A method for on-line continuous cooling of hot-rolled seamless steel pipes

A technology for seamless steel pipes and steel pipes, which is used in cooling beds, workpiece cooling devices, and metal rolling. The effect of uneven performance of small tissue and improved cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

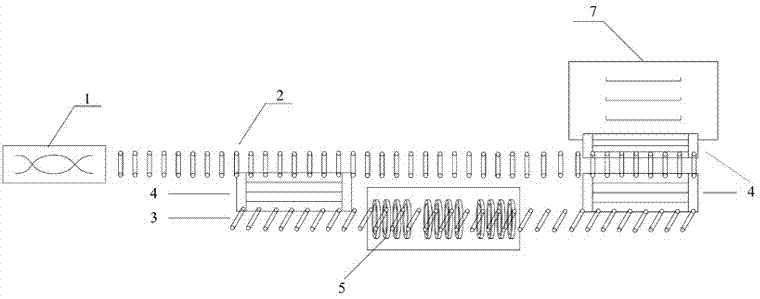

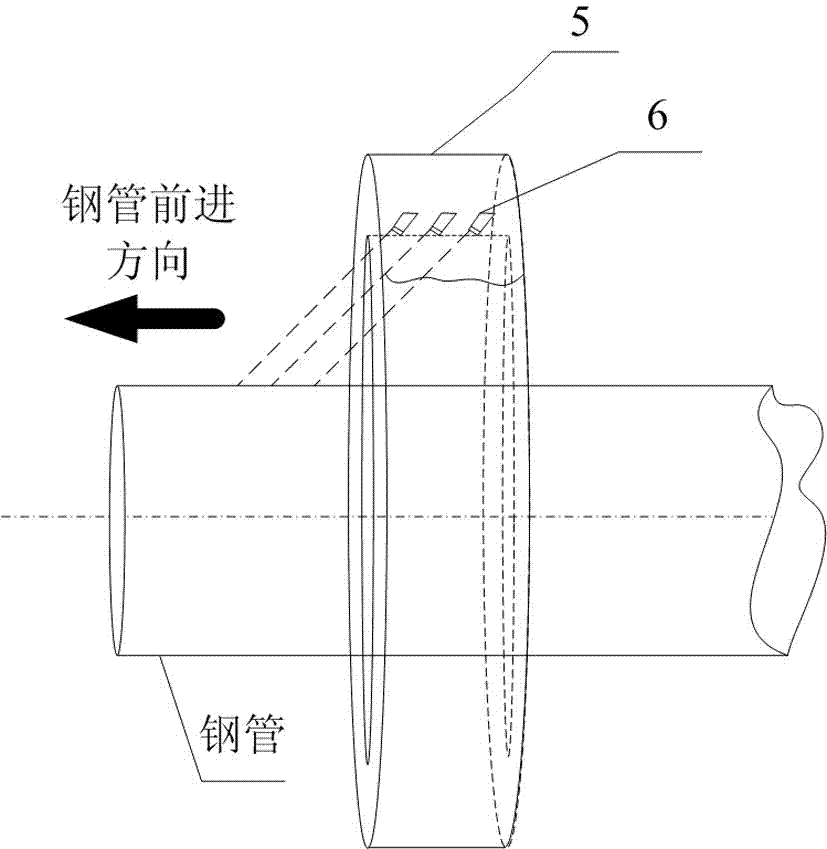

[0027] A method for on-line continuous cooling of hot-rolled seamless steel pipes. The method is realized by a conveying roller table, a pipe turning mechanism, a control cooling device and an automatic control system. The conveying roller table is connected to the straight roller table 2 of the sizing machine 1 And the inclined roller table 3 parallel to the straight roller table 2, the angle between the roller table axis of the inclined roller table 3 and the vertical direction of the steel pipe running direction is 10°, and the inclined roller table 3 directly passes through the Control the cooling device; the pipe turning mechanism 4 is located between the straight roller table 2 and the inclined roller table 3, and is used to transfer steel pipes between the straight roller table 2 and the inclined roller table 3; The control cooling device includes a series of independent circular spray rings 5 arranged in parallel, and the plane structure is as figure 2 As shown, 4 ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com