Reaction cavity and semiconductor processing device

A reaction chamber and process chamber technology, which is applied in the manufacture of semiconductor/solid state devices, discharge tubes, electrical components, etc., can solve the problems of inductively coupled plasma ignition difficulty, unfavorable process stability, deterioration of etching uniformity, etc. Achieve the effect of avoiding high ignition voltage damage to the substrate, avoiding high ignition voltage and improving etching uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

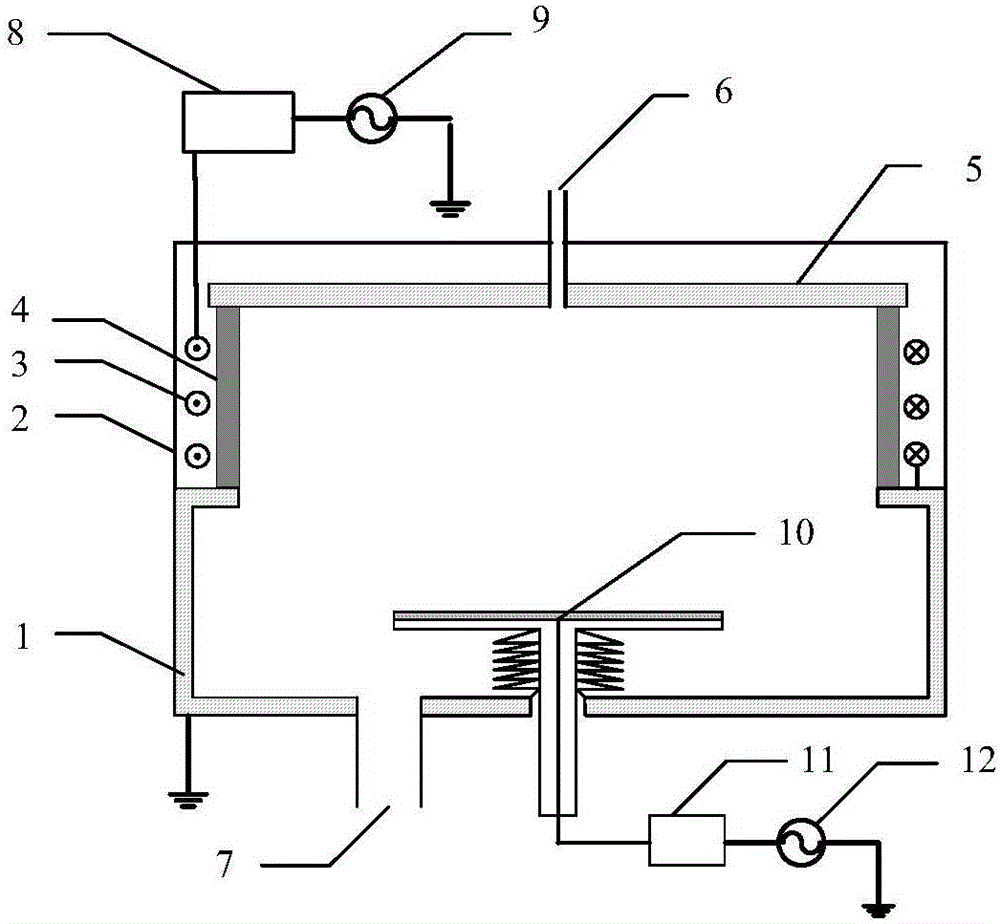

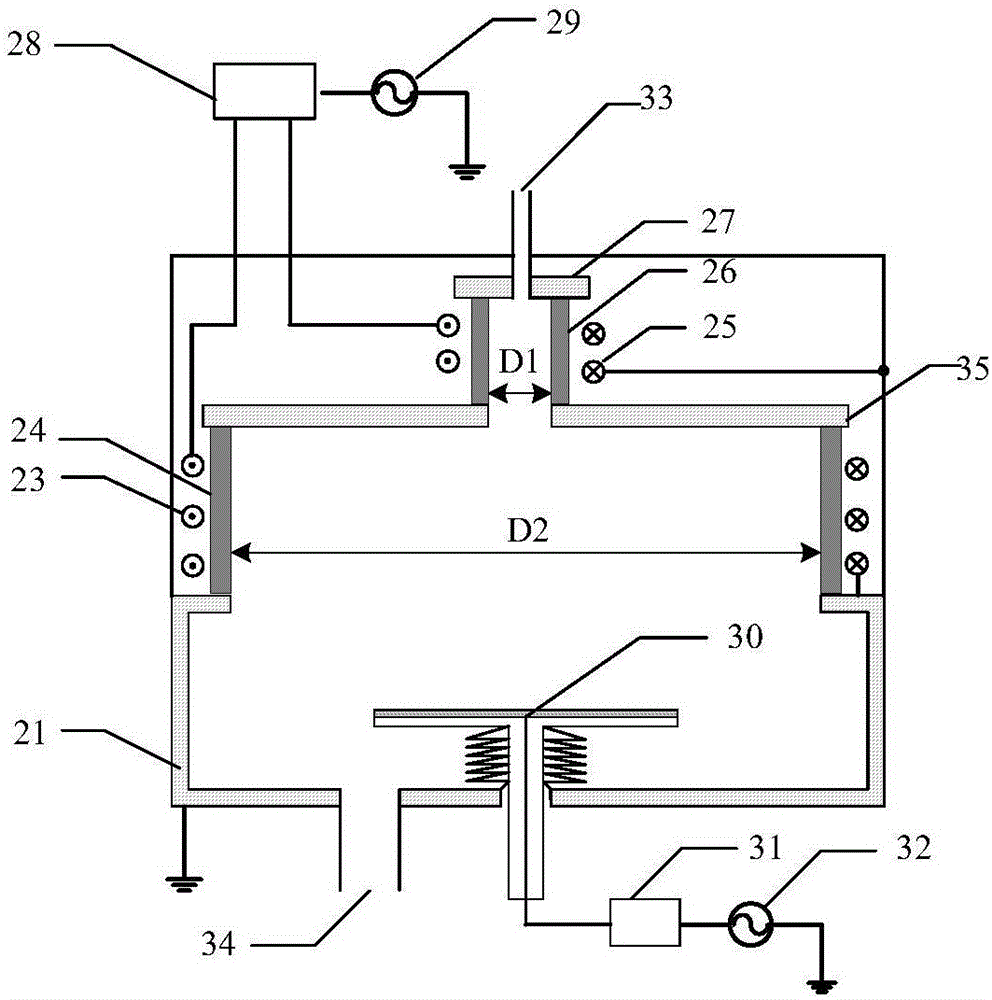

[0024] In order for those skilled in the art to better understand the technical solution of the present invention, the reaction chamber and semiconductor processing equipment provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

