Coal pitch suitable for paving heavy traffic roads and preparation method thereof

A technology of coal tar pitch and heavy traffic, which is applied in the direction of building components, building insulation materials, buildings, etc., can solve the problems of no bitumen data effects, etc., and achieve the effects of ensuring production safety, short production cycle and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

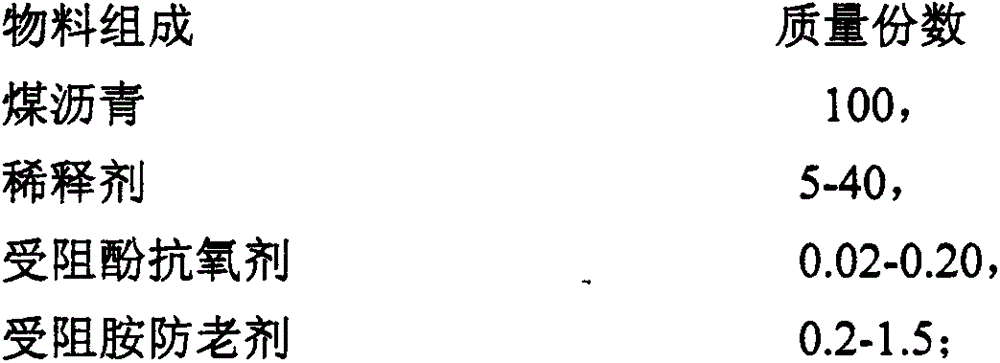

Method used

Image

Examples

Embodiment 1

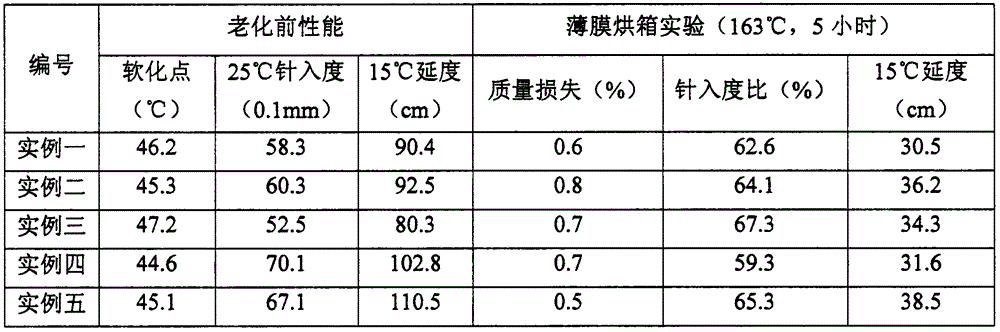

[0029] Take 100g of coal tar pitch and add it to the reaction kettle, raise the temperature to 115°C to completely melt the coal tar pitch, add 40g of aromatic oil as a diluent, and stir at a speed of 700rpm for 1 hour; keep the temperature and speed constant, add 0.04g of hindered phenolic Oxygen 1076, add 0.8g hindered amine anti-aging agent DQC after 0.5 hours, continue to stir for 1.5 hours, cool and discharge to obtain the aging-resistant coal tar pitch product.

[0030] The softening point, penetration, ductility and aging resistance are tested according to the methods stipulated in "GBT 5180-2010 Petroleum Asphalt for Heavy Traffic Roads" and "JTG F40-2004 Technical Specifications for Construction of Highway Asphalt Pavement".

Embodiment 2

[0032] The implementation steps are the same as in Embodiment 1. The difference is: use residual oil of equal quality to replace aromatic oil, and hindered phenol antioxidant 1520 to replace 1076.

[0033] The performance evaluation method is the same as in Example 1.

Embodiment 3

[0035] The implementation steps are the same as in Embodiment 1. The difference is: 0.10 g of hindered phenol antioxidant 1520 replaces 0.03 g of hindered phenol antioxidant 1076.

[0036] The performance evaluation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com