Aerogel material-containing high efficiency liquid composition extinguishing agent and its preparation method and use

An airgel and composition technology, applied in the direction of fire prevention equipment, etc., can solve problems such as secondary fire accidents, suffocation hazards of operators, flying dust, etc., to prevent the spread of flames, prevent the spread of heat, and block heat transfer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

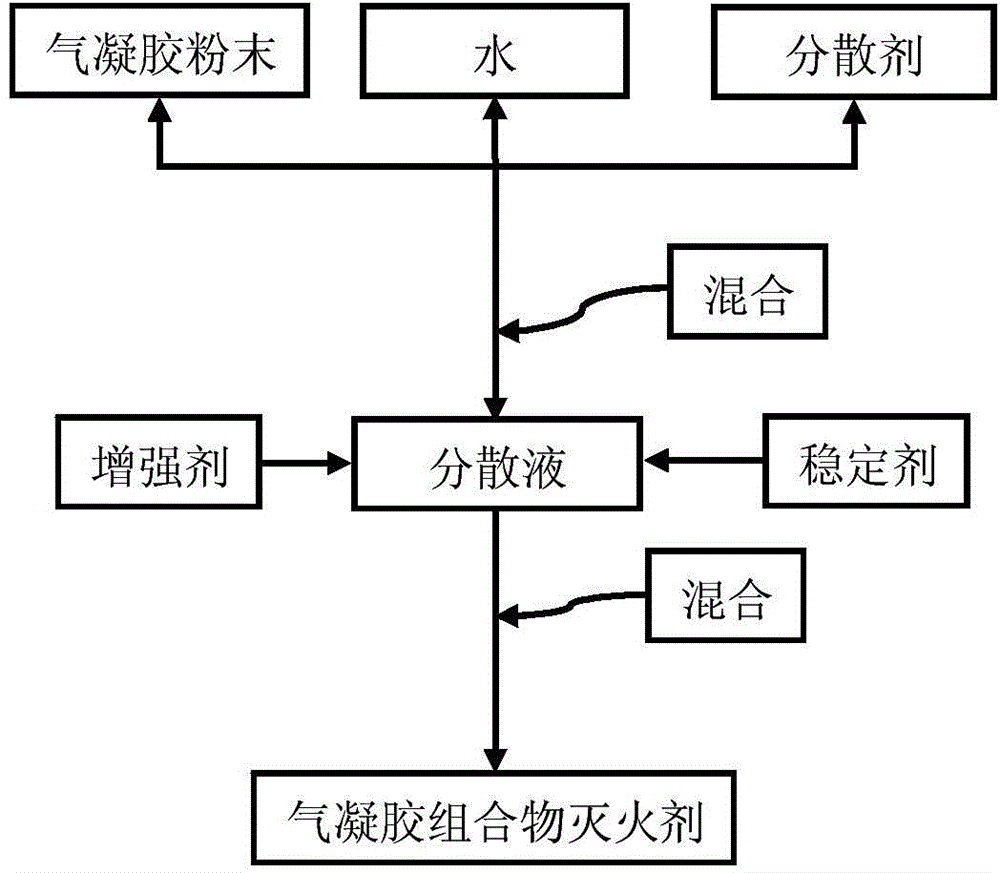

Method used

Image

Examples

Embodiment 1

[0040] Get 100 parts of deionized water by weight, silica airgel powder (density 0.085g / cm 3 , average particle size 50 microns, thermal conductivity 0.025W / mK) 5 parts, sodium dodecyl sulfonate 0.5 parts, use high-speed disperser to disperse, rotating speed 1000rpm, stirring time is 30 minutes to prepare a dispersion liquid. Then add 10 parts of water glass with a modulus of 2.3 and a silica content of 30% and 0.1 part of polyethylene glycol 400 into the prepared dispersion, and stir for 30 minutes with a common mixer at a stirring speed of 100 rpm to prepare an aqueous solution. Extinguishing agent. The prepared water-based fire extinguishing agent is used to extinguish the fire of the wood burned for 5 minutes by air spraying. The fire extinguishing time is 10 seconds. Under the same conditions, other water-based fire extinguishing agents are used to extinguish the fire, and the fire extinguishing time is 30 seconds.

Embodiment 2

[0042] Get 100 parts of deionized water by weight, silica airgel powder (density 0.125g / cm 3 , average particle size 100 microns, thermal conductivity 0.023W / mK) 15 parts, triethanolamine 0.1 part, use high-speed disperser to disperse, rotating speed 2000rpm, stirring time is 30 minutes to prepare a dispersion liquid. Then add 15 parts of silica sol with a silica content of 30% and 0.1 part of dihexyl phthalate to the prepared dispersion, stir for 30 minutes with a common mixer at a stirring speed of 100 rpm, and prepare a water-based fire extinguishing agent . The prepared water-based fire extinguishing agent is used to extinguish the fire of the PP plastic that has been fully burned for 5 minutes by means of air spray. The fire extinguishing time is 15 seconds, and other water-based fire extinguishing agents are used for the same fire, and the fire extinguishing time is 32 seconds.

Embodiment 3

[0044] Get 100 parts of deionized water by weight, silica airgel powder (density 0.105g / cm 3 , particle size 1-50 microns, thermal conductivity 0.023W / mK) 1 part, triethanolamine 0.5 part, use high-speed disperser to disperse, rotating speed 1000rpm, stirring time is 30 minutes to prepare a dispersion liquid. Then add 20 parts of silica sol with a silica content of 30% and 0.1 part of dibutyl phthalate to the prepared dispersion, stir for 35 minutes with a common mixer at a stirring speed of 100 rpm, and prepare a water-based fire extinguishing agent . The prepared water-based fire extinguishing agent is used to extinguish the fire of the PP plastic that has been fully burned for 5 minutes by means of air spray. The fire extinguishing time is 25 seconds, and other water-based fire extinguishing agents are used for the same fire, and the fire extinguishing time is 32 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com