure 1 The preparation method of the ionic liquid of a kind of imidazole group shown, comprises the following steps;

[0046] The first step is to synthesize the magnetic ionic liquid cation, and dissolve the aminoimidazolium chloride salt and NaOH solution in dichloroethane in an equimolar ratio, and stir at a uniform speed in one direction at room temperature for 2 hours, and the stirring speed is 2500 rpm. Then stand still and naturally precipitate and filter, and dry and dehydrate the filtered precipitate in a vacuum environment, and the drying temperature is 50°C to obtain the cationic reactant;

[0047] The second step is to synthesize the magnetic ionic liquid anion, dissolve cobalt chloride 6 hydrate and NaOH in water at a molar ratio of 1:4 to form a clear and transparent liquid, then mix the two liquids, and perform a single Stir at a constant speed, the stirring speed is 10 revolutions per minute, and the mixed solution is fully precipitated, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com