Non-woven fabric processing and cutting device capable of conducting positioning and use method thereof

A cutting device and non-woven fabric technology, applied in the cutting, transportation and packaging of textile materials, textiles and papermaking, etc., can solve the problem of affecting the pass rate of non-woven fabrics, the cutting device cannot be positioned and cut, and the cutting device does not have the function of positioning And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

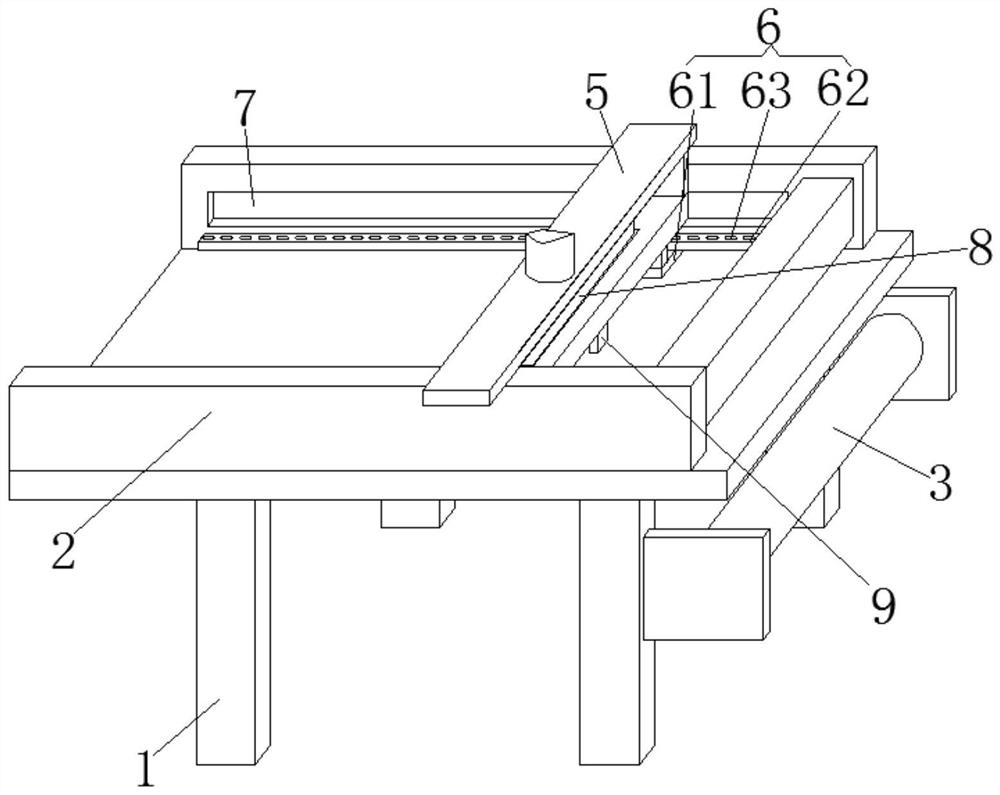

[0022] see Figure 1-3 and Figure 5 , the present embodiment provides a non-woven fabric processing and cutting device capable of positioning and a method of use thereof, including a support platform 1, one side of the support platform 1 is provided with a winding roller 3, and the support platform 1 is used to support the non-woven fabric , The winding roller 3 is a roller shaft structure wound with non-woven fabric in the prior art, and is used as a raw material for the cutting device.

