A kind of low-nickel type medium chromium ferritic stainless steel and its manufacturing method

A manufacturing method and medium-chrome ferrochrome technology, which is applied in the field of ferritic stainless steel, can solve the problems of plasticity and impact toughness decrease, poor low-temperature toughness, difficulty in production and pouring, etc., and achieve improved low-temperature impact toughness, good corrosion resistance, and reduced fracture. risky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

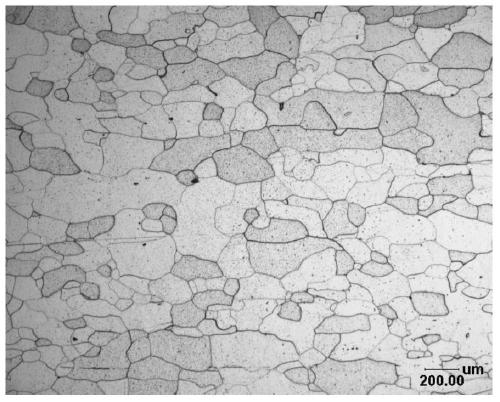

Image

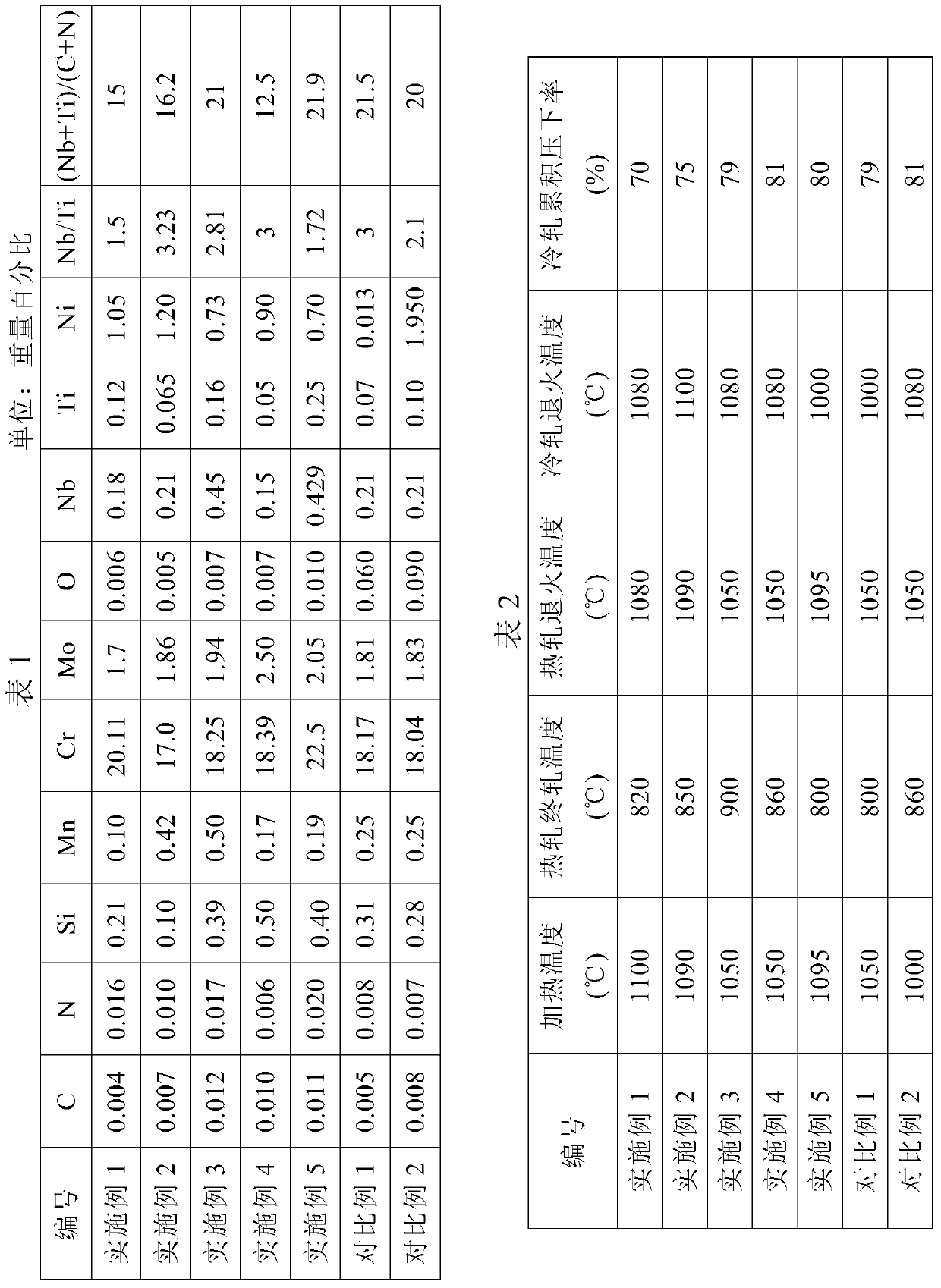

Examples

Embodiment 2

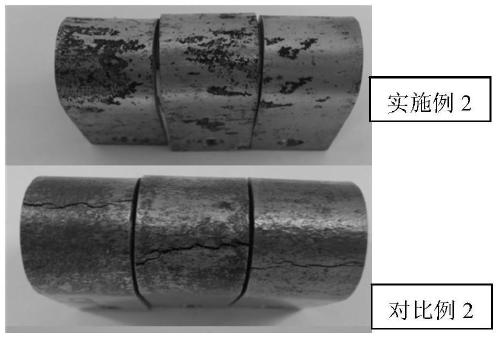

[0049] Embodiment 2 and comparative example 2 have carried out the stress corrosion test of 120h in the boiling magnesium chloride solution, and its result photo is as figure 2 As shown, there was no crack in Example 2 of the present invention, and crack occurred in Comparative Example 2 at 9 hours, and the crack penetrated through the sample after the test. It can be seen that the increase of Ni content is very harmful to the stress corrosion resistance.

[0050] The low-nickel type medium chromium ferritic stainless steel of the present invention is a kind of medium chromium ferritic stainless steel plate containing Ni, Nb, Ti double stabilization, and containing Mo, and its steel plate has excellent low temperature toughness and higher strength .

[0051]

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com