Reversible physical crosslinking agent and preparation method thereof

A technology of physical cross-linking agent and surfactant, applied in the direction of chemical instruments and methods, drilling compositions, etc. Few reports, complex synthesis process and other issues, to achieve the effect of low price, few types, and simple synthesis process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1: Preparation of reversible physical crosslinking agent.

[0041] Add a certain amount of deionized water into the beaker, heat to 40°C, weigh 20% sodium dodecylsulfonate and add it to the above beaker, stir mechanically for 5min at a stirring rate of 400rad / min, weigh 20% sodium dodecylsulfonate Methanol was added into the above beaker, and mechanically stirred for 20 minutes to prepare a colorless transparent liquid, which was a reversible physical crosslinking agent.

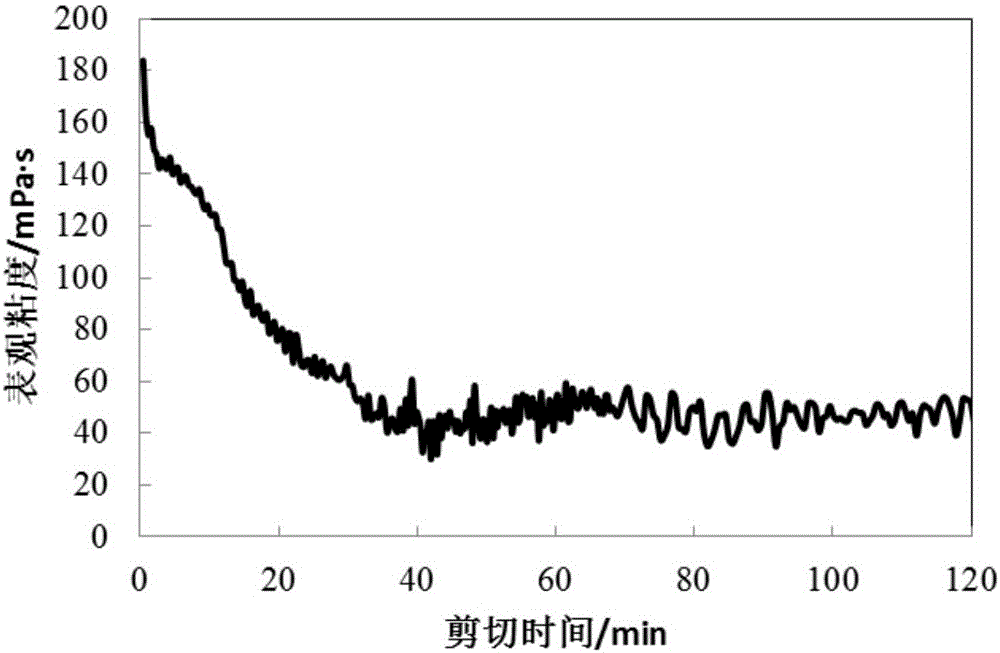

[0042] The rheological curve (120°C) of the fracturing fluid formulated with 0.2% of the above-mentioned reversible physical cross-linking agent and 0.5% polymer thickener is as follows figure 1 shown.

[0043] 0.2% of the above reversible physical cross-linking agent with 0.5% of polymer thickener (sodium acrylate, hydrophobically associating monomer, sodium p-styrenesulfonate, 2-acrylamide-2-methylpropanesulfonic acid and acrylamide A copolymer of five monomers with a molecular weight of 5...

Embodiment 2

[0047] Example 2: Preparation of reversible physical crosslinking agent.

[0048] Add a certain amount of deionized water into the beaker, heat to 50°C, weigh 25% of sodium dodecylbenzenesulfonate and add it to the above beaker, stir mechanically for 8min at a stirring rate of 500rad / min, weigh 25% Propanol was added into the above beaker and mechanically stirred for 25 minutes to prepare a colorless transparent liquid, which was a reversible physical crosslinking agent.