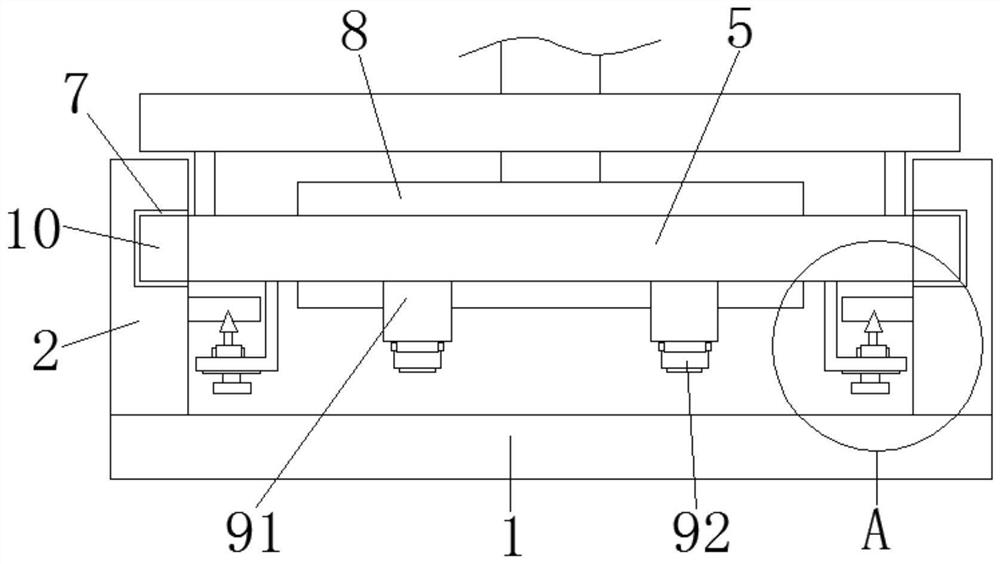

[0023] In this embodiment, in order to enable the cutting knife 8 to move, the upper surface of the support table 1 is fixed with a fixed plate 2, one side of the fixed plate 2 slides a support plate 5, and the upper surface of the support plate 5 is inserted with a cutting knife 8 , there are two fixed plates 2 and they are symmetrical about the transverse central axis of the support table 1, and the opposite sides of the two fixed plates 2 are provided with chute 7, and the two ends of t...

Embodiment 2

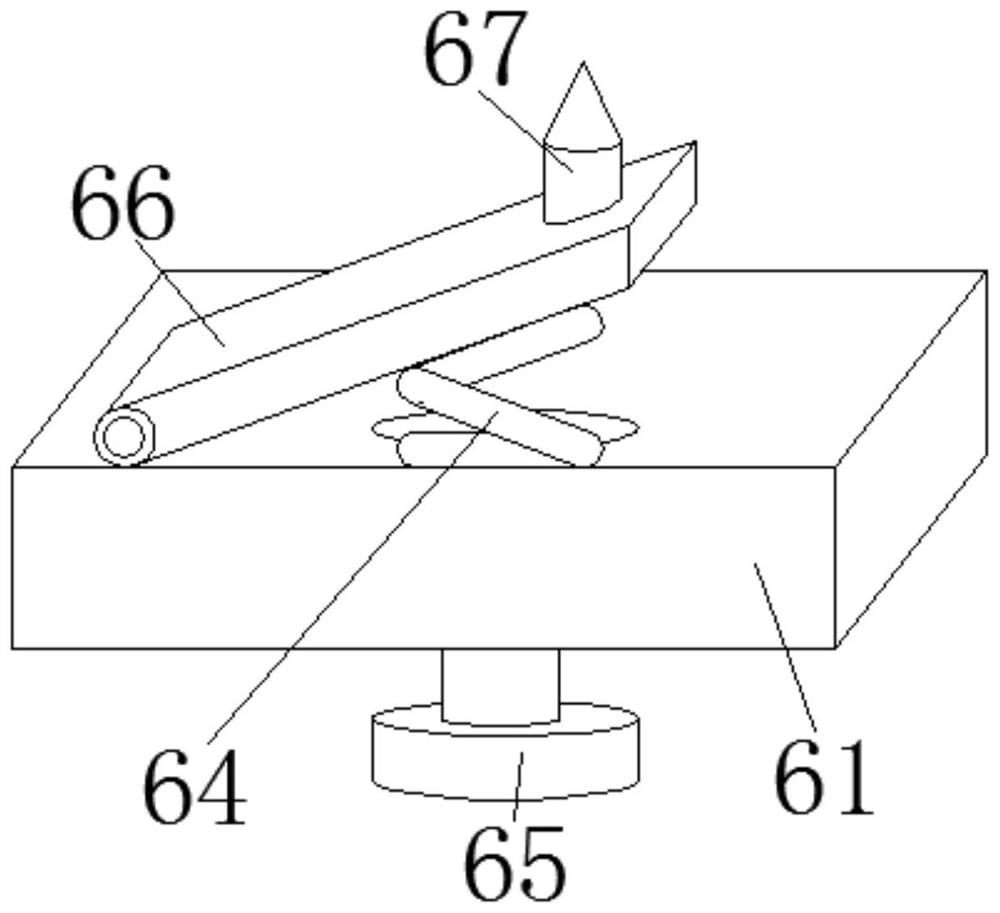

[0035] see Figure 1-4 and Figure 6 , On the basis of Embodiment 1, a further improvement has been made: in order to enable the transmission rod 97 to rotate around the support rod 911, the bottom outer wall of the support plate 5 is provided with a fixing device 9 capable of fixing the non-woven fabric, and the fixing device 9 includes Extrusion block 99, extrusion block 99 is located at the outside of cutting knife 8 and inserted on the inner wall of support plate 5, extrusion block 99 is in the shape of a right angle T, and the hypotenuse of the right angle trapezoid of extrusion block 99 faces upwards, It is convenient for the cutting knife 8 to extrude the extruding block 99 without jamming.

[0036] Wherein, one end of the extrusion block 99 positioned at the inside of the support plate 5 is fixed with a fixed column 98, and the outer wall of the fixed column 98 rotates with a transmission rod 97, and the fixed column 98 plays a position-limiting role, so that the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com