Anti-adhesion oiling device for surfaces of copper strips and treatment method

An oiling device and anti-adhesion technology, applied in heat treatment furnaces, heat treatment equipment, driving devices for metal rolling mills, etc., can solve the problem of poor surface quality and shape of boiled copper strips, dependence on imports of high-end products, high hardness, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be clearly and completely described below in conjunction with specific embodiments.

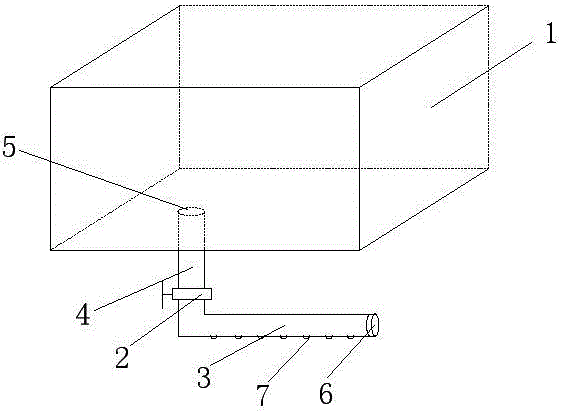

[0034] Such as figure 1 As shown, the copper strip surface anti-adhesion oiling device disclosed in the present invention is used for oiling the surface of the rolled copper strip, including an oil tank 1, an oiling pipeline installed under the oil tank 1, and a valve 2. , The oil-coating pipeline is L-shaped and has a horizontally perforated pipe 3 and a vertical non-porous pipe 4, the bottom end of the oil tank is provided with an oil outlet 5 connected to the non-porous pipe 4, and the end of the perforated pipe 3 The lower end of the perforated pipe 3 is provided with a head 6, and the lower end of the perforated pipe 3 is provided with a plurality of oil outlet holes 7. The oil outlet holes 7 are arranged in a straight line with a diameter of 0.1 cm and two adjacent oil outlet holes 7 The distance between them is 3 cm, and the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com