Method for recovering valuable metals from complex high-arsenic-and-copper smelting flue dust

A valuable metal, copper smelting technology, applied in the field of metallurgy, to achieve the effect of good utilization and reasonable technical arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

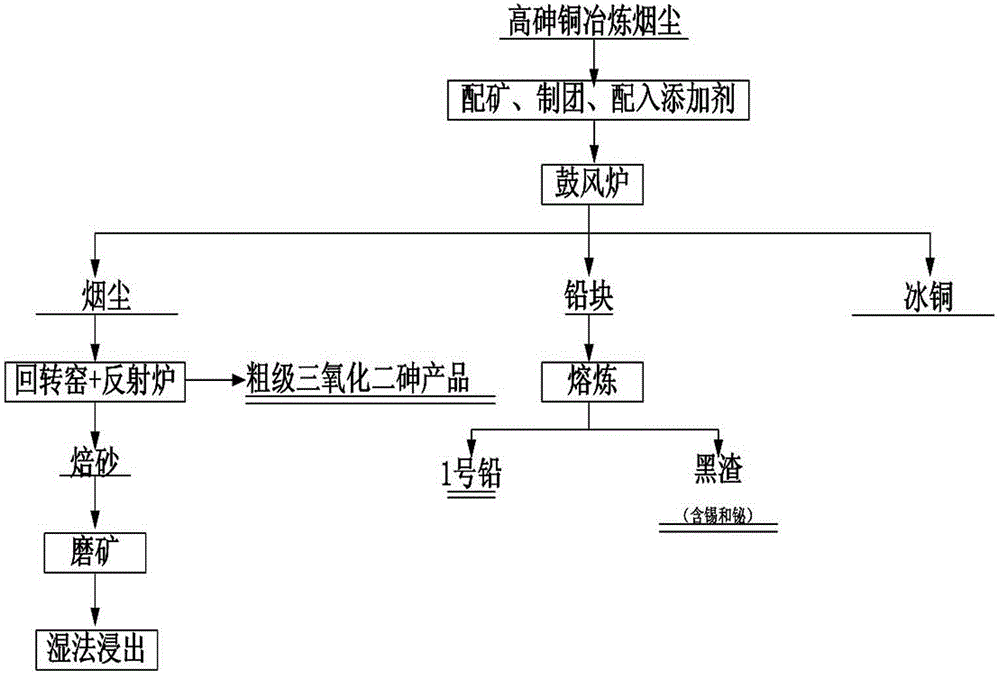

Method used

Image

Examples

Embodiment 1

[0015] Example 1: 1.2 tons of high-arsenic copper smelting dust (containing: 14.62% arsenic, 17.6% lead, 3.62% bismuth, 3.18% copper, 1450g / t indium, 4.27% tin) was put into a blast furnace for reduction smelting, and the smelting temperature was 1100~1300℃, the reaction time is 8 hours, the obtained soot contains 3280g / t indium and 38% arsenic; the obtained metal lead contains 89% lead, 2.1% tin, and 2.8% bismuth; the slag contains 3.68% copper.

[0016] The dust obtained is dearsenized by rotary kiln and reverberatory furnace. The temperature of rotary kiln is 800-900°C, the temperature of reverberatory furnace is 800-900°C, the purity of arsenic trioxide is 93.87%, and the arsenic content in the final calcined sand is 0.95%, the indium content is 4800g / t, the calcine is leached with 180g / L sulfuric acid, and replaced with zinc powder to obtain sponge indium.

[0017] The metal lead obtained is made of a smelting pot, the temperature for removing impurities from the metal le...

Embodiment 2

[0019] Example 2: Put 1.2 tons of high-arsenic copper smelting dust (containing: 17.45% arsenic, 14.6% lead, 4.12% bismuth, 3.52% copper, 1150g / t indium, 3.45% tin) into the blast furnace for reduction smelting, and the smelting temperature is 1150℃, the reaction time is 8 hours, the obtained smoke contains 3200g / t indium and 37% arsenic; the obtained metal lead contains 93% lead, 2.9% tin, and 2.6% bismuth; the slag contains 3.5% copper.

[0020] The obtained soot is dearsenized by rotary kiln and reverberatory furnace. The temperature of rotary kiln and reverberatory furnace is 800-900°C. The purity of arsenic trioxide is 93.76%. The arsenic content in the final calcined sand is 1.2%, the indium content is 4821g / t, the calcine is leached with 180g / L sulfuric acid, and replaced with zinc powder to obtain sponge indium.

[0021] The metal lead obtained is made of a smelting pot, the temperature for removing impurities from the metal lead is 800-1000° C., and the addition amoun...

Embodiment 3

[0023] Example 3: Example 1: Put 1.2 tons of high-arsenic copper smelting dust (containing: 19.63% arsenic, 18.82% lead, 4.82% bismuth, 3.93% copper, 1450g / t indium, 5.77% tin) into the blast furnace for reduction smelting , the smelting temperature is 1300°C, and the reaction time is 8 hours. The obtained smoke contains 3023g / t indium and 36% arsenic; the obtained metal lead contains 87.2% lead, 2.3% tin, and 2.5% bismuth; the slag contains 3.21% copper .

[0024] The obtained soot is dearsenized by rotary kiln and reverberatory furnace. The temperature of rotary kiln is 800-900°C, the temperature of reverberatory furnace is 800-900°C, the purity of arsenic trioxide is 93.57%, and the arsenic content in the final calcined sand is 1.5%, the indium content is 4802g / t, the calcine is leached with 180g / L sulfuric acid, and replaced with zinc powder to obtain sponge indium.

[0025] The metal lead obtained is made of a smelting pot, the temperature for removing impurities from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com