Applications of composite photocatalytic material, sterilizing and deodorizing shoe-pads and shoes, and preparation methods

A technology of composite photocatalysis and insole, applied in the field of insole, can solve the problems of inconvenience, adverse effects on foot health, easy breeding of bacteria, etc., and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

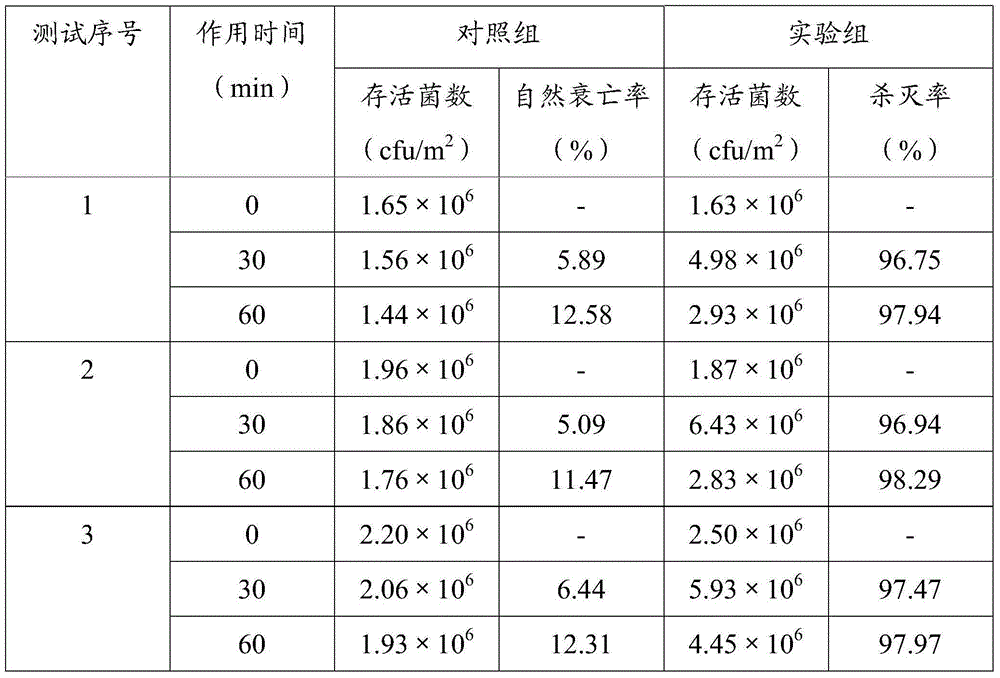

Embodiment 1

[0042]Put a 250mL reaction bottle in an ice bath, add an appropriate amount of concentrated sulfuric acid, add a solid mixture of 2g graphite powder and 2g sodium nitrate while stirring, then add 6g potassium permanganate, stir for 40min, then add 2mL of 30% hydrogen peroxide, continue to stir for 10 minutes, filter while hot, wash with deionized water three times, and dry in a vacuum oven at 60°C for 24 hours. Calcinate the dried solid at 400°C for 2 hours under the protection of nitrogen to obtain reduced graphene powder; add 30 mg of graphene powder to 60 mL of absolute ethanol, and ultrasonically disperse for 1 hour to obtain a graphene dispersion in absolute ethanol. Add 3-5 drops of concentrated nitric acid dropwise, then slowly drop 15mL of n-butyl titanate into the dispersion, continue to stir for 1 hour, then centrifuge the mixed colloid obtained above, and wash it with absolute ethanol several times before putting it in Dry in a vacuum oven at 60° C. for 24 hours, an...

Embodiment 2

[0046] Put a 250mL reaction bottle in an ice bath, add an appropriate amount of concentrated sulfuric acid, add a solid mixture of 2g graphite powder and 1g sodium nitrate while stirring, then add 6g potassium permanganate, stir for 40min, then add 2mL of 30% hydrogen peroxide, continue to stir for 5 minutes, filter while hot, wash with deionized water three times, and dry in a vacuum oven at 60°C for 24 hours. Calcinate the dried solid at 350°C for 3 hours under the protection of nitrogen to obtain reduced graphene powder; add 15 mg of graphene powder to 60 mL of absolute ethanol, and ultrasonically disperse for 2 hours to obtain a graphene absolute ethanol dispersion. Add 3-5 drops of concentrated nitric acid dropwise, then slowly drop 15mL of n-butyl titanate into the dispersion, continue to stir for 1 hour, then centrifuge the mixed colloid obtained above, and wash it with absolute ethanol several times before putting it in Dry in a vacuum drying oven at 50°C for 20h, and ...

Embodiment 3

[0050] Put a 250mL reaction bottle in an ice bath, add an appropriate amount of concentrated sulfuric acid, add a solid mixture of 2g graphite powder and 2g sodium nitrate while stirring, then add 6g potassium permanganate, stir for 40min, then add 2mL of 30% hydrogen peroxide, continue to stir for 10 minutes, filter while hot, wash with deionized water three times, and dry in a vacuum oven at 60°C for 24 hours. The dried solid was calcined at 400°C for 2 hours under nitrogen protection to obtain reduced graphene powder; 60 mg of graphene powder was added to 60 mL of absolute ethanol, and ultrasonically dispersed for 3 hours to obtain a graphene absolute ethanol dispersion. Add 5 drops of concentrated nitric acid dropwise, then slowly drop 15mL of n-butyl titanate into the dispersion, continue to stir for 2 hours, then centrifuge the mixed colloid obtained above, and wash it with absolute ethanol for several times, then put it into vacuum drying The oven was dried at 60° C. fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com