Processing technology of Skip Via laser drilling

A technology of laser drilling and processing technology, which is applied to the formation of electrical connections of printed components, electrical components, and printed circuit manufacturing. It can solve problems such as residual glue, improve the quality of the hole wall, ensure the quality of the hole wall, and repair the hole wall. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A processing technology of Skip Via laser drilling, comprising the following steps:

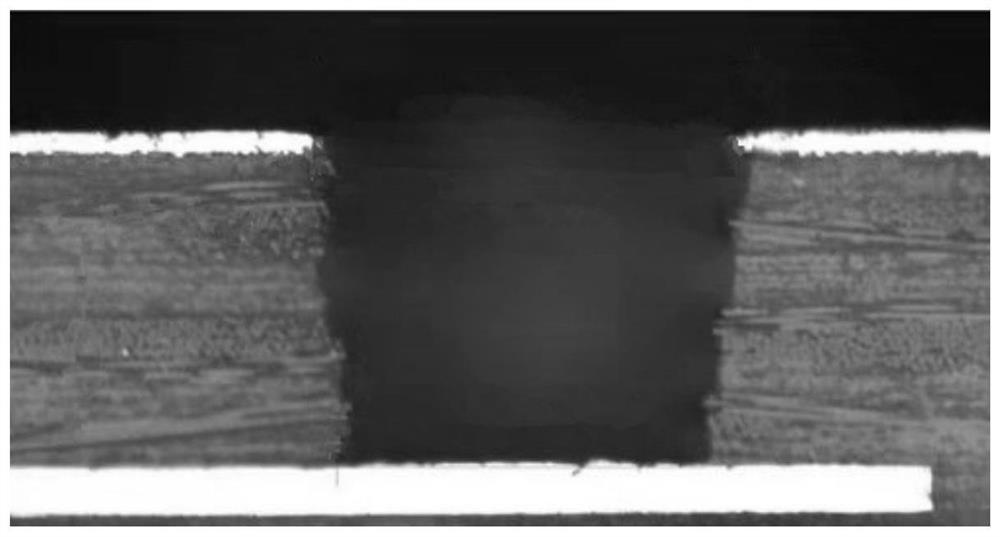

[0048] S1. First design the position of the blind hole with a laser on the laminated substrate. The window opening data is designed to be 8 mil larger than the D of the laser drilled hole (blind hole), and then open the window on the copper skin at the position where the laser blind hole is drilled. Then the copper skin is etched away by exposure, development and etching, the measured size meets the requirements, and the window opening of the Comfort mask is completed;

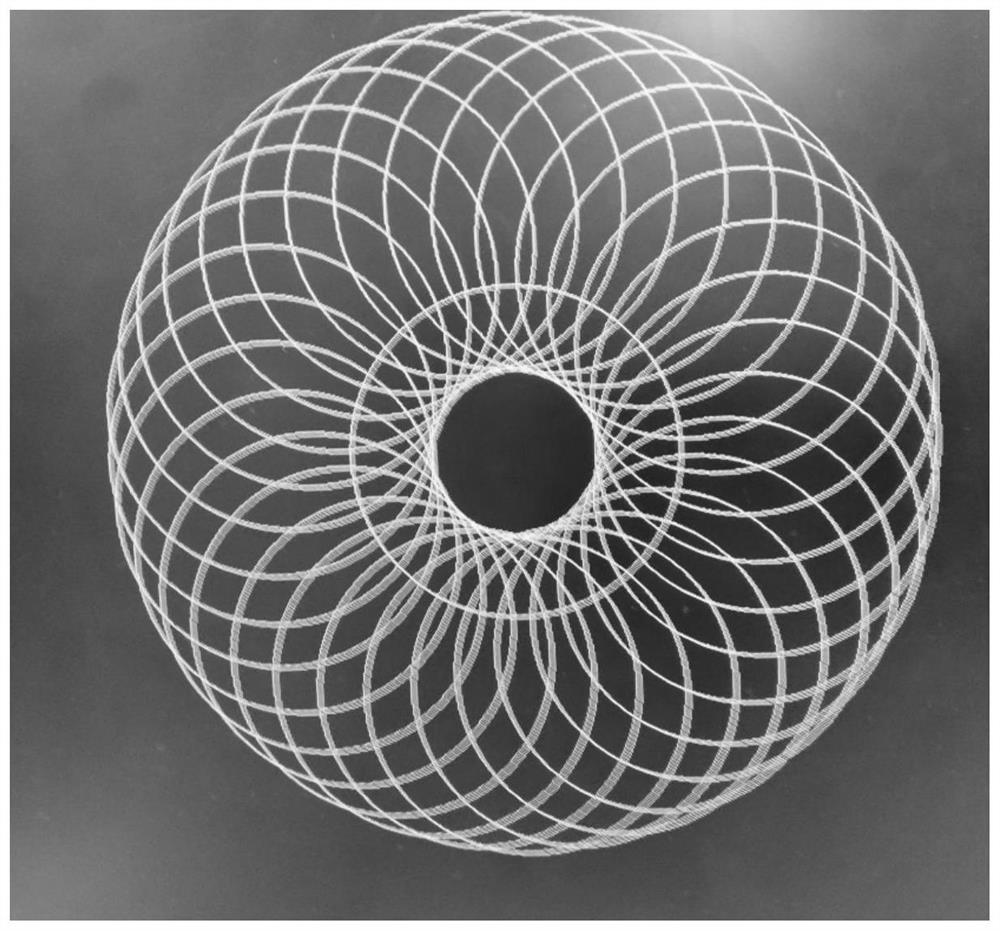

[0049] S2. Pre-design the laser reaming data, and form a set of laser drilling data with the same diameter through multiple small holes. The size of Skip Via aperture is divided to determine the number of holes in 30-40 holes, and the laser reaming data is input into the laser drilling machine;

[0050] S3. Set the laser drilling method according to the aperture size, put the substrate after the Comfor mask window is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com