Aerobic and anaerobic integrated granule sludge reactor and wastewater treatment method thereof

A technology of anaerobic granular sludge and aerobic granular sludge, applied in aerobic and anaerobic process treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of difficult cultivation of aerobic granular sludge , easy disintegration and other problems, to achieve the effect of compact reactor structure, short cultivation time and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

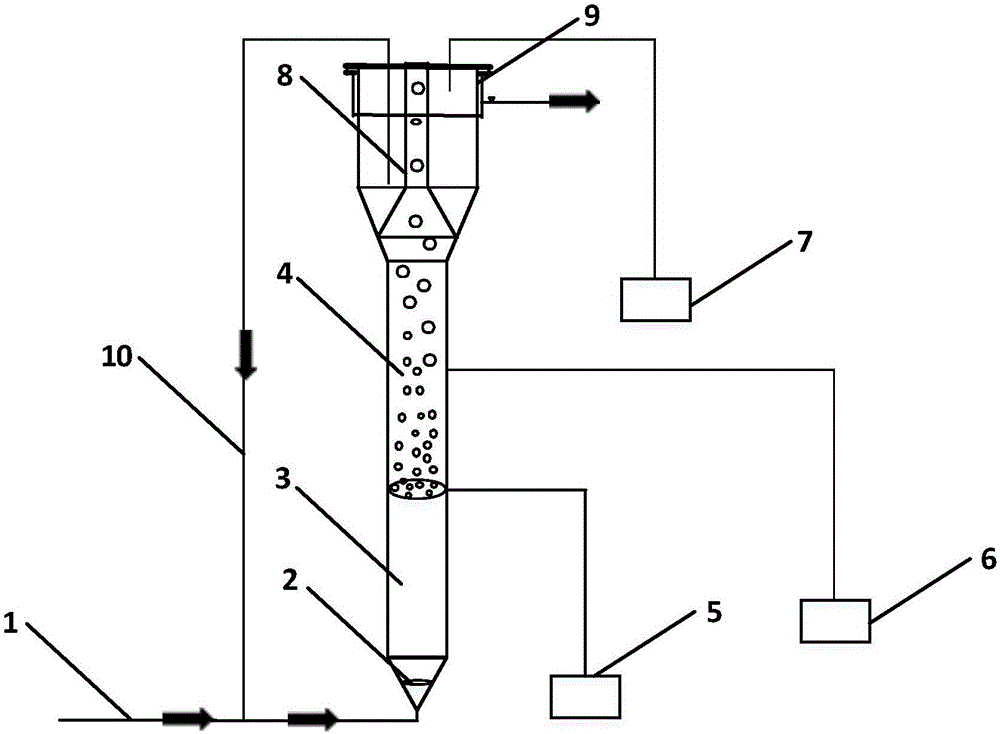

[0030] The reactor adopts a cylindrical structure, the diameter of the reaction zone is 5cm, the height is 50cm, the volume of the reaction zone is 1L, and the diameter of the upper separation zone is 8cm. The reactor is started by inoculating anaerobic granular sludge, and an aeration device is installed on the side of the reactor. The height of the aeration can be adjusted according to the water quality of the effluent; Anaerobic granular sludge will be converted into aerobic granular sludge, and there are both aerobic granular sludge and anaerobic granular sludge in the same reactor; the reactor uses continuous inflow water, and the treatment efficiency is higher than that of traditional sequencing batch. Oxygen particle technology; a three-phase separator is installed on the top, and the three-phase separator realizes the separation of water, gas and mud; the dissolved oxygen automatic feedback device and the pH automatic feedback device are installed in the reactor, and th...

Embodiment 2

[0034] The device and treatment process are as mentioned above, using this device to treat a certain industrial wastewater, the COD of the influent is 290-310mg / L, NH 4 + -N is 95-105mg / L. Influent water enters the anaerobic particle area through the water distribution device at the bottom of the reactor, and most of the organic matter is removed in this area. Sewage flows out of the anaerobic zone into the aerobic granule zone where residual organic matter and nitrogen are removed. The dissolved oxygen automatic feedback control device and pH automatic feedback device installed in the aerobic granular sludge area control the dissolved oxygen and pH to 1.5mg / L and 7.8, respectively. The sewage continues to flow upward, and the three-phase separator at the top of the reactor is used to separate gas, liquid and solid. Part of the effluent is discharged from the reactor through the overflow weir, and the other part is refluxed to the bottom of the reactor through the reflux dev...

Embodiment 3

[0036] The device and treatment process are as mentioned above, the COD of influent nitrogen-containing organic wastewater treated by this device is 500-4000 mg / L, NH 4 + -N is 190~500mg / L, the influent water enters the reactor from the water distribution device at the bottom of the reactor, and then passes through the anaerobic granular sludge area and the aerobic granular sludge area, and the dissolved oxygen installed in the aerobic granular sludge area automatically The feedback control device and pH automatic feedback device control the dissolved oxygen and pH to be between 1-1.5 mg / L and 7.5-7.8 respectively. The sewage continues to flow upwards, and the three-phase separator at the top of the reactor is used to separate gas, liquid and solid. Part of the effluent is discharged from the reactor through the overflow weir, and the other part is refluxed to the bottom of the reactor through the reflux device. The reflux ratio of the effluent is based on The effluent water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com