HEMT epitaxial structure and preparation method thereof

An epitaxial structure, undoped technology, applied in the field of HEMT epitaxy, can solve the problems of independent control of the conductivity of multiple channels, limited output power, and difficulty in multi-channel HEMTs, so as to avoid memory effects and knee points Increase the voltage and improve the leakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

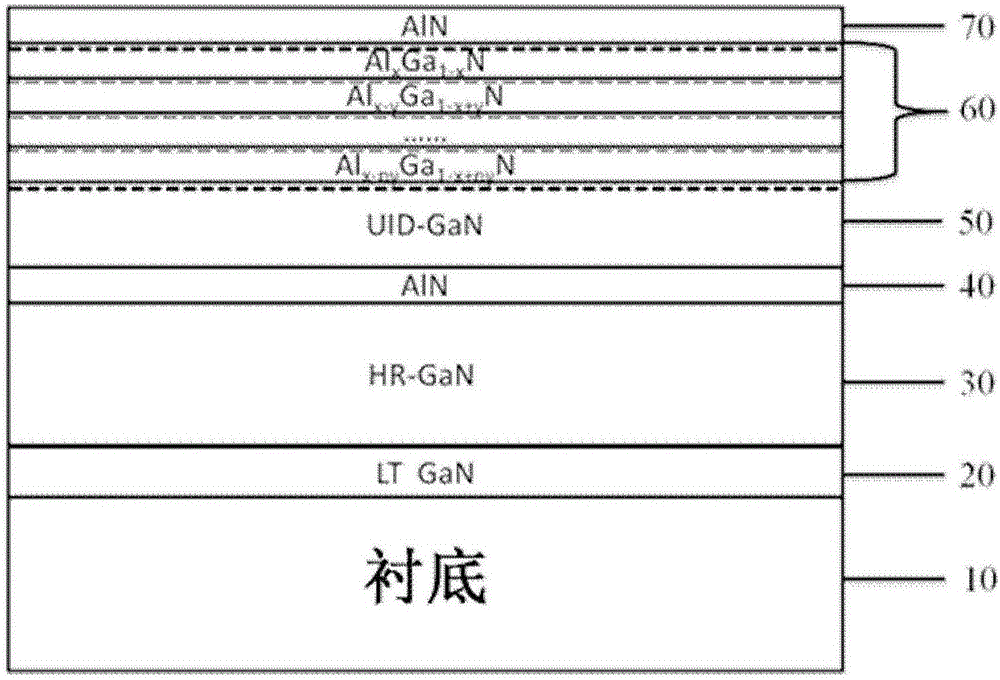

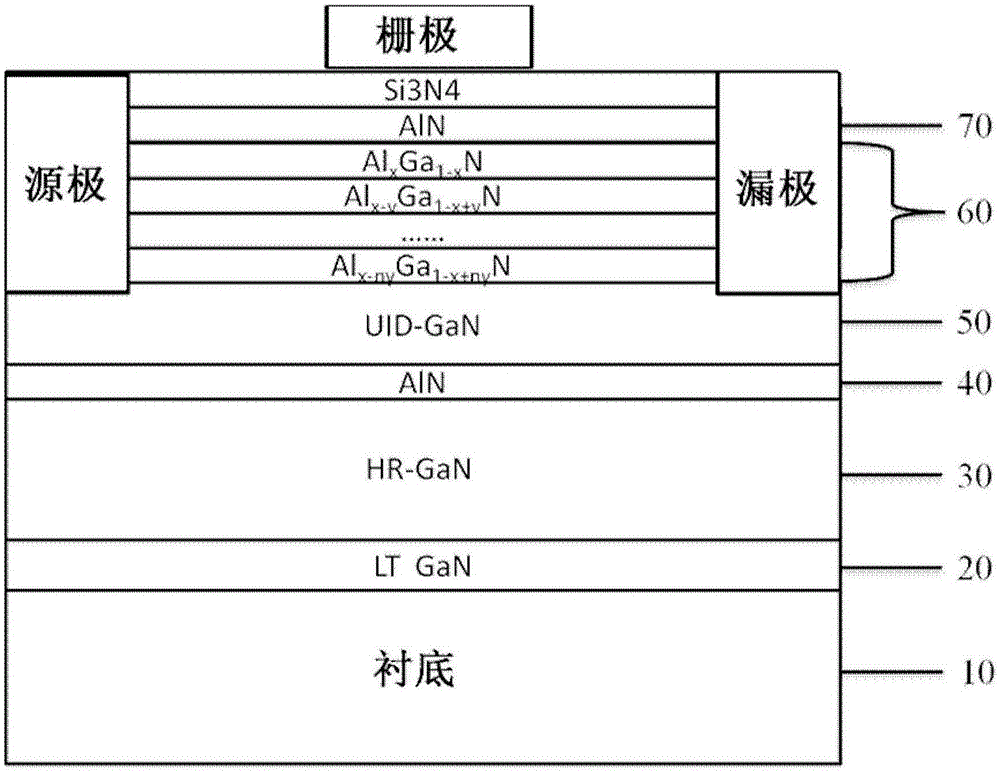

[0029] About the preparation method of the HEMT epitaxial structure:

[0030] Step 1: growing a low-temperature GaN buffer layer on the substrate;

[0031] Step 2: growing an undoped high-resistance GaN layer on the low-temperature GaN buffer layer;

[0032] Step 3: growing an AlN isolation layer on the undoped high-resistance GaN layer;

[0033] Step 4: growing an undoped GaN channel layer on the AlN isolation layer;

[0034] After step 4, a barrier layer with stepwise change in Al composition is grown on the undoped GaN channel layer, and an AlN barrier layer is grown on the barrier layer with stepwise change in Al composition, thereby generating a multi-channel structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com