125 ksi high-strength and high-toughness petroleum casing pipe for exploring thickened oil through SAGD method and manufacturing method thereof

A 125ksi, oil casing technology, applied in the field of oil casing and its production, can solve the high temperature performance and anti-collapse performance can not meet the use requirements and other problems, to achieve high anti-collapse performance, improved recovery, high anti-collapse Effect of Shear Deformability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

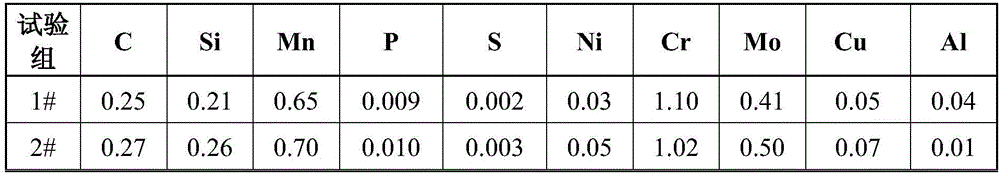

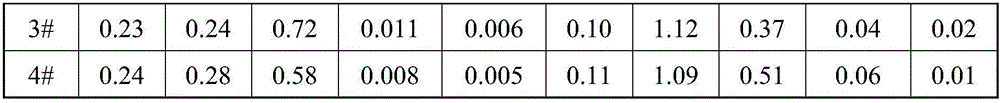

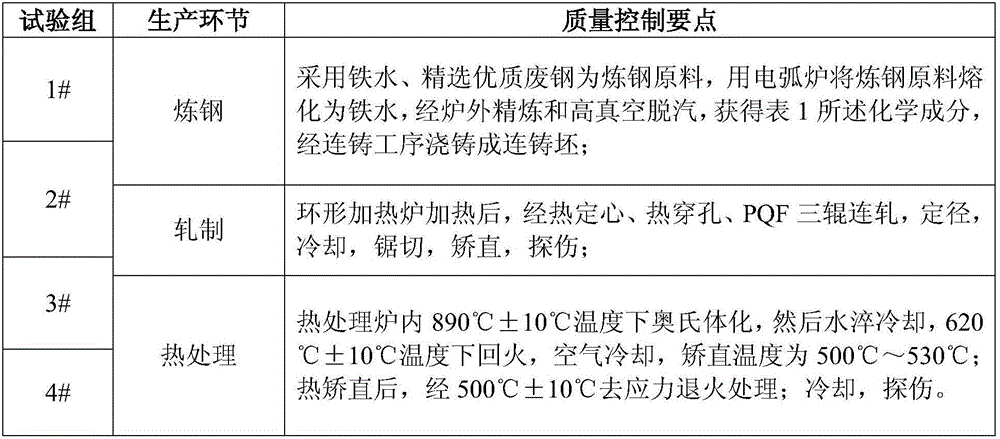

[0023] Oil casing pipe TP125H manufactured according to the composition and method TP-CQ, its chemical composition is shown in Table 1; The production control process is shown in Table 2; The various geometric dimension parameters and various performance parameters of the casing are shown in Table 3, and the casing has a lower outer diameter Out of roundness (0.18-0.20%) and wall thickness unevenness (6-7%), the yield strength at room temperature is 990-1010MPa, and at the test temperature of 350°C, the yield strength at high temperature is 810-850MPa, which is higher than the actual use requirement8 %-13%; the anti-collapse performance of the casing is 61.0-62.0MPa, which is more than 56% higher than the calculated value of API. The transverse full-scale impact value is 101-110J, and the longitudinal full-scale impact value is 159-170J, which makes the casing have excellent collapse resistance and shear deformation resistance.

[0024] The casing has been successfully run i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com