Synthetic method of material with palladium particles loaded on three-dimensional macroporous molybdenum dioxide

A three-dimensional macroporous, molybdenum dioxide technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve problems such as plastic deformation and performance degradation, and achieve current Increased density, improved catalytic performance, and shorter time-consuming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

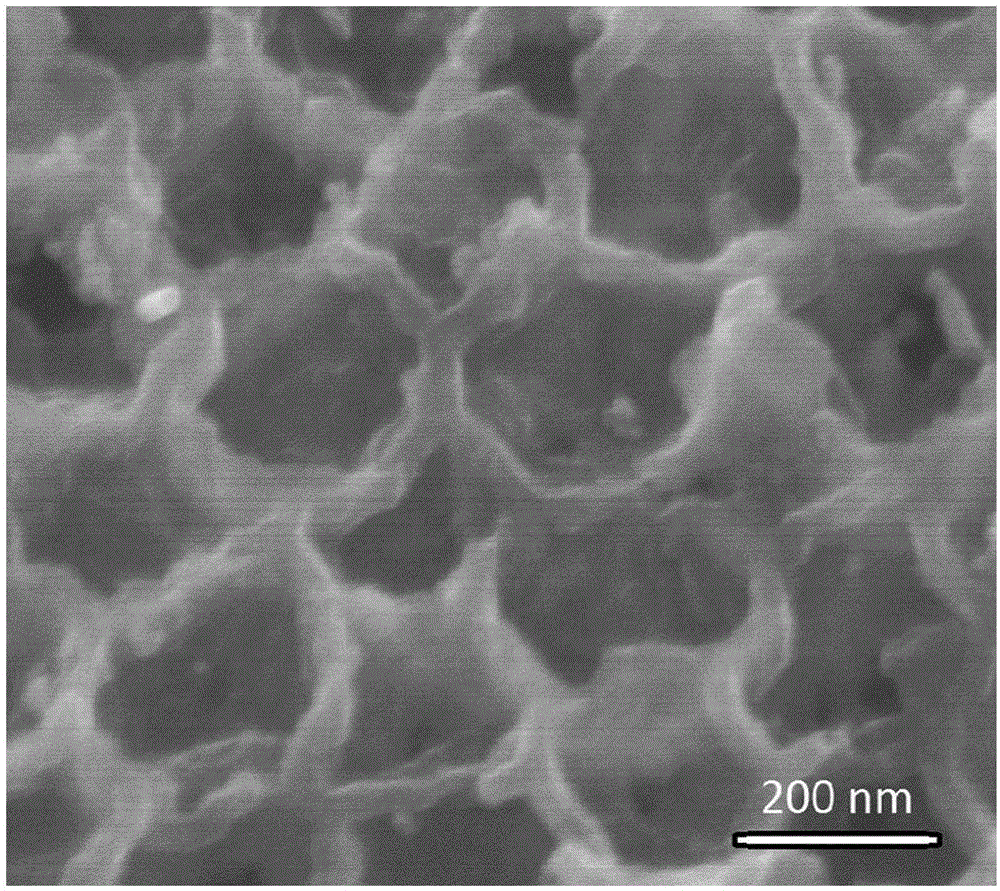

[0022] Take 2g of the template and put it into 10ml of 0.05M MoCl 5 Put the beaker into a 50°C incubator, seal the beaker to prevent the volatilization of water, and oxidize the solution in about two days, filter it several times and dry it to obtain a blue solid. Put this solid in a crucible and put it into a heating furnace that can pass through a protective atmosphere, heat treatment for 2 hours from 20°C to 650°C under the protection of flowing argon atmosphere, and the heating rate is 5°C / min, and then cool with the furnace to obtain Three-dimensional macroporous MoO with a pore size of 200 nm 2 .

[0023] Obtained MoO 2 Put 20 mg into 20 ml of water, hydrochloric acid, stannous chloride (mass ratio is 20:1:0.1) mixed suspension, hydrochloric acid is 1mol / L hydrogen chloride aqueous solution, stir with a magnetic stirrer for 30 minutes, centrifuge to get the precipitate thing. Put the precipitate into PdCl 2 Solution (10mL water, 0.5g PdCl 2 ), stirred with a magne...

