Copolymers of intrinsic microporosity, and preparation method and application thereof

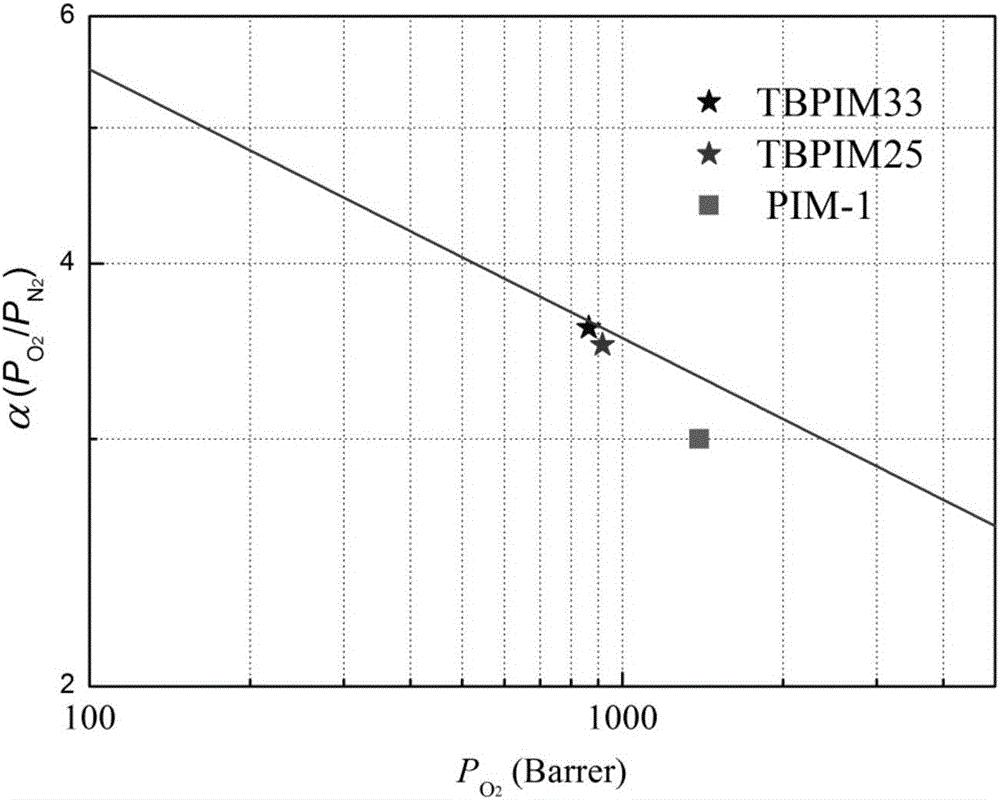

A copolymer and microporous technology, used in separation methods, chemical instruments and methods, methane capture, etc., can solve the problems of high gas permeability and low selectivity, and achieve good repeatability and high gas permeability. , the effect of excellent gas separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The synthesis of embodiment 1TBPIM100

