One-step vulcanizing assembling mold for large-tilt-angle flange conveying belt and application method thereof

A technology of vulcanization combination and conveyor belt, which can be used in applications, belts, household appliances, etc., can solve the problems of polluting the environment and wasting labor, and achieve the effect of saving social resources, saving production time, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings, but the scope of protection of the present invention is not limited thereto, and any person familiar with the art will not obtain transformation through creative work within the technical scope disclosed in the present invention. , should be covered within the protection scope of the present invention.

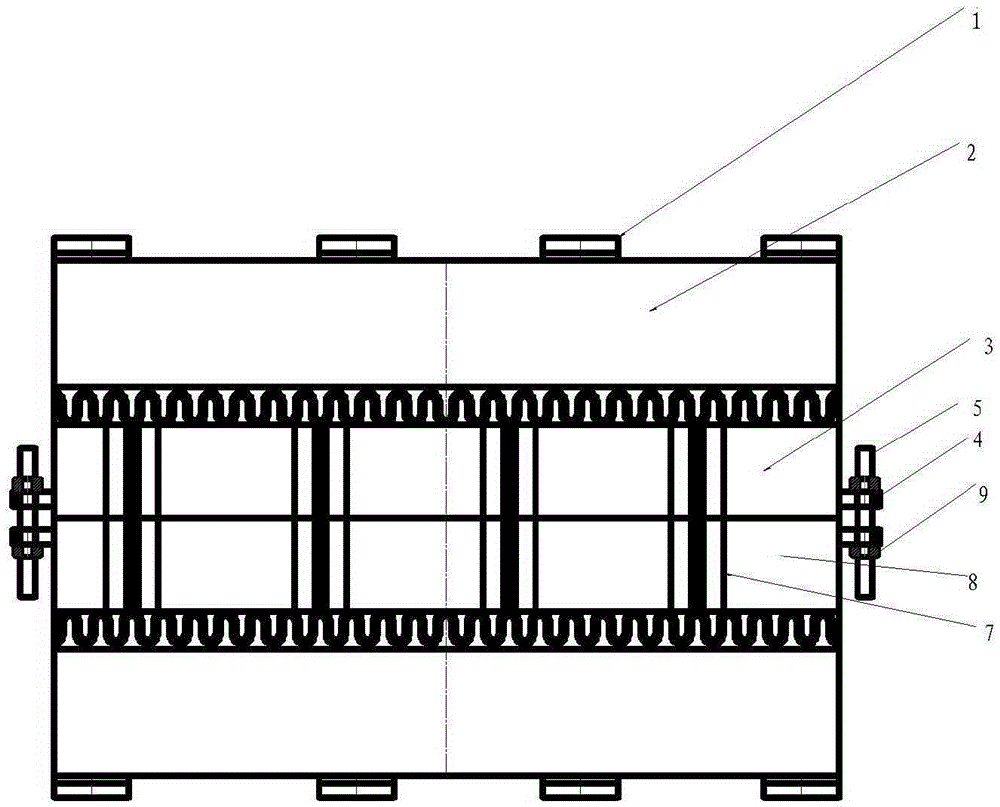

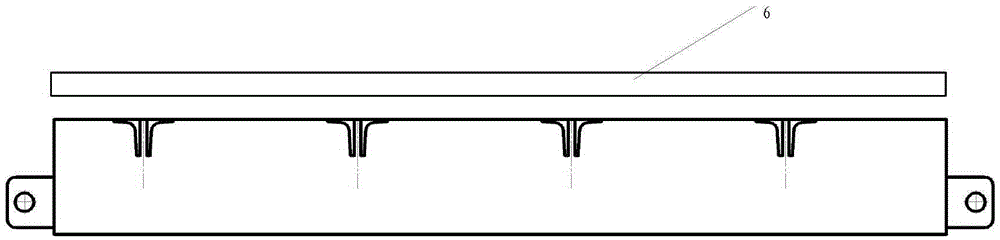

[0026] A one-time vulcanization combination mold for a large-inclination sidewall conveyor belt, including a skirt mold set and a bottom plate 6; the skirt mold set includes an inner module 3 and an outer module 2, and the cavity of the inner module 3 and the outer module 2 cooperate to form waves Shape; the bottom surface of the inner module 3 is also provided with a groove 7 .

[0027] The inner module 3 and the inner module one 8 are placed back to back, and the bolts 5 pass through the bolt holes 4 on one side of the inner module 3 to connect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com