Mould-proof wallpaper loaded with medicine-loading chitosan and preparing method of mould-proof wallpaper

A technology of chitosan and chitosan microspheres, applied in special paper, paper, papermaking and other directions, can solve the problem of poor anti-mildew effect, etc., and achieve the effects of high retention rate, good performance and high drug loading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

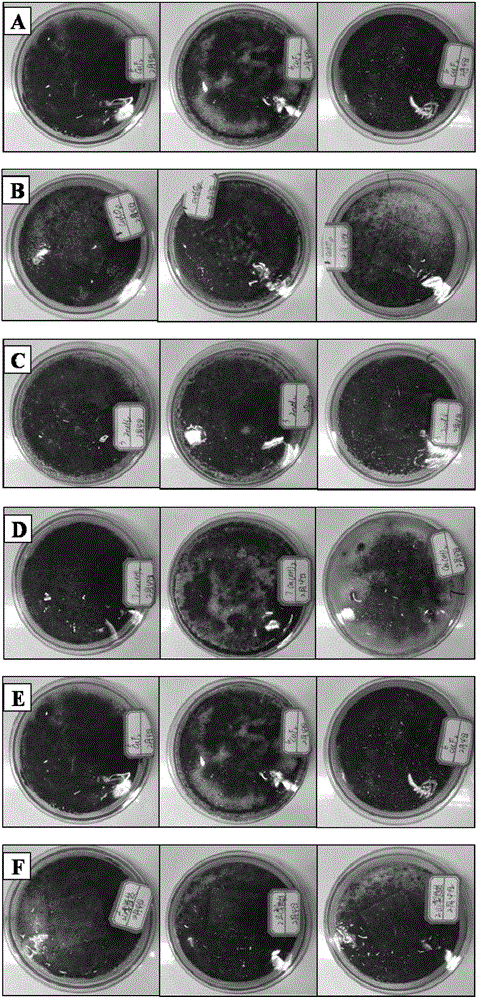

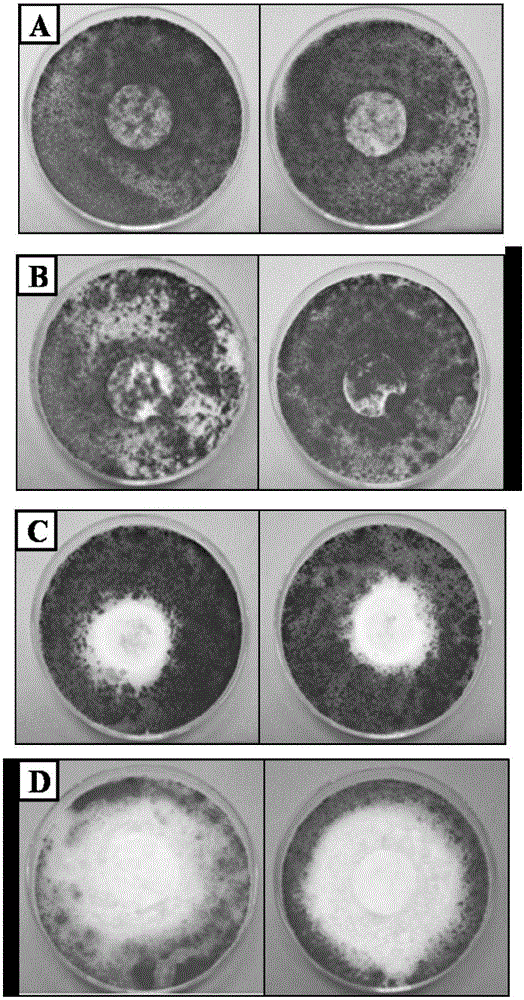

Image

Examples

preparation example Construction

[0037] The invention provides a kind of preparation method of drug-loaded chitosan, and described preparation method comprises the following steps:

[0038] Configure the aqueous solution of sodium tripolyphosphate with a concentration of 2-3g / L as the cross-linking agent, and configure the aqueous solution of anti-mold and antibacterial agent with a concentration of 0.5-3g / L;

[0039] Add chitosan in 0.5-2% glacial acetic acid solution, fully dissolve, and adjust the pH value of the solution to 2-4, and prepare a chitosan / glacial acetic acid mixed solution with a chitosan concentration of 4-16g / L as Carrier;

[0040] Mix the aqueous solution of the antimold and antibacterial agent with the crosslinking agent at a volume ratio of 1 to 2:1 to obtain a mixed solution of the antimold and antibacterial agent, then slowly drop the mixed solution of the antimold and antibacterial agent into the chitosan / glacial acetic acid solution, Stir at room temperature for 2~4h, until the mixe...

Embodiment 1

[0054] 1, prepare drug-loaded chitosan earlier, it comprises the following steps:

[0055] The configuration concentration is 2g / L sodium tripolyphosphate aqueous solution as the crosslinking agent, and the configuration concentration is 3g / L anti-mold and antibacterial agent aqueous solution; the anti-mold and anti-bacterial agent in the anti-mold and anti-bacterial agent aqueous solution is sodium fluoride.

[0056] Chitosan was added in 0.5% glacial acetic acid solution, fully dissolved, and the pH value of the solution was adjusted to 2, and the chitosan / glacial acetic acid mixed solution with a chitosan concentration of 6 g / L was configured as a carrier;

[0057] Mix the antifungal and antibacterial agent aqueous solution with the crosslinking agent at a volume ratio of 1:1 to obtain the antifungal and antibacterial agent mixed solution, then slowly drop the antifungal and antibacterial agent mixed solution into the chitosan / glacial acetic acid solution, at room temperatur...

Embodiment 2

[0063] 1, prepare drug-loaded chitosan earlier, it comprises the following steps:

[0064] The configuration concentration is 2g / L sodium tripolyphosphate aqueous solution as the crosslinking agent, and the configuration concentration is 3g / L anti-mold and anti-bacterial agent aqueous solution, the anti-mold and anti-bacterial agent in the anti-mold and anti-bacterial agent aqueous solution is copper fluoride.

[0065] Chitosan was added in 0.5% glacial acetic acid solution, fully dissolved, and the pH value of the solution was adjusted to 2, and the chitosan / glacial acetic acid mixed solution with a chitosan concentration of 6 g / L was configured as a carrier;

[0066] Mix the antifungal and antibacterial agent aqueous solution with the crosslinking agent at a volume ratio of 1:1 to obtain the antifungal and antibacterial agent mixed solution, then slowly drop the antifungal and antibacterial agent mixed solution into the chitosan / glacial acetic acid solution, at room temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com