Method for producing alkoxylate through microchannel reactor

A technology of microchannel reactor and microreactor, which is applied in the field of alkoxylate production, can solve the problems of reducing the mixing effect, sealing carbon black into the product, and long production cycle, so as to improve reaction efficiency and production efficiency, reduce Side reactions occur and the effect of solving heat transfer problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

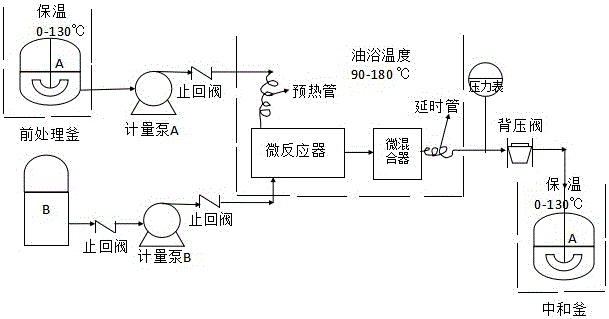

[0069] (1) The device used: a continuous microreactor system, refer to figure 1 The connection of the system device diagram, in which the microchannel reactor adopts the liquid-liquid microreactor (LLMR) of Dalian Weikai Chemical Co., Ltd., and the micromixer adopts the super-focused micromixer (SFIMM-V2-300) of Dalian Weikai Chemical Co., Ltd. . Adjust the length of the delay tube and the material to determine the reaction residence time. The heat exchange medium is high-temperature heat-conducting oil, and the neutralization tank is a 2L conventional alkoxylation small-scale reactor.

[0070] (2) Preparation of Fluid A and Fluid B: Add 150g of active hydrogen-containing compound to the pretreatment tank in advance, add 1‰ catalyst based on the mass percentage of alkoxy compound, and remove the fluid between -0.5MPa±0.5MPa After degassing and degassing, keep warm at 0-130°C as fluid A for standby; ethylene oxide under normal temperature and pressure is used as liquid phase f...

Embodiment 2

[0077] (1) The device used: a continuous microreactor system, refer to figure 1 The connection of the system device diagram, in which the microchannel reactor adopts the MRE microreactor of Guizhou Microchemical Technology Co., Ltd., and the micromixer adopts the internal interdigitated micromixer (HPIMM) of Dalian Weikai Chemical Co., Ltd. Adjust the length of the delay tube and the material to determine the reaction residence time. The heat exchange medium is high-temperature heat-conducting oil, and the neutralization tank is a 2L conventional alkoxylation small-scale reactor.

[0078] (2) Preparation of Fluid A and Fluid B: Add 160g of active hydrogen-containing compound to the pretreatment tank in advance, add 1-9‰ of a catalyst based on the mass percentage of the alkoxy compound, between -0.5MPa±0.5MPa After the degassing is qualified, keep warm at 0-130°C as fluid A for standby; propylene oxide under normal temperature and pressurized conditions is used as liquid phase ...

Embodiment 3

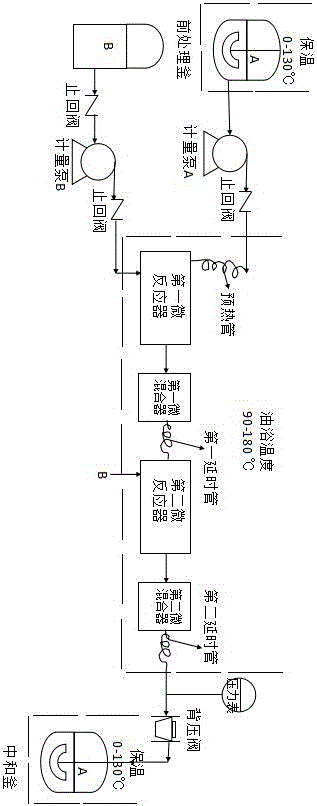

[0085] (1) The device used: a continuous microreactor system, refer to figure 2 The connection of the system device diagram, wherein the microchannel reactor (the first microreactor, the second microreactor) adopts the liquid-liquid phase microreactor (LLMR) of Dalian Weikai Chemical Co., Ltd., and the micromixer (the first micromixer, The second micro-mixer) adopts the micro-mixer of Guizhou Microchemical Technology Co., Ltd. ( MXE ). Adjust the length of the delay tube and the material to determine the reaction residence time. The heat exchange medium is high-temperature heat-conducting oil, and the neutralization tank is a 2L conventional alkoxylation small-scale reactor.

[0086] (2) Preparation of Fluid A and Fluid B: Add 140g of active hydrogen-containing compound to the pretreatment tank in advance, add 1-3‰ catalyst based on the mass percentage of alkoxy compound, between -0.5MPa±0.5MPa After the degassing is qualified, keep warm at 0-130°C as fluid A for standby; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com