Method for reducing DHA (docosahexaenoic acid) oil anisidine value

A technology for anisidine value and oil, which is applied in the field of biochemistry, can solve problems such as increased risk, toxicity, increased production cost and the like, and achieves the effect of reducing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

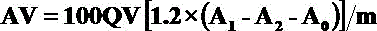

[0026] Embodiment 1: This embodiment illustrates the assay method of anisidine value

[0027] The detection of the anisidine value, according to the detection method of the anisidine value described in the national standard GBT 24304-2009, determines the oil anisidine value, and the specific method is:

[0028] Preparation of anisidine reagent: Take an X ml volumetric flask, directly weigh 0.0025X g p-methoxyaniline into it, dissolve it to the mark with acetic acid, and store it away from light.

[0029] Preparation of the test solution: Weigh an appropriate amount of the prepared fish oil concentrate, accurate to 1mg, put it directly into a 25mL volumetric flask, dissolve it with 5mL-10mL isooctane, and dilute to the mark with the same solvent.

[0030] Determination of unreacted solution: Use a pipette to absorb 5mL of the test solution into a stoppered test tube, add 1mL of glacial acetic acid solution with a pipette, cover the stopper and shake well. Place in a dark place...

Embodiment 2

[0042] Embodiment 2: This embodiment illustrates the method for reducing DHA oil anisidine value

[0043] Fill the reaction vessel with nitrogen protection, take 100g of oil with an AV value of 19.7 and a DHA content of 36.81%, add 5ml (equivalent to 5.0g) of diethyl malonate, mix well, and heat to 35°C.

[0044] Dissolve 3g of sodium hydroxide in 7.5ml of water, add to the above reaction system, and stir for 30min.

[0045] After the reaction was completed, 15ml of saturated NaCl solution was added, stirred for 30min, and the anisidine value of the oil was measured after sampling and centrifugation.

[0046]After the reaction, the anisidine value decreased to 3.4, the fishy smell of the oil disappeared and had a faint ester fragrance, the oil recovery was 83.2g, and the DHA content was determined to be 36.17%.

Embodiment 3

[0047] Embodiment 3: This embodiment illustrates the method for reducing DHA oil anisidine value

[0048] Fill the reaction vessel with nitrogen protection, take 100g of DHA oil with an AV value of 19.7, add 2.5ml (equivalent to 2.5g) of diethyl malonate, mix well, and heat to 35°C.

[0049] Dissolve 1.5g of sodium hydroxide in 5ml of water, add to the above reaction system, and stir for 30min.

[0050] After the reaction was completed, 15ml of saturated NaCl solution was added, stirred for 30min, and the anisidine value of the oil was measured after sampling and centrifugation.

[0051] After the reaction, the anisidine value decreased to 9.7, the fishy smell of the oil disappeared and had a faint ester fragrance, and 94.1 g of the oil was recovered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com