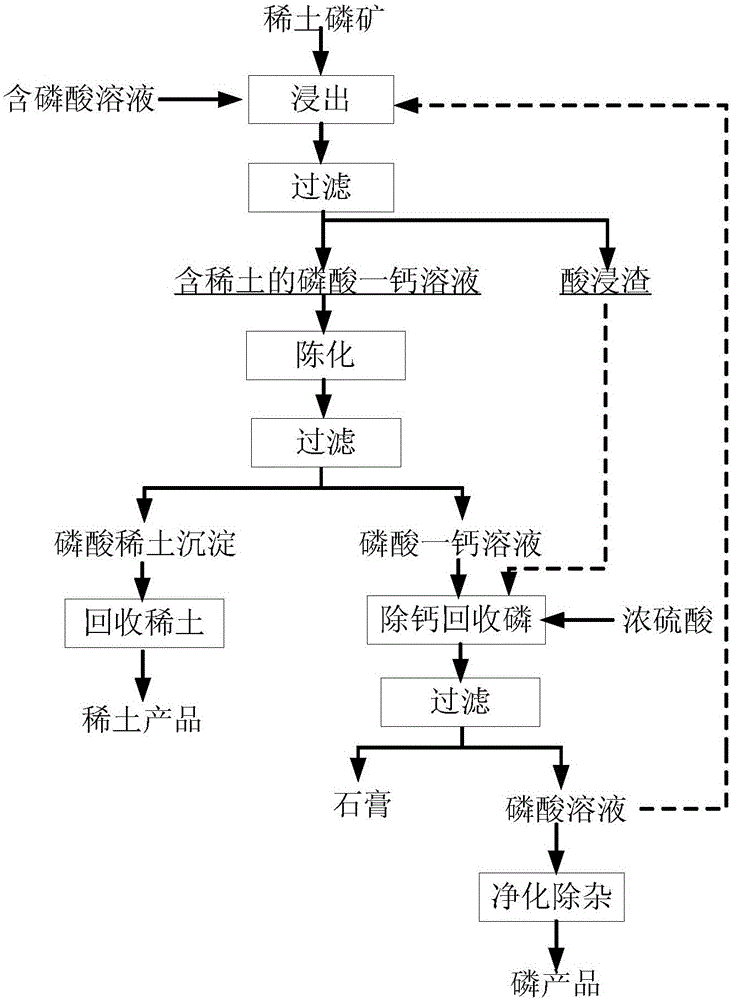

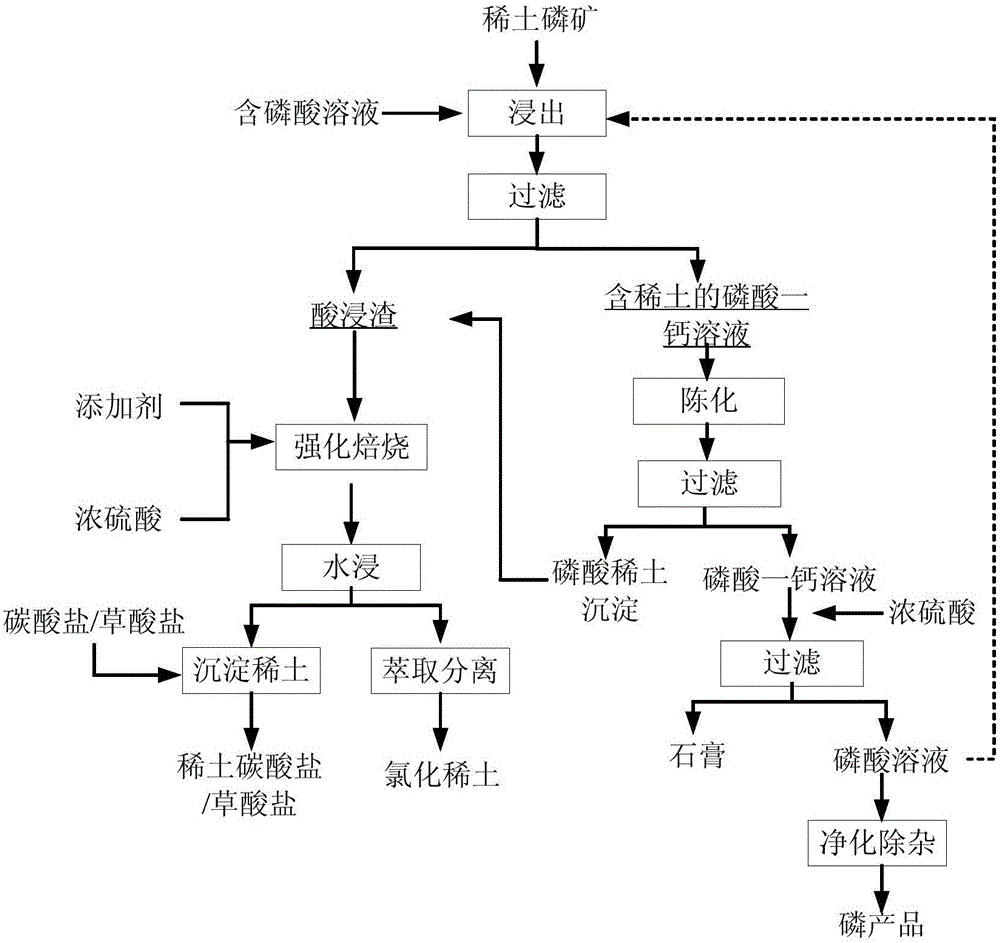

Method for recovering phosphorus and rare earth from rare earth-containing phosphate ore

A technology of rare earth and phosphate rock, which is applied in the direction of chemical instruments and methods, phosphoric acid, phosphorus oxyacid, etc., can solve the problems of low recovery efficiency of phosphorus and rare earth elements, and achieve the purpose of improving the separation efficiency of rare earth, separating rare earth at low cost, reducing the The effect of miscellaneous burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Using 1000g of phosphate rock with a rare earth content of 0.05wt% as raw material, use a phosphoric acid solution with a mass concentration of 15% to leach the rare earth phosphate rock, control the liquid-solid ratio of the system at 10:1, react at 10°C for 1 hour, filter Finally, monocalcium phosphate solution containing rare earth and acid leaching residue are obtained.

[0061] Put the rare earth-containing monocalcium phosphate solution at 60°C for aging treatment for 24 hours, so that the rare earth elements are precipitated in the form of rare earth phosphate precipitates, and the monocalcium phosphate solution and 0.71g of rare earth phosphate precipitates are obtained through solid-liquid separation.

[0062] After testing, the leaching rate of impurity Fe in phosphate rock was 3.5%, the leaching rate of impurity Al was 2.5%, and the leaching rate of phosphorus element was 95.3%; the content of rare earth in rare earth phosphate precipitation was 57.1%, and the...

Embodiment 2

[0064] Using 1000g of phosphate rock with a rare earth content of 0.2wt% as raw material, use a phosphoric acid solution with a mass concentration of 20% to leach the rare earth phosphate rock, control the liquid-solid ratio of the system at 6:1, react at 20°C for 6 hours, and filter Finally, monocalcium phosphate solution containing rare earth and acid leaching residue are obtained.

