High-strength and flame-retardant hard polyurethane thermal insulation material for building and preparation method of thermal insulation material

A rigid polyurethane and high-strength technology, which is applied in the field of flame-retardant rigid polyurethane, can solve the problems of affecting the mechanical properties of composite materials, the fire resistance has not been greatly improved, and the industrialization cost is expensive, so as to achieve less addition and high compressive strength and tensile strength, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

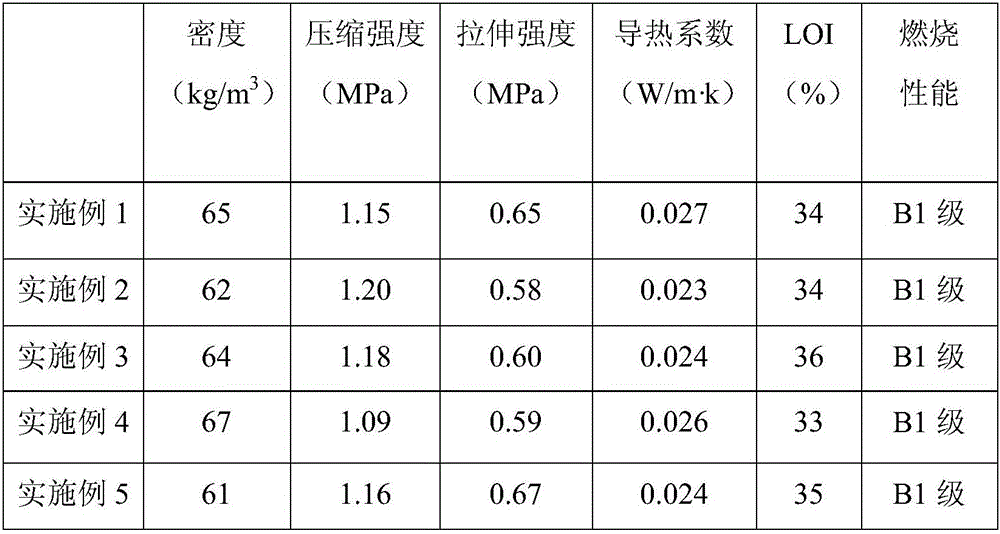

Examples

Embodiment 1

[0028] Modification of asbestos fibers: (1) Cut the asbestos fibers into small sections of 3-10 mm in length, soak them in the configured ammonium chloride aqueous solution with a mass concentration of 5%, stir and disperse them, and keep the temperature at 80°C. Carry out surface etching treatment, take it out after 2 hours of treatment, and dry at 80° C. for 2 hours; (2) configure a silane coupling agent KH540-ethanol mixed solution, wherein the mass fraction of the coupling agent KH540 is 10%, and take the drying method in step (1). The quality of the dried asbestos fiber is 8 times of the coupling dose, soak the dried asbestos fiber in the coupling agent-ethanol solution for 5 hours at room temperature, take it out by ultrasonication, and dry it at 70°C for 4 hours to obtain a new modified asbestos fiber fiber.

[0029] The compound flame retardant is a mixture of inorganic flame retardants and organic phosphate flame retardants in a mass ratio of 1:1.

[0030] The raw ma...

Embodiment 2

[0044] Modification of asbestos fibers: (1) Cut the asbestos fibers into small sections of 3-10mm in length, soak them in the configured ammonium chloride aqueous solution with a mass concentration of 20%, stir and disperse them, and keep the temperature at 100°C. Carry out surface etching treatment, take it out after 4 hours of treatment, and dry at 120°C for 4 hours; (2) Prepare a mixed solution of silane coupling agent KH550-ethanol, wherein the mass fraction of coupling agent KH550 is 15%, and dry it in (1) The final asbestos fiber has a mass 20 times that of the coupling dose. Soak the dried asbestos fiber in (1) in a coupling agent-ethanol solution for 8 hours at room temperature and take it out by ultrasonication, and dry it at 90°C for 6 hours to obtain a new improved Sexual asbestos fibers.

[0045] The compound flame retardant is a mixture of inorganic flame retardants and organic phosphate flame retardants in a mass ratio of 1:1.5.

[0046] The raw material formula...

Embodiment 3

[0062] Modification of asbestos fibers: (1) Cut the asbestos fibers into small sections of 3-10mm in length, soak them in the configured ammonium chloride aqueous solution with a mass concentration of 15%, stir and disperse them, and keep the temperature at 90°C. Carry out surface etching treatment, take it out after 2.5 hours of treatment, and dry at 100°C for 3.5 hours; (2) Prepare a mixed solution of silane coupling agent KH791 / KH901-ethanol, wherein the mass fraction of coupling agent KH550 / KH901 (3:7) 12%, take the asbestos fiber after drying in step (1), its quality is 15 times of the coupling dose, soak the asbestos fiber after drying in the coupling agent-ethanol solution at room temperature and take it out by ultrasonic for 6h, 80 Dry at ℃ for 5.5 hours to obtain new modified asbestos fibers.

[0063] The compound flame retardant is a mixture of inorganic flame retardants and organic phosphate flame retardants in a mass ratio of 1:3.

[0064] The raw material formula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com