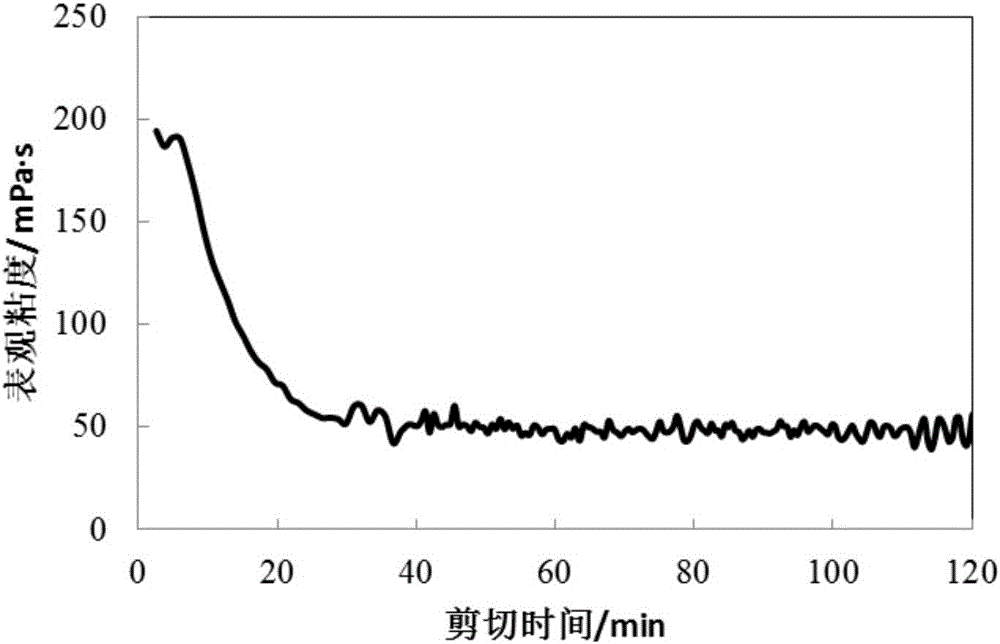

[0049] The rheological curve (140°C) of the fracturing fluid formulated with 0.25% of the above reversible physical cross-linking agent and 0.55% polymer thickener is as follows figure 2 shown.

[0050] 0.25% of the above-mentioned reversible physical crosslinking agent and 0.55% of polymer thickener (sodium acrylate, hydrophobic association monomer, sodium p-styrenesulfonate, 2-acrylamide-2-methylpropanesulfonic acid, acrylamide A copolymer of five monomers with a molecular weight of 5 million) produces ...

Embodiment 3

[0053] Example 3: Preparation of reversible physical crosslinking agent.

[0054] Add a certain amount of deionized water into the beaker, heat it to 60°C, weigh 40% sodium lauryl polyoxyethylene ether sulfate and add it to the above beaker, stir mechanically for 10min at a stirring rate of 600rad / min, weigh Add 40% butanol into the above beaker, and mechanically stir for 30 minutes to prepare a colorless transparent liquid, which is a reversible physical crosslinking agent.

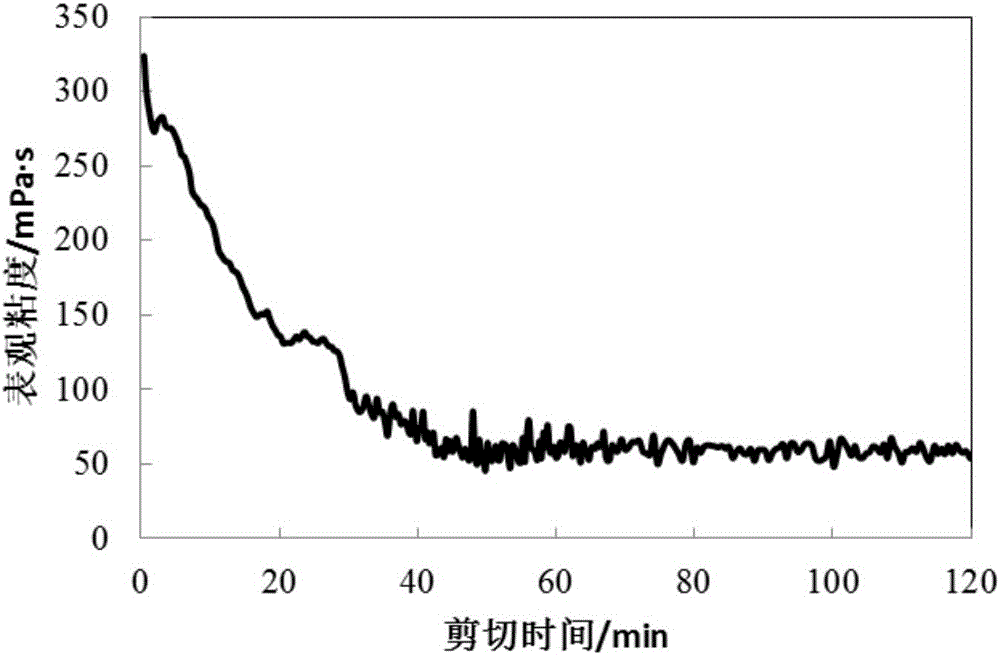

[0055] The rheological curve (160°C) of the fracturing fluid formulated with 0.3% of the above reversible physical cross-linking agent and 0.6% polymer thickener is as follows image 3 shown.

[0056] 0.3% of the above reversible physical crosslinker with 0.6% of polymer thickeners (sodium acrylate, hydrophobically associating monomer, sodium p-styrenesulfonate, 2-acrylamide-2-methylpropanesulfonic acid and acrylamide A copolymer of five monomers with a molecular weight of 10 million) produces physical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com