Process for producing pink oyster mushrooms by utilizing fungi residues

A technology of fungus residue and powder leveling, applied in the field of edible fungus cultivation, can solve the problems of high cost of incineration or landfill treatment, many varieties of antibiotic residue, and large quality difference, and achieve good water holding capacity, air permeability, and incidence of pests and diseases Low, good product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

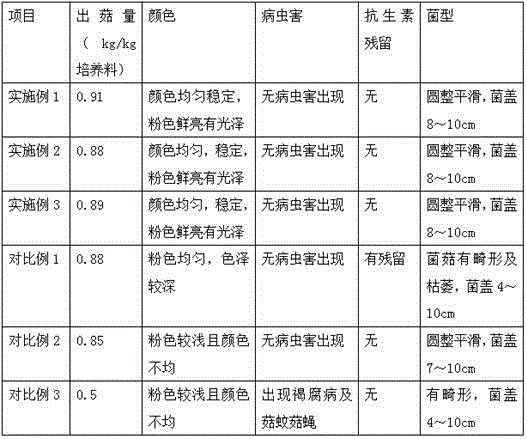

Examples

Embodiment 1

[0023] A kind of technology utilizing bacterium slag to produce powder oyster mushroom, comprises the following steps:

[0024] 1) Take 100 parts by weight of mixed antibiotic residues (β-lactam residues, aminoglycoside residues, tetracycline residues, macrolide residues, quinolone residues), heated to 50- Keep warm at 60°C for 2 hours, lower to room temperature, atomize and spray hydrogen peroxide with a concentration of 95% in the same volume, stir evenly, seal and compact for 1 hour, adjust the water content to 60%, inject ozone and stir for 30 minutes to make ozone and antibiotics The fungus residue is fully mixed, and the ozone concentration is maintained at 1.5g / m3 during the stirring process. After 12 days of ventilated storage, the water content is adjusted to 40%, and proteolytic enzymes (serine protease and aspartic acid protease with a mass ratio of 1:1:1:1) are added. , sulfhydryl protease, metalloprotease mixed), added at a concentration of 1.0g / m3, fermented at 2...

Embodiment 2

[0029] A kind of technology utilizing bacterium slag to produce powder oyster mushroom, comprises the following steps:

[0030] 1) Take 80 parts by weight of antibiotic residues (β-lactam residues, aminoglycoside residues), heat to 50-60°C for 2 hours, cool down to room temperature, and atomize and spray to a concentration of 95% in the same volume. % hydrogen peroxide, stirred evenly, sealed and compacted for 1 hour, adjusted the water content to 60%, injected ozone and stirred for 30 minutes, so that the ozone and antibiotic residues (serine protease, aspartic acid protease, sulfhydryl protease, metalloprotease) fully Mixing, keep the ozone concentration at 1.5g / m3 during the stirring process, adjust the water content to 40% after ventilating for 10 days, add proteolytic enzyme at a concentration of 0.8g / m3, ferment for 7 days at 28-32°C, and heat again to 50- Keep warm at 60°C for 2 hours, sterilize and dry for later use;

[0031] 2) Take 100 parts by weight of straw, 60 p...

Embodiment 3

[0035]A kind of technology utilizing bacterium slag to produce powder oyster mushroom, comprises the following steps:

[0036] 1) Take 120 parts by weight of antibiotic residues (β-lactam residues, macrolide residues, quinolone residues), heat to 50-60°C for 2 hours, cool down to room temperature, atomize and spray The hydrogen peroxide with the concentration of 95% in the same volume is stirred evenly, sealed and compacted and left for 1 hour, and the water content is adjusted to 60%, then injected with ozone and stirred for 30 minutes, so that the ozone and antibiotic residues (serine protease, aspartic acid protease, sulfhydryl group) Protease, metalloprotease) are fully mixed, the ozone concentration is maintained at 1.5g / m3 during the stirring process, after 15 days of ventilated storage, the water content is adjusted to 40%, proteolytic enzymes are added at a concentration of 1.0g / m3, and fermented at 28-32°C for 7 days , heated again to 50-60°C for 2 hours, sterilized a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com