Power plant variable-load coal-fired furnace desulfurization wastewater zero discharge system

A technology for desulfurization wastewater and coal-fired boilers, applied in the direction of gaseous effluent wastewater treatment, water aeration, multi-stage water treatment, etc., can solve problems such as increased operating costs, less exhaust gas, increased flue gas humidity, etc., and achieve savings Effects of operating costs, reducing operating costs, and reducing water replenishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

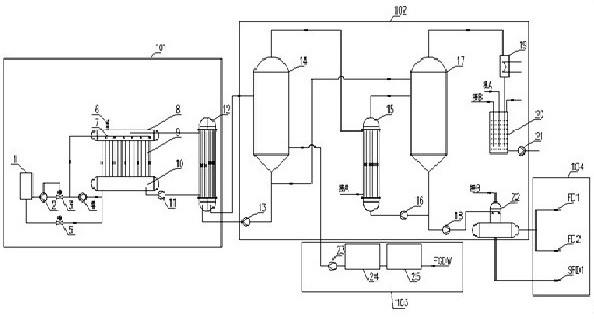

[0046] Such as figure 1 As shown, the zero-discharge system for desulfurization wastewater of coal-fired boilers with variable load in power plants according to the embodiment of the present invention includes an adjustable low-temperature flue gas waste heat recovery and utilization system device 101, a desulfurization wastewater evaporation and concentration system 102 using waste heat as a heat source, and a desulfurization wastewater pretreatment system. The system 103 and the concentrated desulfurization wastewater are finally treated to the zero discharge system 104;

[0047] Among them, the adjustable low-temperature flue gas waste heat recovery and utilization system device 101 is composed of a water tank 1, a cooling and drainage pump 2, a cooling and drainage electric valve 3, an internal circulation water pump 4, a heating and replenishing water valve 5, and an overpressure and non-condensable gas discharge valve 6 , steam collecting tank water distributor 7, steam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com