Combined type treatment device for industrial soot waste gas

A processing device and combined technology, which is applied to combined devices, gas treatment, membrane filters, etc., can solve the problems of large structure of processing base station equipment, incomplete smoke and dust treatment, and high maintenance costs, and achieve convenient demolition, low cost, and installation. The effect of short duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

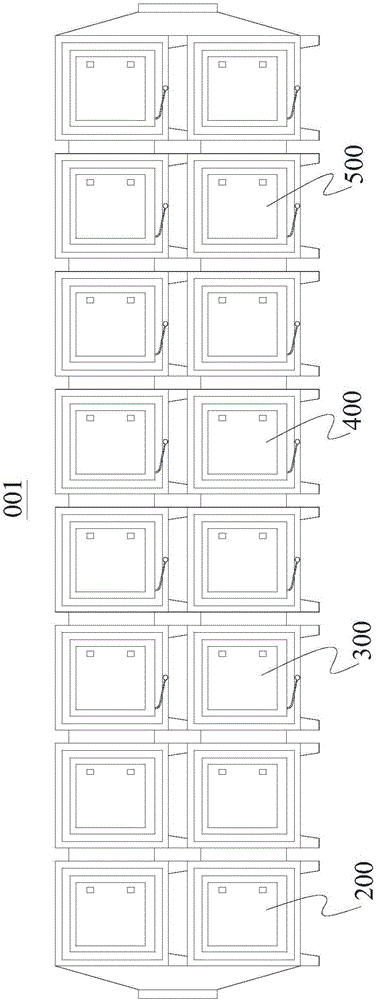

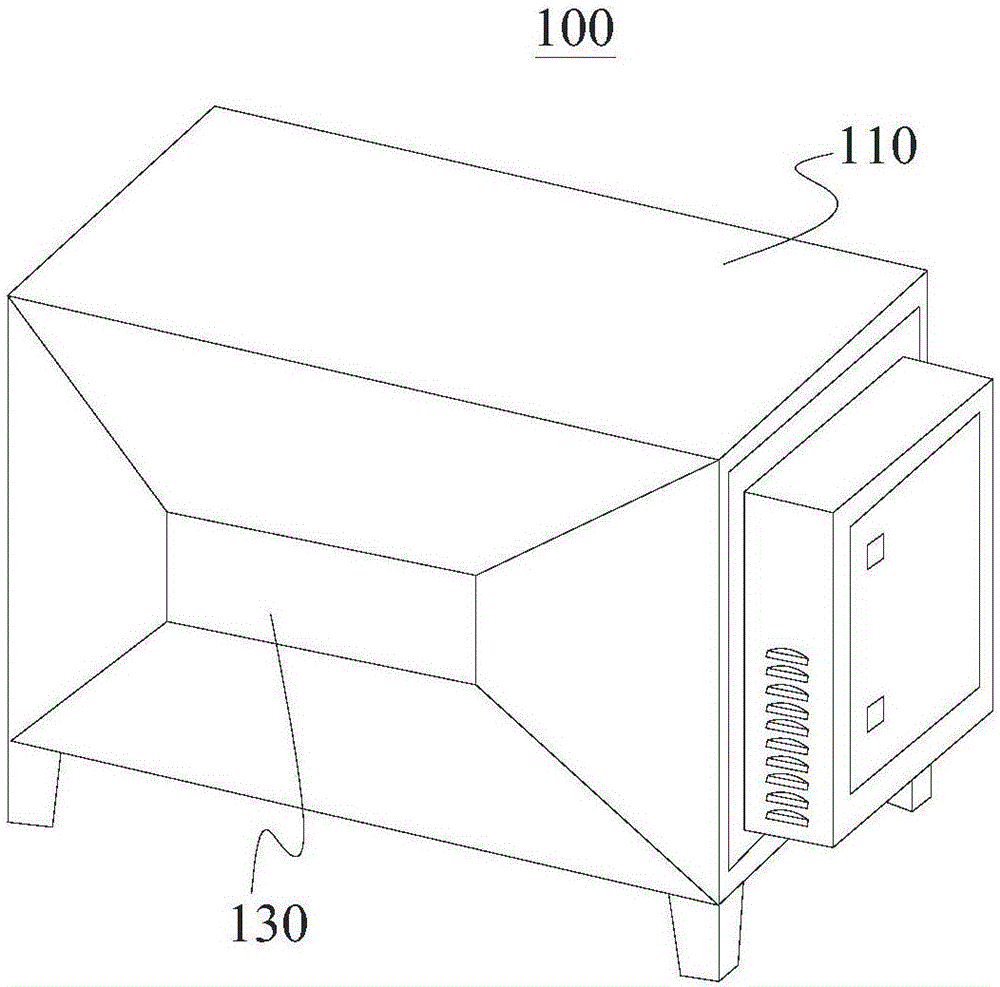

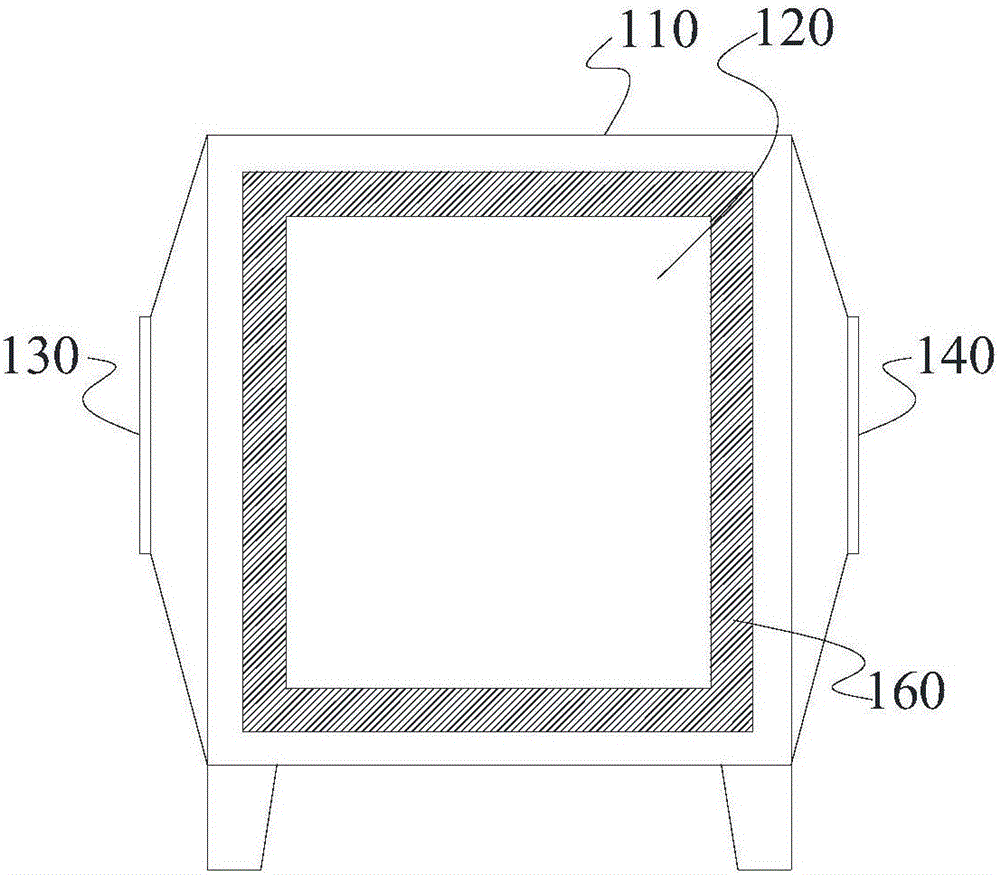

[0055] Please refer to Figure 1 to Figure 3 As shown, the present embodiment provides a combined treatment device 001 for industrial smoke and dust waste gas. According to actual needs (mainly according to the types of smoke particles and other pollutants in industrial waste gas), the pre-filter processing unit 200, plasma The processing unit 300, the high-energy particle tube processing unit 400 and the photocatalyst processing unit 500 are composed of at least one processing unit 100. In this embodiment, devices with different exhaust gas processing functions are modularized to form different types of processing units 100. see figure 2 , image 3 As shown, the general structure of the processing unit 100 is as follows: the processing unit 100 includes a box body 110 and a processing module 120 arranged in the box body 110, and the opposite sides of each box body 110 are arranged in a form that can be opened. The box body 110 is provided with an air inlet 130 and an air o...

no. 2 example