Embodiment 2

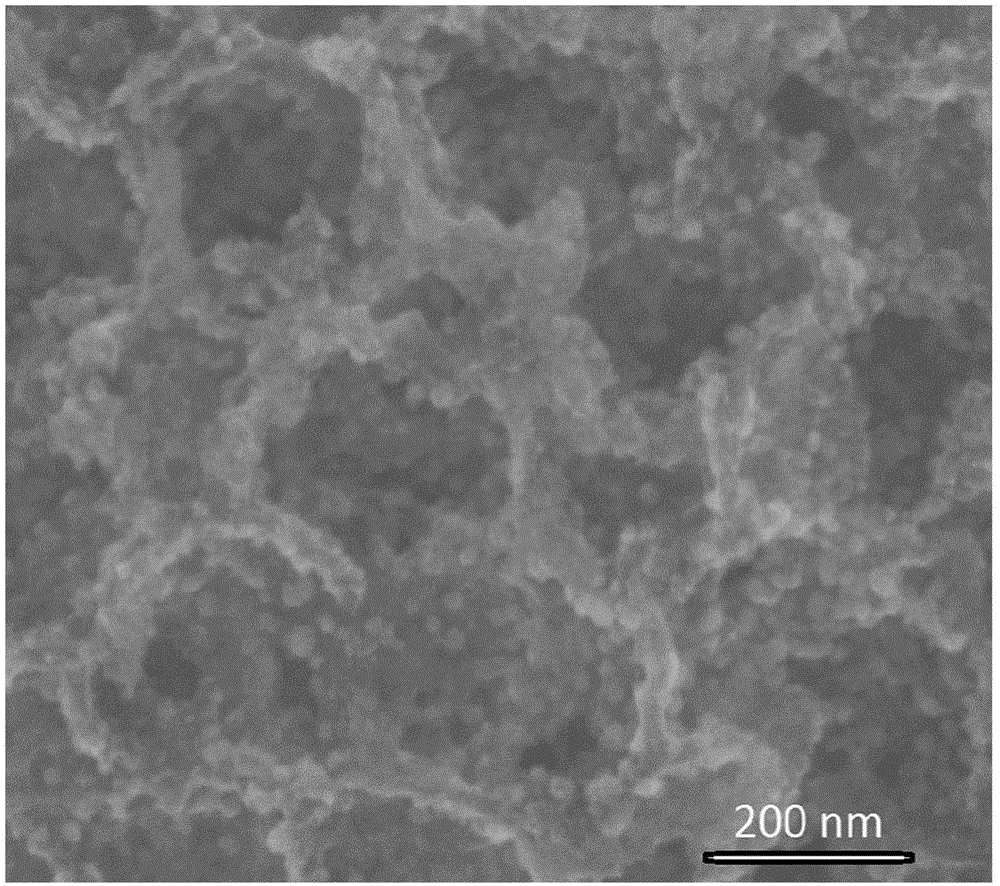

[0025]Take 2g of the template and put it into 10ml of 0.05M MoCl 5 Put the beaker into a 50°C incubator, seal the beaker to prevent the volatilization of water, and oxidize the solution in about two days, filter it several times and dry it to obtain a blue solid. Put this solid in a crucible and put it into a heating furnace that can pass through a protective atmosphere, and heat it from 25°C to 640°C for 1.5 hours under the protection of a flowing argon atmosphere, and the heating rate is about 8°C / min. After cooling in the furnace, a three-dimensional macroporous MoO with a pore size of 350 nm was obtained. 2 .

[0026] Obtained MoO 2 Put 20 mg into 20 ml of water, hydrochloric acid, and a mixed suspension with a submass ratio of chloride (20:1:0.1), the hydrochloric acid is 3mol / L hydrogen chloride aqueous solution, and the precipitate is put into PdCl 2 Solution (10mL water, 0.5g PdCl 2 ), stirred with a magnetic stirrer for 30 minutes, centrifuged to take the precipi...