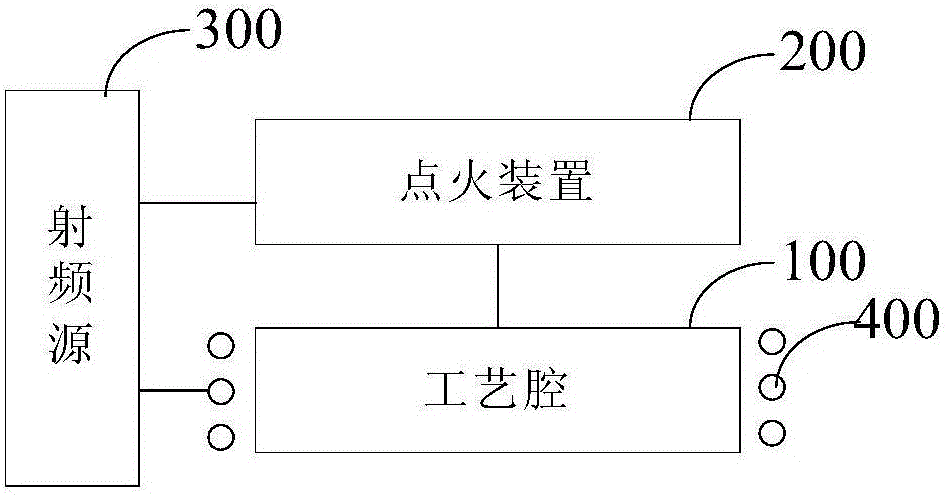

[0025] figure 2 Schematic block diagram of the reaction chamber provided for the present invention. see figure 2 , the reaction chamber includes a process chamber 100 for generating plasma, an ignition device 200 and a radio frequency source 300, wherein a first radio frequency coil 400 is arranged around the process chamber 100 . The ignition device 200 is disposed on the top of the process chamber 100 for igniting the plasma located in the part of the ignition device 200 . The radio frequency source 300 is used to respectively provide radio frequency energy to the first radio frequency coil 400 and the ignition device, and by distributing and adjusting the radio frequency energy obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com