Hyper-branched macromolecular flocculation demulsifying agent for treating oil-containing high-salt industrial waste water, and preparation method and use method thereof

A technology of hyperbranched polymer, flocculation demulsifier, applied in chemical instruments and methods, special compound water treatment, water/sludge/sewage treatment, etc. The flocculant has a single function and is difficult to obtain treatment effects, etc., to achieve good demulsification effect, strong flocculation ability, and a large number of effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a preparation method of the above-mentioned hyperbranched polymer flocculation demulsifier for treating oil-containing high-salt industrial wastewater, which is characterized in that it comprises the following steps:

[0034] Add the aqueous solution of the first hyperbranched polyacryloyl ethylenediamine hydrochloride macromonomer dropwise to the mixed aqueous solution formed by the water-soluble monomer and the second hyperbranched polyacryloyl ethylenediamine hydrochloride macromonomer , carry out copolymerization reaction under the existence condition of initiator, obtain hyperbranched macromolecule flocculation demulsifier;

[0035] The preparation method of the first hyperbranched polyacryloyl ethylenediamine hydrochloride macromer or the second hyperbranched polyacryloyl ethylenediamine hydrochloride macromer is:

[0036] In an inert gas environment, acryloylethylenediamine hydrochloride undergoes an addition reaction to obtain...