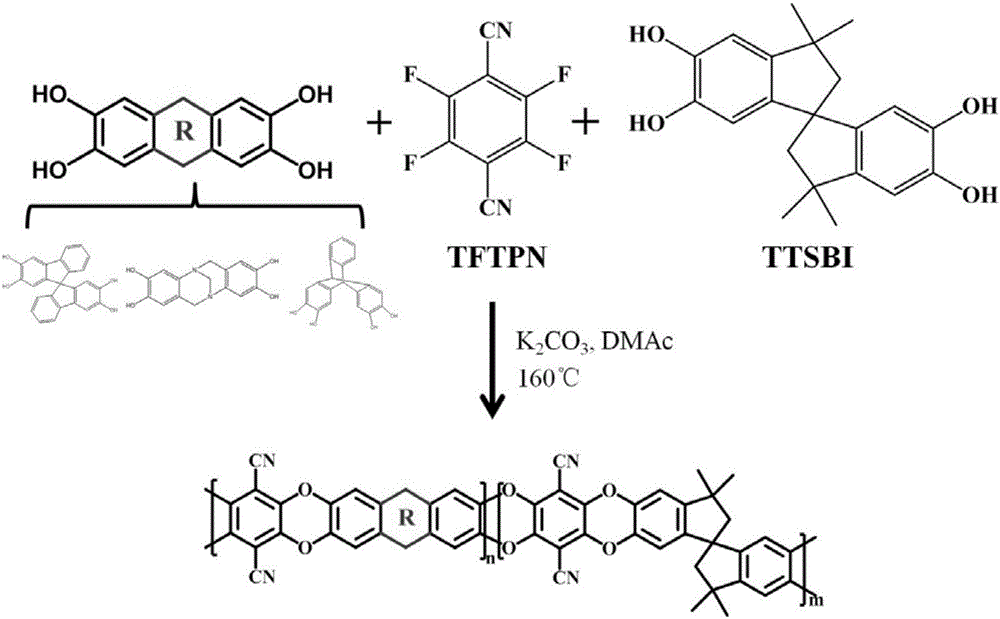

[0067] Add 3.001g of tetrafluoroterephthalonitrile to the reactor equipped with a water separator, and 4.290g of 15mmol 2,3,8,9-tetraphenol hydroxyl-6H,12H-5,11-methylenediphenyl And[b,f][1,5]diazapine, 6.21g anhydrous K 2 CO 3 and 30ml N,N-dimethylacetamide, stir well. Under nitrogen, the reaction device was transferred to an oil bath at 155° C., stirred mechanically, and the reaction was continued for 30 minutes. After the reaction system was cooled, the reaction product was poured into methanol for precipitation. The obtained precipitate was filtered, dissolved in chloroform, and then precipitated into methanol, and repeated three times. Finally, the obtained yellow solid was placed in boiling water, boiled for 5-8 hours, and vacuum-dried at 80° C. for 20 hours to obtain the target product for use. The target product is insoluble in common solvents, specific surface area = 560m 2 / g.

Embodiment 2

[0068] The synthesis of embodiment 2TBPIM60

[0069] Add 3.001g of tetrafluoroterephthalonitrile to the reactor equipped with a water separator, and 2.040g of 5,5',6,6'-tetrahydroxy-3,3',3,3'-tetramethyl Spirobisindene and 2.574 g of 15 mmol 2,3,8,9-tetraphenolic hydroxy-6H,12H-5,11-methylenedibenzo[b,f][1,5]diazocine, 6.21g anhydrous K 2 CO 3 and 30ml N,N-dimethylacetamide, stir well. Under nitrogen, the reaction device was transferred to an oil bath at 155° C., stirred mechanically, and the reaction was continued for 30 minutes. After the reaction system was cooled, the reaction product was poured into 500ml of methanol for precipitation. The obtained precipitate was filtered, dissolved in chloroform, and then precipitated into methanol, and repeated three times. Finally, the obtained fluorescent yellow solid was placed in boiling water, boiled for 5-8 hours, and vacuum-dried at 80° C. for 20 hours to obtain the target product for use. The target product characterizati...

Embodiment 3

[0070] The synthesis of embodiment 3TBPIM40

[0071] Add 3.001g of tetrafluoroterephthalonitrile to the reactor equipped with a water separator, and 3.060g of 5,5',6,6'-tetrahydroxy-3,3',3,3'-tetramethyl Spirobisindene and 1.716 g of 15 mmol 2,3,8,9-tetraphenolhydroxyl-6H,12H-5,11-methylenedibenzo[b,f][1,5]diazalocine, 6.21g anhydrous K 2 CO 3 and 30ml N,N-dimethylacetamide, stir well. Under nitrogen, the reaction device was transferred to an oil bath at 155° C., stirred mechanically, and the reaction was continued for 30 minutes. After the reaction system was cooled, the reaction product was poured into methanol for precipitation. The obtained precipitate was filtered, dissolved in chloroform, and then precipitated into methanol, and repeated three times. Finally, the obtained fluorescent yellow solid was placed in boiling water, boiled for 5-8 hours, and vacuum-dried at 80° C. for 20 hours to obtain the target product for use. The target product characterization data a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com