[0078] Please refer to Figure 13 , for the industrial waste gas to be treated is an organic gas containing dust, and the air volume requirement of the industrial waste gas to be treated is 10000m 3 / h, the present embodiment provides a combined treatment device 002 for industrial smoke and dust waste gas, which includes 2 pre-filter processing units 200, 2 high-energy particle tube processing units 400 and 2 photocatalyst processing units 500, pre-filter processing Unit 200, high-energy particle tube processing unit 400 and photocatalyst processing unit 500 are connected sequentially by kind, and the specific structure of pre-filter processing unit 200, high-energy particle tube processing unit 400 and photocatalyst processing unit 500 is identical with that in embodiment 1. The boxes of all processing units are the same, the length of the box is 1m, the width is 0.5m, and the height is 0.7m.

no. 3 example

[0080] Please refer to Figure 14 , for the industrial waste gas to be treated is a gas containing dust, formaldehyde, benzene, toluene, xylene, ammonia, TVOC and other pollutants, and the air volume requirement of the industrial waste gas to be treated is 5000m 3 / h, the present embodiment provides a combined treatment device 003 for industrial smoke and dust waste gas, which includes a pre-filter processing unit 200 and a photocatalyst processing unit 500 connected in sequence, the pre-filter processing unit 200 and photocatalyst processing The specific structure of unit 500 is the same as that in Embodiment 1. The boxes of all processing units are the same, the length of the box is 1.5m, the width is 0.8m, and the height is 1m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com