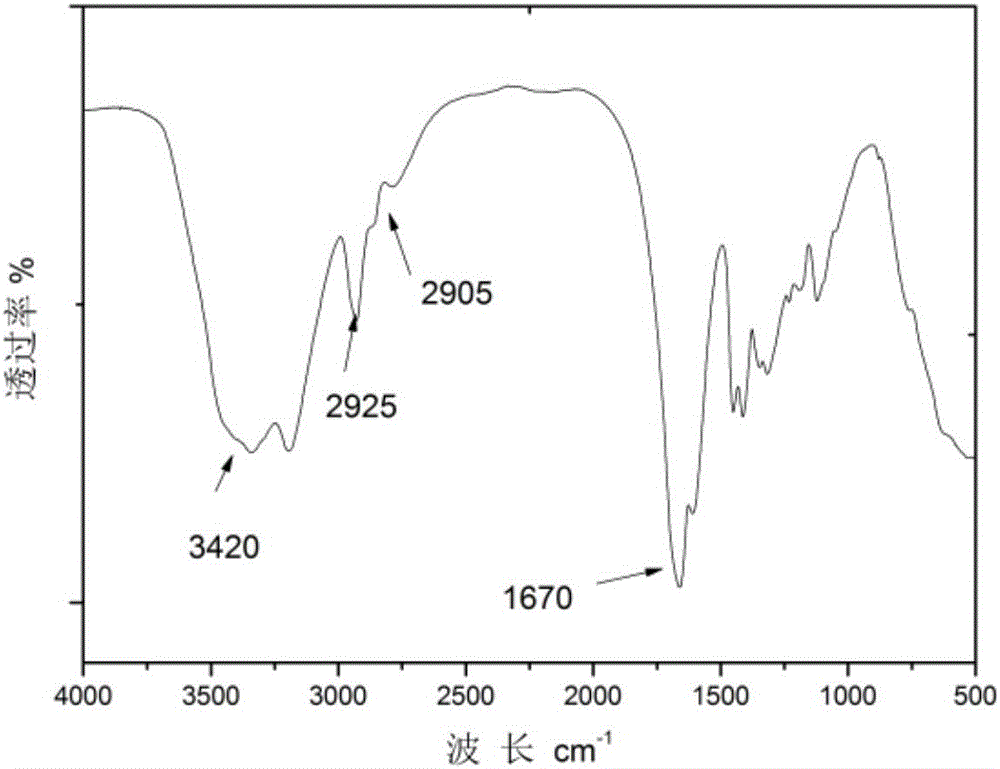

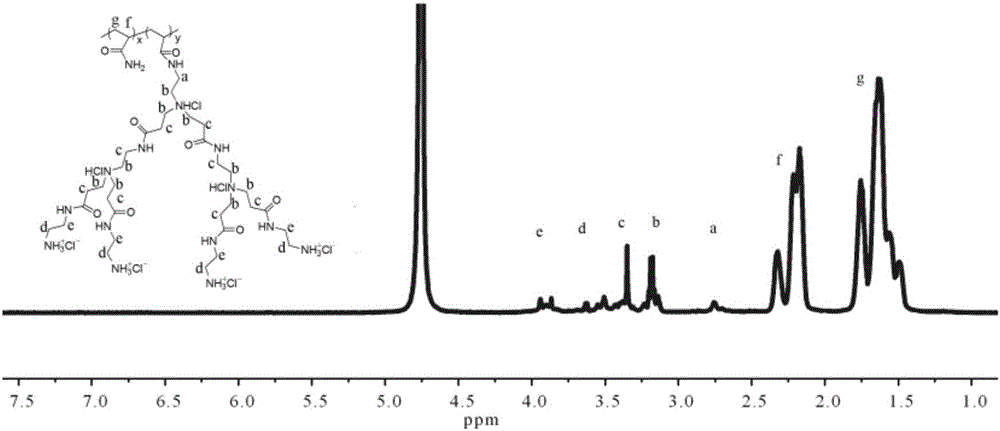

Embodiment 1

[0062] 4g of acryloylethylenediamine hydrochloride was placed in a three-necked flask, and under the protection of nitrogen, the reaction device was placed in high-temperature silicone oil. The temperature was raised to 210° C., the reaction was carried out at this temperature for 4 hours, and then cooled to room temperature. The reaction product was dissolved in 5 ml of deionized water, filtered, and freeze-dried to obtain 3.1 g of polyacryloylethylenediamine hydrochloride as a brown-yellow solid.

[0063] Dissolve 0.1mol methacrylamide and 0.002mol polyacryloylethylenediamine hydrochloride in deionized water, and 0.008mol polyacryloylethylenediamine hydrochloride into a four-necked reaction flask equipped with a condenser, mechanical stirrer, and nitrogen gas inlet. The amine hydrochloride was dissolved in deionized water, and added dropwise into the reaction flask through a constant pressure titration funnel to obtain a mixed solution. Nitrogen gas was passed into the mixe...

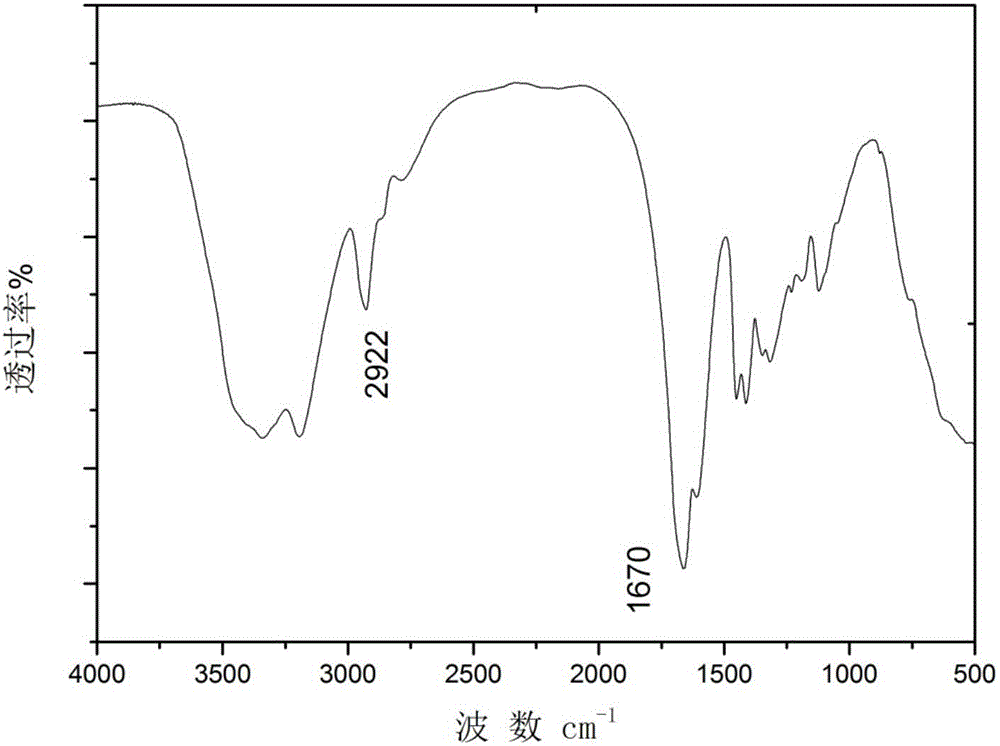

Embodiment 2

[0068] 4g of acryloylethylenediamine hydrochloride was placed in a three-necked flask, and under the protection of nitrogen, the reaction device was placed in high-temperature silicone oil. The temperature was raised to 230° C., the reaction was carried out at this temperature for 8 hours, and then cooled to room temperature. The reaction product was dissolved in 5 ml of deionized water, filtered, and freeze-dried to obtain brown-yellow solid polyacryloylethylenediamine hydrochloride.

[0069] Dissolve 0.1mol of acrylamide and 0.1mol of polyacryloylethylenediamine hydrochloride in deionized water, and 0.1mol of polyacryloylethylenediamine hydrochloride into a four-necked reaction flask equipped with a condenser, mechanical stirrer, and nitrogen inlet. The acid salt was dissolved in deionized water, and added dropwise into the reaction flask through a constant pressure titration funnel to obtain a mixed solution. Nitrogen gas was blown into the mixed solution for 30 minutes, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com