[0065] Put the rare earth-containing monocalcium phosphate solution at 60°C for aging treatment for 1 hour, so that the rare earth element is separated from the monocalcium phosphate solution in the form of rare earth phosphate precipitation, and thus through solid-liquid separation, a monocalcium phosphate solution and 3.30 g Precipitation of rare earth phosphate.

[0066] After testing, the leaching rate of Fe in phosphate rock was 4.1%, that of Al was 3.1%, and that of phosphorus element was 96.8%. The content of rare earth in rare earth phosphate precipitation was 52.1%, and the recovery rat...

Embodiment 3

[0068] Using 1000g of phosphate rock with a rare earth content of 0.2wt% as raw material, use a phosphoric acid solution with a mass concentration of 20% to leach the rare earth phosphate rock, control the liquid-solid ratio of the system at 6:1, react at 20°C for 6 hours, and filter Finally, monocalcium phosphate solution containing rare earth and acid leaching residue are obtained.

[0069] Place the rare earth-containing monocalcium phosphate solution at 80°C for aging treatment for 1 hour, so that the rare earth element is separated from the monocalcium phosphate solution in the form of rare earth phosphate precipitation, and thus through solid-liquid separation, a monocalcium phosphate solution and 3.40 g Precipitation of rare earth phosphate.

[0070] After testing, the leaching rate of Fe in phosphate rock was 4.1%, that of Al was 3.1%, and that of phosphorus element was 96.6%. The content of rare earth in rare earth phosphate precipitation was 53.8%, and the recovery r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com