Method for starting and efficiently operating flocculent sludge and granular sludge coexisting autotrophic nitrogen removal system

A technology of granular sludge and flocculent sludge, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve obstacles to application and development, complex bacterial structure, long start-up period, etc. problem, to achieve the effect of promoting enrichment growth, strong sludge adaptability, and short start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

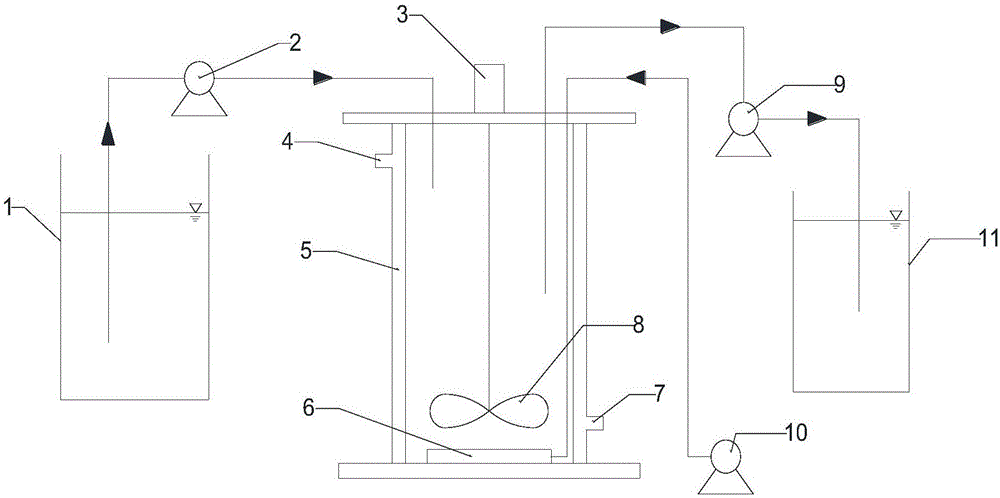

[0030] Example 1, see Figure 1 to Figure 3 :

[0031] The invention provides a start-up and high-efficiency operation method of an autotrophic denitrification system in which flocculent sludge and granular sludge coexist. The reactor is a cylindrical SBR reactor made of machine glass, with a height of 40cm, a diameter of 15cm, and an effective volume of 4L , 2L water outlet each time, the reactor system includes water inlet tank 1, water inlet pump 2, motor 3, water bath layer outlet 4, water bath layer 5, aeration disc 6, water bath layer inlet 7, stirring paddle 8, water outlet pump 9, air pump 10, water outlet tank 11 (attached figure 1 ), using a periodic culture method, comprising the following steps:

[0032] 1) Inoculation ratio setting of flocculent and granular sludge:

[0033] The inoculated sludge is short-course nitrification flocculent sludge and anaerobic ammonium oxidation granular sludge cultivated in the laboratory, and the influent nitrogen load is respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com