Use of ethanol plant by-products for yeast propagation

A by-product, ethanol technology, applied in the direction of fermentation, biofuel, etc., to achieve good utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

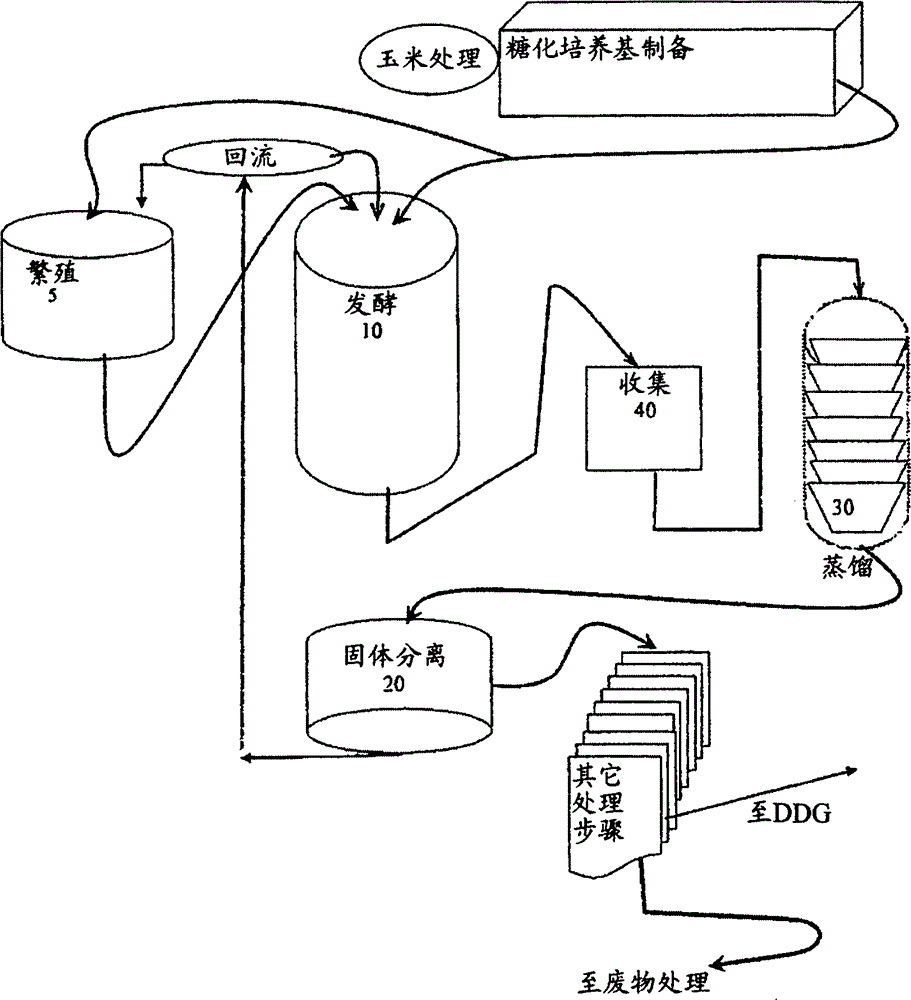

Method used

Image

Examples

Embodiment 1

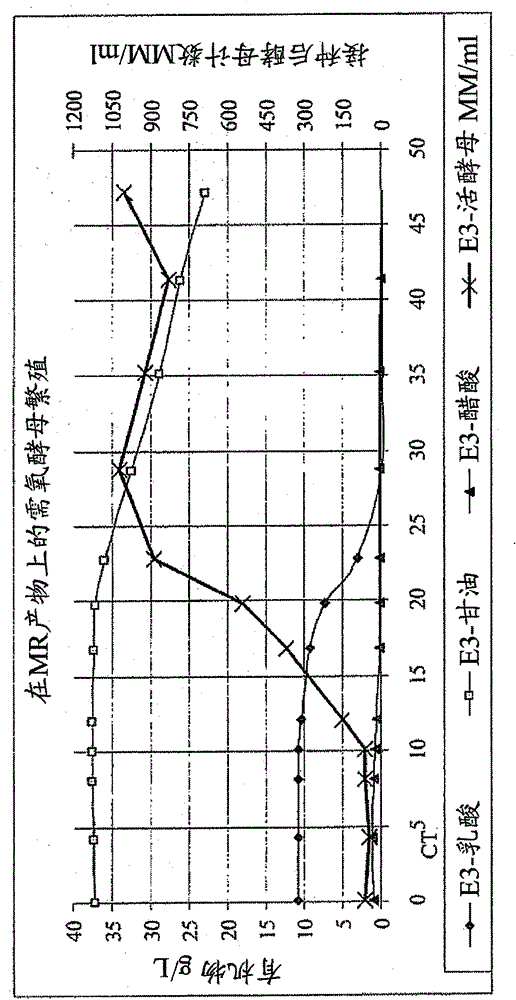

[0050] Example 1 reports batch fermentor cultivation of Saccharomyces cerevisiae utilizing organic acids and glycerol obtained as by-products of evaporation from reflux from a dry mill ethanol production facility. Batch yeast propagation was performed in two 3.5L fermentors. Concentrate OAG to between 5 and 10 times the original OAG concentration.

