Method for reducing anisidine value of high-content fish oil

A technology with high anisidine value and high content, which is applied in the production of fat oil/fat, refining fat oil/fat, and producing fat, etc. It can solve the problems of high energy consumption, short storage period, cumbersome process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

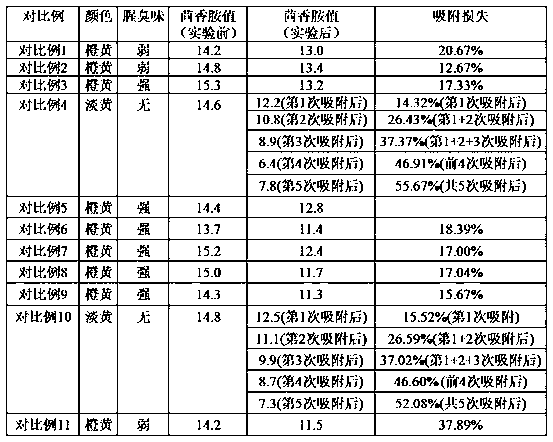

Examples

Embodiment 1

[0085] Under nitrogen protection, take 3.00kg of fish oil with an AV value of 14.7 and a total content of EPA and DHA of 60%, add 15g of attapulgite, mix well, heat to 85°C, absorb for 20min, filter out the adsorbent, and obtain 2.52kg of fish oil .

[0086] Pour the fish oil after adsorption treatment into the feed liquid tank of the wiped-film molecular still (XT-200 type), carry out molecular distillation at 105°C and 10Pa, the feeding rate is 3±0.5kg / h, and the scraping film rate is 110r / min , to obtain 2.01 kg of concentrate.

[0087] Within 24 hours after the molecular distillation was completed, under the protection of nitrogen, 300g of activated clay and 102g of activated carbon were added to the above concentrate, mixed evenly, heated to 85°C, adsorbed for 10min, and filtered off the adsorbent to obtain 1.57kg of the product.

Embodiment 2

[0089] Under the protection of nitrogen, take 3.00kg of fish oil with an AV value of 14.8 and a total content of EPA and DHA of 84%, add 300g of diatomaceous earth and 300g of activated carbon, mix well, heat to 60°C, absorb for 15min, and filter out the adsorbent to obtain Fish oil 1.82kg.

[0090] Pour the fish oil after adsorption treatment into the feed liquid tank of the wiped film molecular still (XT-200 type), carry out molecular distillation at 85°C and 7Pa, the feed rate is 3±0.5kg / h, and the film scraping rate is 130r / min , to obtain 1.54kg of concentrate.

[0091] Within 24 hours after molecular distillation was completed, under the protection of nitrogen, 7.7g of activated alumina was added to the above concentrate, mixed evenly, heated to 50°C, adsorbed for 30min, and filtered off the adsorbent to obtain 1.48kg of the product.

Embodiment 3

[0093] Under nitrogen protection, take 3.00kg of fish oil with an AV value of 13.4 and a total content of EPA and DHA of 72%, add 450g of silica gel, mix well, absorb at 5°C for 20min, and filter out the adsorbent to obtain 2.12kg of fish oil.

[0094] Pour the fish oil after adsorption treatment into the feed liquid tank of the wiped film molecular still (XT-200 type), carry out molecular distillation at 60°C and 8Pa, the feed rate is 3±0.5kg / h, and the film scraping rate is 120r / min , to obtain 1.78kg of concentrate.

[0095] Within 24 hours after molecular distillation was completed, under the protection of nitrogen, 53.4 g of bentonite was added to the above concentrate, mixed evenly, adsorbed at 5°C for 25 min, and the adsorbent was filtered off to obtain 1.69 kg of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com