Green high-strength and low-temperature composite brazing filler material and preparation method thereof

A composite solder, high-strength technology, used in manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of toxic oxides, environmental pollution, and volatile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

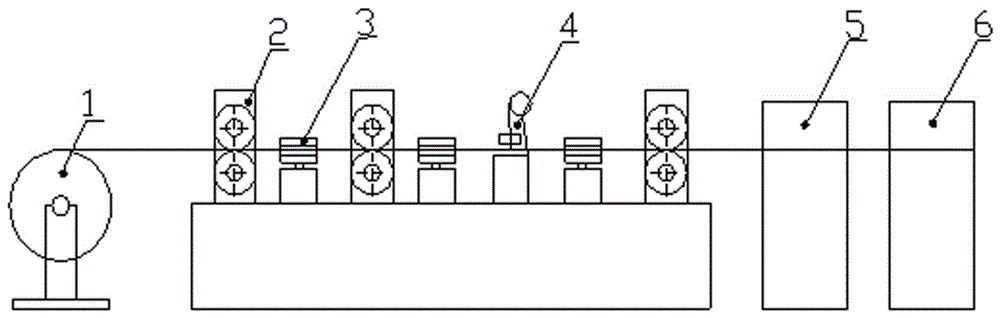

Image

Examples

Embodiment 1

[0021] Example 1: An electrode was prepared by using the following raw materials in weight percentage, wherein: Zn80%, Al10%, Cu0.5%, Li0.5%, In8.48%, Ti0.5%, B0.02%.

[0022] In the first step, the metal Al is prepared into Al wire with a diameter of 0.4 mm through smelting, extrusion, drawing and other processes for use;

[0023] In the second step, the elements B and Ti with higher melting points are prepared into master alloys A and B respectively with Zn. The master alloy A is composed of B5:Zn95 by weight ratio, and the master alloy B is composed of Ti5:Zn95 by weight ratio. Composition: Put the remaining zinc after the preparation of master alloys A and B into an intermediate frequency furnace to melt, add a thin Cu sheet after the temperature reaches 500-600°C, and add the master alloys A and B after fully fused; use cesium fluoroaluminate and Potassium fluoroaluminate compound salt covering, wherein the weight ratio of cesium fluoroaluminate to potassium fluoroalumina...

Embodiment 2

[0029] Embodiment 2: The following raw materials are used to prepare welding rods, wherein: Zn90%, Al1%, Cu5%, Li0.5%, In3%, Ti0.3%, B0.2%.

[0030] In the first step, the metal Al is prepared into Al wire with a diameter of 0.12 mm through smelting, extrusion, drawing and other processes for use;

[0031] The second step to the fifth step are the same as in Embodiment 1.

[0032] Use this electrode to weld H62 brass, the welding temperature is 437°C, and the welding tensile strength is 123N / mm 2 , shear strength 52N / mm 2 , The weld body is not deformed after welding.

Embodiment 3

[0033] Example 3: The following raw materials are used to prepare welding rods, wherein: Zn81.9%, Al3%, Cu3%, Li1%, In10%, Ti1%, B0.1.

[0034] In the first step, the metal Al is prepared into a diameter of 0.2mm Al wire through processes such as smelting, extrusion, and drawing;

[0035] The second step to the fifth step are the same as in Embodiment 1.

[0036] Use this electrode to weld H62 brass, the welding temperature is 430°C, and the welding tensile strength is 133N / mm 2 , shear strength 61N / mm 2 , The weld body is not deformed after welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com