Method for preparing hydrazinobenzene in continuous micro-channel reactor

A micro-channel reactor and channel reactor technology, applied in the field of fine chemicals, can solve the problems of long process time of phenylhydrazine, difficult to control the safety of the reaction process, low yield, etc. Warm explosion hazard, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

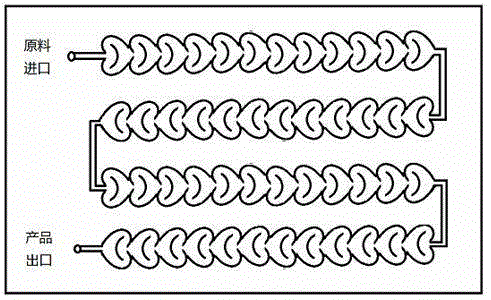

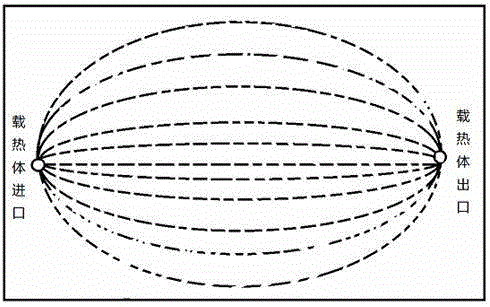

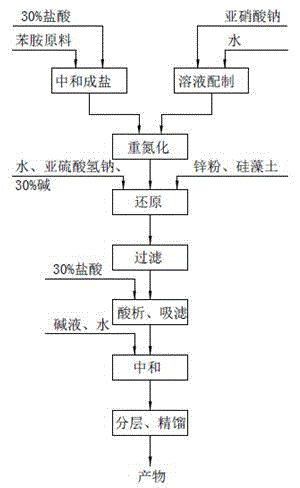

[0030] Device: Coring heart-shaped microchannel reactor, 6 plates are selected for the reaction module, and the raw material feeding method is referred to image 3 Confirm that the heat exchange medium is heat transfer oil.

[0031] Aniline hydrochloride configuration: At room temperature, add 310 ml of 30% hydrochloric acid (3.0 mol) and 200 mL of water into a 1000 mL three-necked flask, add 93 g (1.0 mol) of aniline dropwise within 30 minutes, and stir for 30 minutes after the addition , Formulated into aniline hydrochloride.

[0032] Sodium nitrite solution configuration: 64 g (1.0 mol) sodium nitrite and 300 mL of water are used to make a 40% sodium nitrite solution.

[0033] Diazotization: Use a circulator cooler to cool the reactor. Set the temperature of the reactor to 5°C. After the temperature stabilizes, pump the aniline hydrochloride solution into the reactor through a metering pump with a flow rate of 20 mL / min ,Pour 40% sodium nitrite solution into the reactor through a...

Embodiment 2

[0038] Aniline hydrochloride configuration: at room temperature, add 237 ml 30% hydrochloric acid (2.3 mol) and 200 mL water into a 1000 mL three-necked flask, add 93 g (1.0 mol) of aniline dropwise within 30 minutes, and stir for 30 minutes after the addition , Formulated into aniline hydrochloride.

[0039] Sodium nitrite solution configuration: 64g (1.0 mol) of sodium nitrite and 300 mL of water are mixed into a 40% sodium nitrite solution.

[0040] Diazotization: Use a circulator cooler to cool the reactor. Set the temperature of the reactor to 0°C. After the temperature stabilizes, pump the aniline hydrochloride solution into the reactor through a metering pump, with a flow rate of 20 mL / min , The 40% sodium nitrite solution was pumped into the reactor through a metering pump, the flow rate was controlled at 44 mL / min, the materials were reacted in the microchannel reactor, the reaction residence time was 28 s, the reaction pressure was 0.2 MPa, and the diazonium liquid The r...

Embodiment 3

[0045] Aniline hydrochloride configuration: at room temperature, add 330 ml 30% hydrochloric acid (3.2 mol) and 200 mL water into a 1000 mL three-necked flask, add 93 g (1.0 mol) of aniline dropwise within 30 minutes, and stir for 30 minutes after the addition , Formulated into aniline hydrochloride.

[0046] Sodium nitrite solution configuration: 64 g (1.0mol) sodium nitrite and 300 mL of water are mixed into a 40% sodium nitrite solution.

[0047] Diazotization: Use a circulator cooler to cool the reactor. Set the temperature of the reactor to 10°C. After the temperature stabilizes, pump the aniline hydrochloride solution into the reactor through a metering pump, with a flow rate of 20 mL / min ,Pour 40% sodium nitrite solution into the reactor through a metering pump. The flow rate is controlled at 48 mL / min. The materials react in the microchannel reactor. The reaction residence time is 26 s, the reaction pressure is 0.2 MPa, and the diazonium liquid The reactor flows continuous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com