Preparation method of anode material of lithium ion power battery

A negative electrode material, power battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of reducing the first irreversible capacity of natural microcrystalline graphite, affecting the first charge and discharge performance of the material, and unfavorable battery manufacturing process, to avoid Irreversible loss, increased surface property uniformity, effect of surface property uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

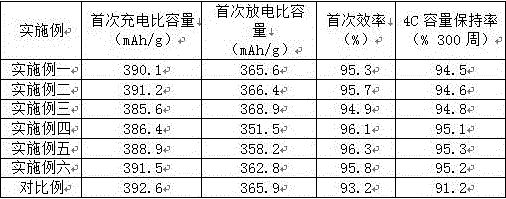

Examples

Embodiment 1

[0040] The preparation method of lithium-ion power battery negative electrode material is characterized in that it comprises the following steps in sequence:

[0041](1) Mix the thermosetting resin and the organic solvent at room temperature at a mass ratio of 1:1. After mixing, add the graphite raw material and stir for 2 hours, then add the curing agent H 3 PO 4 And continue to stir until uniformly mixed, then heat the solution to remove the organic solvent contained therein, and then perform curing treatment at a curing temperature of 78-85°C to obtain a cured thermosetting resin mixture;

[0042] The mass ratio of graphite raw material to thermosetting resin is 1: 0.01; the thermosetting resin is phenolic resin;

[0043] The organic solvent includes a first organic solvent and a second organic solvent composed of a mass ratio of 8:1;

[0044] The first organic solvent is propylene carbonate and triethyl phosphate; the volume ratio of propylene carbonate and triethyl phos...

Embodiment 2

[0061] The preparation method of lithium-ion power battery negative electrode material is characterized in that it comprises the following steps in sequence:

[0062] (1) Mix the thermosetting resin and organic solvent at room temperature at a mass ratio of 1:10, add graphite raw materials after mixing and stir for 4 hours, then add curing agent H 3 PO 4 And continue to stir until uniformly mixed, then heat the solution to remove the organic solvent contained therein, and then perform curing treatment at a curing temperature of 78-85°C to obtain a cured thermosetting resin mixture;

[0063] The mass ratio of graphite raw material to thermosetting resin is 1:0.5; the thermosetting resin is at least one of phenolic resin, epoxy resin and furan resin;

[0064] The organic solvent includes a first organic solvent and a second organic solvent composed of a mass ratio of 10:1;

[0065] The first organic solvent is propylene carbonate and triethyl phosphate; the volume ratio of pro...

Embodiment 3

[0082] The preparation method of lithium-ion power battery negative electrode material is characterized in that it comprises the following steps in sequence:

[0083] (1) Mix the thermosetting resin and organic solvent at room temperature at a mass ratio of 1:7, add graphite raw materials after mixing and stir for 3 hours, then add curing agent H 3 PO 4 And continue to stir until uniformly mixed, then heat the solution to remove the organic solvent contained therein, and then perform curing treatment at a curing temperature of 78-85°C to obtain a cured thermosetting resin mixture;

[0084] The mass ratio of graphite raw material to thermosetting resin is 1: 2; the thermosetting resin is at least one of phenolic resin, epoxy resin and furan resin;

[0085] The organic solvent includes a first organic solvent and a second organic solvent composed of a mass ratio of 9:1;

[0086] The first organic solvent is propylene carbonate and triethyl phosphate; the volume ratio of propyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size distribution range | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com