Thermoset high-flame-retardant lusterless ink used for PET substrate

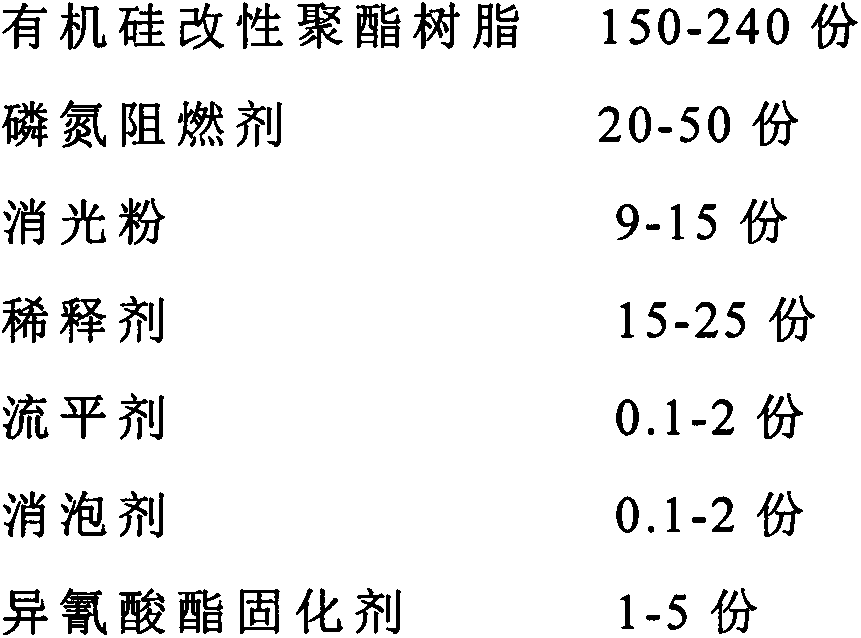

A matte ink, thermosetting technology, applied in the field of ink, can solve the problems of PET materials that cannot be used on a large scale, product performance degradation, damage to coating adhesion, etc., and achieve the effects of improving interface effects, less environmental pollution, and improving flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Mix 36g FR-TM-B flame retardant (Nantong New Jersey New Material Company), 100g of organosilicon modified polyester resin ES-008 and 80g of organosilicon modified polyester resin ES-0109P (Wuxi Huizhi Technology Co., Ltd. ), 12g matting powder OK-500 (Degussa) and 15g methyl ethyl ketone, 1500rpm high-speed dispersion for 30 minutes; 306 (German BYK Chemical Co., Ltd.), 800rpm low-speed dispersion for 10 minutes to obtain the main agent; add 2.5g HDI hardener TIN-22 (Deqian) and 5g methyl ethyl ketone to the main agent, stir evenly to obtain a transparent fluid, which is PET-based Materials with thermosetting high flame retardant matte ink.

Embodiment 2

[0042] Mix 30g FR-TM-B, 90g silicone modified polyester resin ES-008 and 70g silicone modified polyester resin ES-0109P, 10g matting powder Tosoh E-1011 and 18g butanone, 1500rpm high-speed dispersion 30 minutes; then add 0.6g leveling agent BYK-O54, 0.4g defoamer BYK-306, disperse at 800rpm for 10 minutes at low speed to obtain the main agent; add 3g HDI hardener TIN-22, 2g butanone into the main agent, stir Obtain transparent fluid uniformly, which is a thermosetting high flame retardant matte ink for PET substrates.

Embodiment 3

[0044] Mix 22g flame retardant FR-TM-B, 70g silicone modified polyester resin ES-008 and 100g silicone modified polyester resin ES-0109P, 11g matting powder Tosoh E-1011 and 10g butanone, 1500rpm high-speed dispersion for 30 minutes; then add 0.3g leveling agent BYK-O54, 0.5g defoamer BYK-306, 800rpm low-speed dispersion for 10 minutes to obtain the main agent; 2.9g HDI hardener Deqian TIN-22, 10g methyl ethyl ketone Add it to the main ingredient, stir it evenly to get a transparent fluid, which is a thermosetting high flame retardant matte ink for PET substrates.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com