[0051] The pH of the culture was adjusted to 4.4 using sodium hydroxide. Nitrogen was also added to the mixture as an ammonium salt until the nitrogen concentration (as ammonia) was 2.5 g / L. The inoculation ratio was 1% v / v.

[0052] The results are shown in Figure 4 middle. Organic acids are preferred metabolites of yeast. The preference for glycerol is secondary. Organic acid depletion is indicated by a significant increase in dissolved oxygen concentration, which is not shown in the figure.

[0053] Cultures reach approximately 9 x 10 in 24 hours 8 cells / ml and a carbon source of 15-17 g / L was used during this time. La...

Embodiment 2

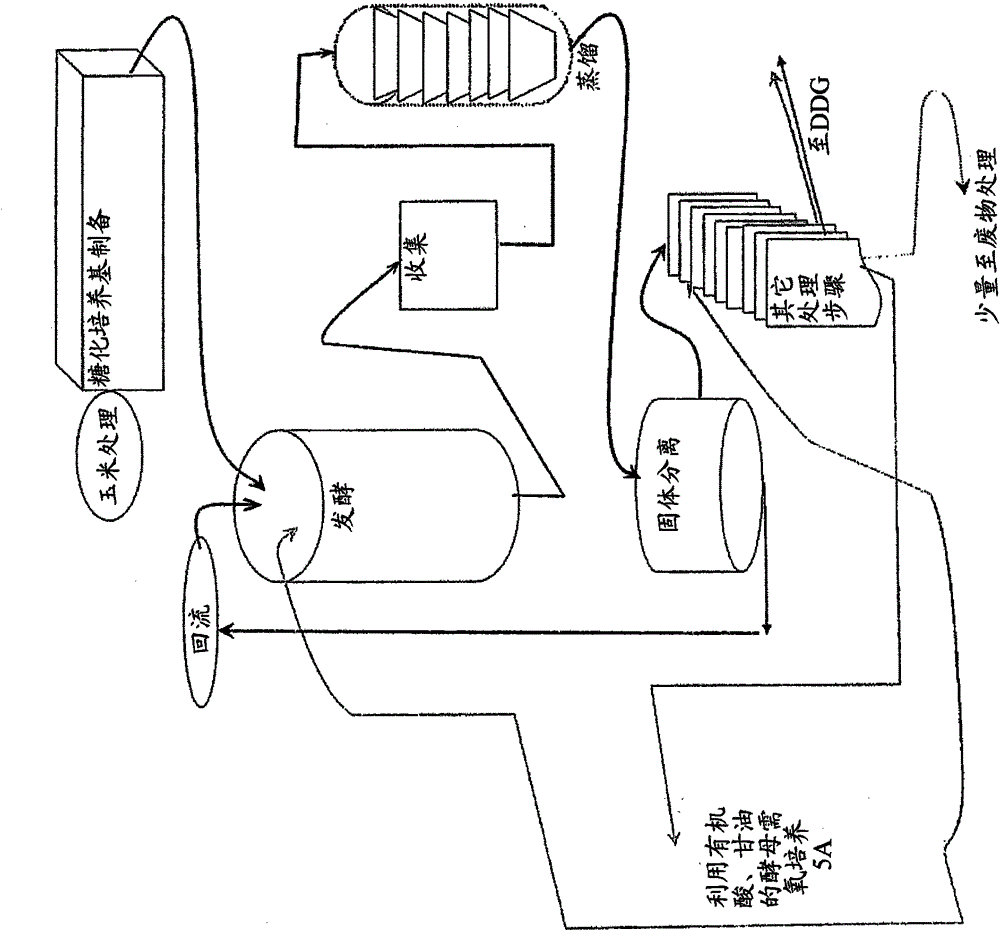

[0055] Example 2 reports the cultivation of Saccharomyces cerevisiae utilizing organic acids and glycerol obtained as by-products of evaporation from reflux from a dry mill ethanol production facility. Fermentation was initially carried out as a batch process, and then when more than 5 x 10 was considered sufficient 8 The yeast mass was then moved to a continuous fermenter.

[0056] After being moved to continuous fermentation mode, the fermentation quickly reached steady state conditions with a retention time of 5 to 6 hours. like Figure 5 As shown, the culture density, as expressed by optical density (OD at 660 nm) or by viable yeast cell counts, remained stable over the duration of the continuous feed / drop phase, which was maintained for 90 hours. About 16 fermentor volumes were produced during this period. The average yeast concentration during the continuous phase was 1.2 x 10 9 cells / ml.

[0057] Image 6 The consistency of the fermentation described in this examp...

Embodiment 3

[0059] Example 3 shows yeast culture utilizing organic acids according to another embodiment of the present invention. The conditions were the same as in Example 2, but the organic acid was not concentrated. The results of this example are shown in Figure 7 . Cultivation was limited by low substrate concentration, as indicated by low optical density and yeast concentration when compared to the results of Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com