Embodiment 3

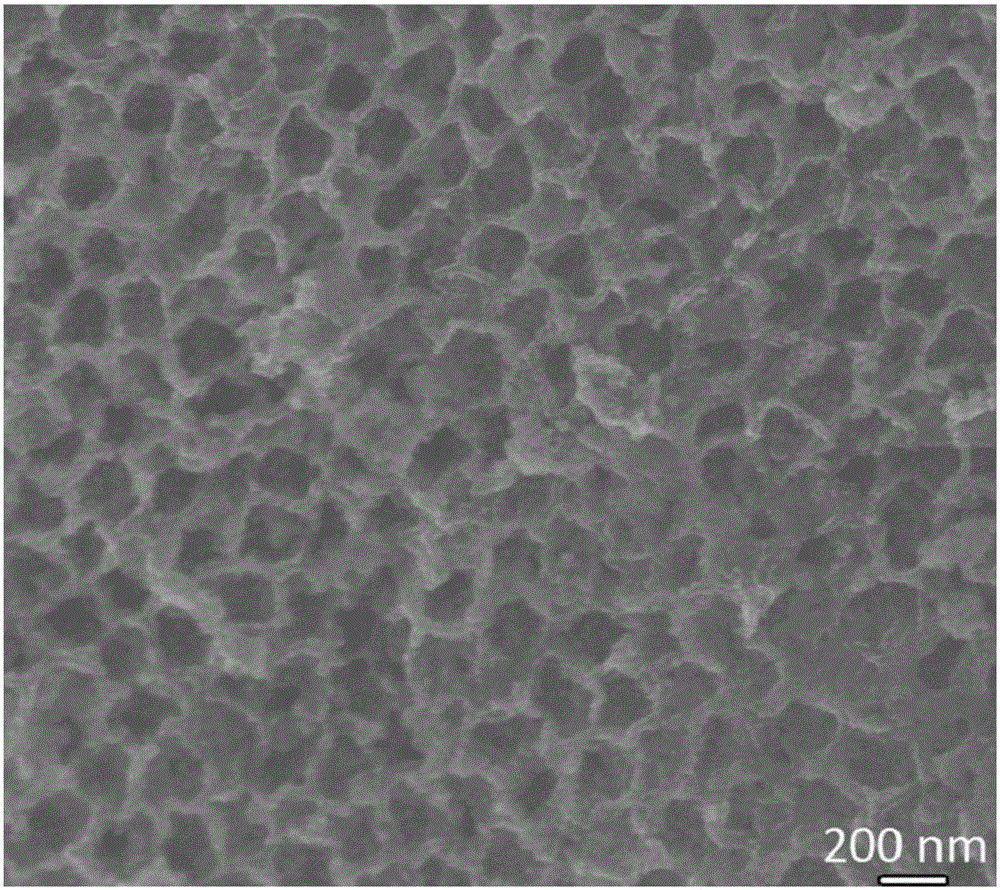

[0028] Take 2g of the template and put it into 10ml of 0.05M MoCl 5 Put the beaker into a 50°C incubator, seal the beaker to prevent the volatilization of water, and oxidize the solution in about two days, filter it several times and dry it to obtain a blue solid. Put this solid in a crucible and put it into a heating furnace that can pass through a protective atmosphere, and heat it from 22°C to 645°C for 2 hours under the protection of a flowing argon atmosphere, and the heating rate is about 8°C / min. After cooling in the furnace, a three-dimensional macroporous MoO with a pore size of 400 nm was obtained. 2 .

[0029] Obtained MoO 2 Put 20 mg into 20 ml of water, hydrochloric acid, stannous chloride (mass ratio is 20:1:0.1) mixed suspension, hydrochloric acid is 5mol / L hydrogen chloride aqueous solution, stir with a magnetic stirrer for 30 minutes, centrifuge to get the precipitate things. Put the precipitate into PdCl 2 Solution (10mL water, 0.5g PdCl 2 ), stirred w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com