Preparation method and application of graphene-coated nano dysprosium oxide

A nano-dysprosium oxide and graphene-coated technology, applied in chemical instruments and methods, rare earth metal oxides/hydroxides, inorganic chemistry, etc., can solve the problem of reducing inter-grain connectivity, uneven distribution, and poor dispersion and other problems, to achieve the effect of improving superconducting performance, increasing reactivity, and inhibiting agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

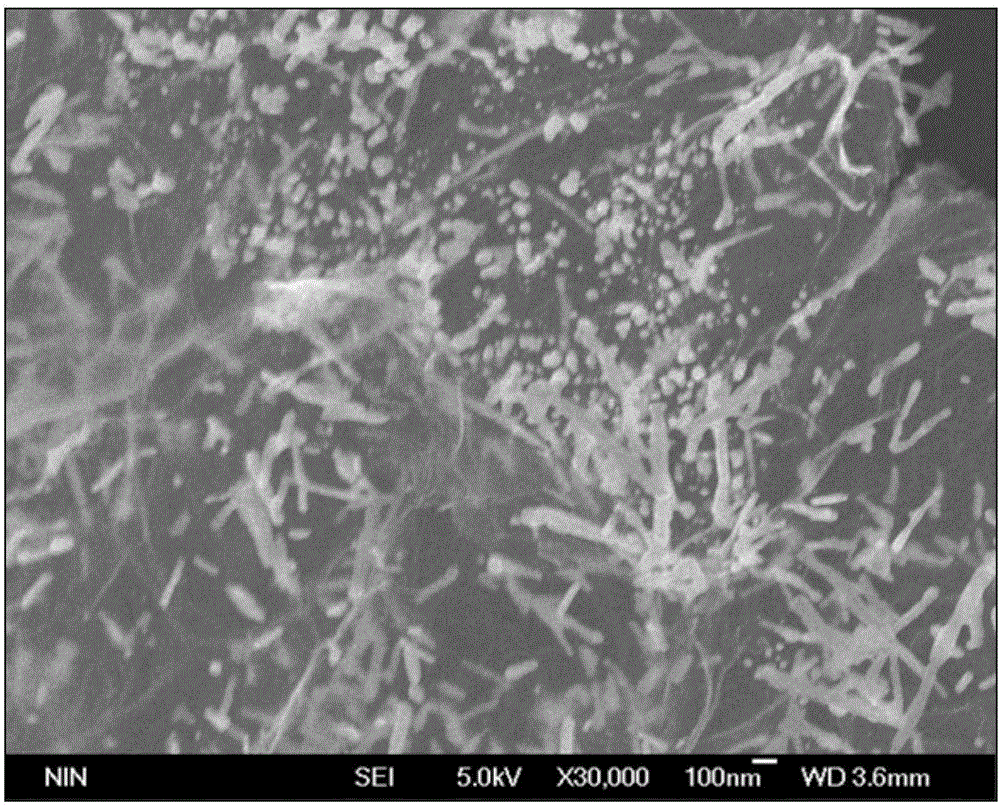

Image

Examples

Embodiment 1

[0026] The method for preparing graphene-coated nano-dysprosium oxide in this embodiment comprises the following steps:

[0027] Step 1. Dissolve dysprosium acetate in a mixed solvent of ethanol and propionic acid to obtain a dysprosium acetate solution, place the dysprosium acetate solution in a pyrolysis reactor, and first dry it at a temperature of 120°C. Then, under a moist oxygen atmosphere, continue to heat up to 500°C with a heating rate of 2°C / min to obtain dysprosium oxide nanoparticles; the volume ratio of ethanol and propionic acid in the mixed solvent is 1:1; the moist oxygen The volume percentage of oxygen in the atmosphere is 96.5%, and the balance is water vapor;

[0028] Step 2, dissolving dysprosium nitrate in an aqueous solution of tert-butylamine, and then placing it in a hydrothermal reaction kettle to obtain dysprosium oxide nanocolumns after hydrothermal reaction; in the aqueous solution of tert-butylamine, tert-butylamine and The volume ratio of water i...

Embodiment 2

[0036] The method for preparing graphene-coated nano-dysprosium oxide in this embodiment comprises the following steps:

[0037] Step 1. Dissolve dysprosium acetate in a mixed solvent of ethanol and propionic acid to obtain a dysprosium acetate solution, place the dysprosium acetate solution in a pyrolysis reactor, and first dry it at a temperature of 120°C. Then, under a moist oxygen atmosphere, continue to heat up to 500°C with a heating rate of 5°C / min to obtain dysprosium oxide nanoparticles; the volume ratio of ethanol and propionic acid in the mixed solvent is 1:1; the moist oxygen The volume percentage of oxygen in the atmosphere is 94%, and the balance is water vapor;

[0038] Step 2, dissolving dysprosium nitrate in the aqueous solution of aminoacetic acid, and then placing it in a hydrothermal reaction kettle to obtain dysprosium oxide nanocolumns after the hydrothermal reaction; the volume ratio of aminoacetic acid to water in the aqueous solution of aminoacetic aci...

Embodiment 3

[0045] The method for preparing graphene-coated nano-dysprosium oxide in this embodiment comprises the following steps:

[0046] Step 1. Dissolve dysprosium acetate in a mixed solvent of ethanol and propionic acid to obtain a dysprosium acetate solution, place the dysprosium acetate solution in a pyrolysis reactor, and first dry it at a temperature of 120°C. Then, under a moist oxygen atmosphere, continue to heat up to 500°C with a heating rate of 1°C / min to obtain dysprosium oxide nanoparticles; the volume ratio of ethanol and propionic acid in the mixed solvent is 1:1; the moist oxygen The volume percentage of oxygen in the atmosphere is 99.4%, and the balance is water vapor;

[0047] Step 2, dissolving dysprosium nitrate in an aqueous solution of tert-butylamine, and then placing it in a hydrothermal reaction kettle to obtain dysprosium oxide nanocolumns after hydrothermal reaction; in the aqueous solution of tert-butylamine, tert-butylamine and The volume ratio of water i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com